Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

PRODUCT PARAMETERS

Description

Overview of Protein-based Foaming Agent

The Foam liquid concentrate can be described as a blend of formulas that takes the advantages of protein-based products, and blends these with the flexibility and strength of synthetic straight products.

TR-B (protein-based foaming agent) can be combined with cement slurry to make lightweight concrete that is porous and lightweight. Mix TR-B (foaming agent) with water, separate it from the machine to create foam, and mix it with cement and gypsum mortar in order to make an insulating and lightweight structural component.

Applications of Protein-based Foaming Agent

1) Lightweight concrete production

2) Insulation lightweight block, CLC blocks, wallboard production

3) Heat and sound insulation floor

4) Non-load-bearing wall panels

5) Cement or gypsum board

6) Fill the soil to prevent landslides

7) Underground drainage filling

8) Deicing under bridges and roads

9) Filling of tunnels and shafts

10) Production of thermal insulation lightweight concrete with polystyrene foam particles

11) Pearl Rock Cream Mix

12) Production of lightweight insulation floor and wall in steel structure system

13) Single-story building load-bearing wall

The Advantages of Protein-based Foaming Agent

1. Based on nature, there is no harmful effect on the environment;

2. The high bubble surface membrane has strength;

3. In the case of foam increase, the surface charge can be distributed;

4. Antimicrobial agent effective against mold in concrete;

5. Foam density is adjusted between 80 and 95 g/L;

6. Foam Concrete density 400kg/m3 -1600 kg/m3 needs to be adjusted;

7. The resulting pores provide high insulation for the concrete;

8. Concrete mixing time has no volume loss;

9. Minimum volume loss during pumping;

10. Used with all kinds of cement;

11. It reduces the setting time of concrete. Air temperature 25°C Molding time 5 hours;

12. Stable foam remains upright for about 6 hours.

Parameters of Protein-based Foaming Agent

| Item | Parameter |

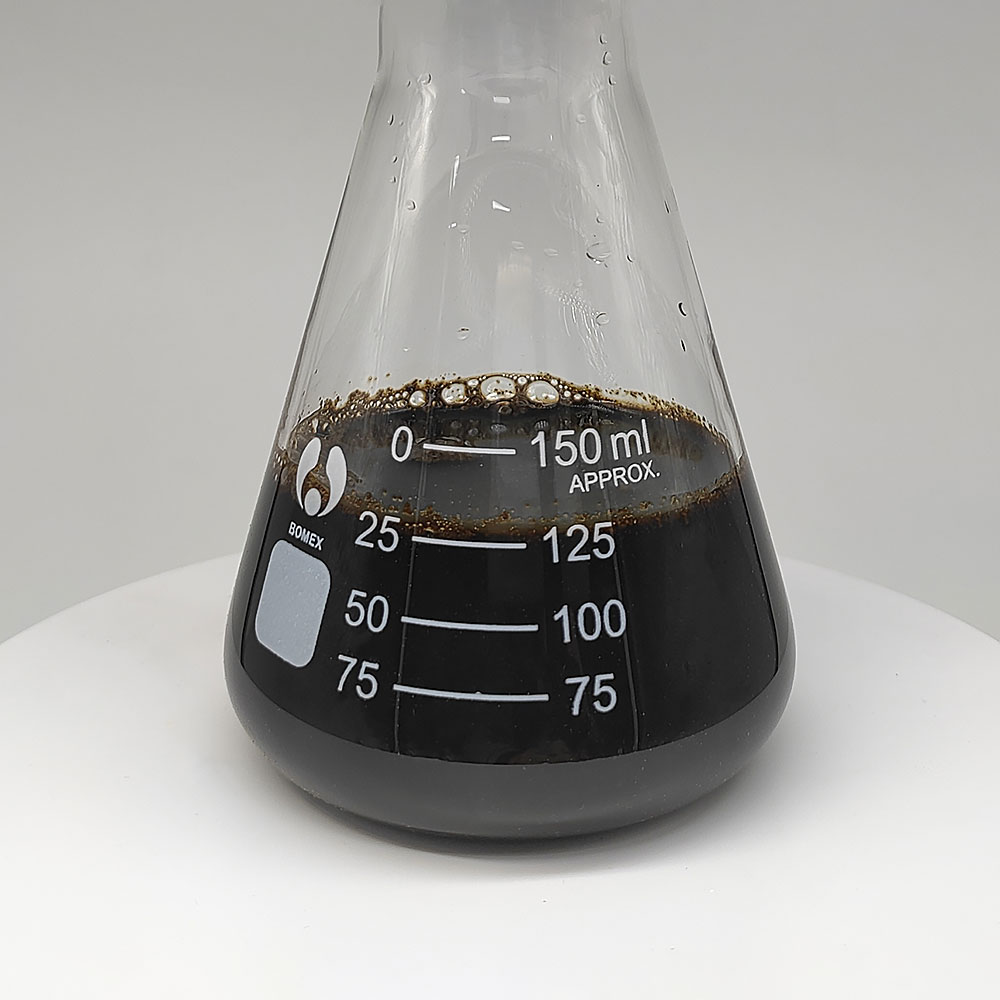

| Apperance | Brown liquid |

| Content | 40% |

| Usage amount(kg/m3) | 0.75-1.25 |

| Foaming multiple | ≥30 |

| Bleeding rate(ml) | 27 |

| Storage method | Store in a cool, dark place to prevent freezing and high temperature. |

| Safety | Non-toxic, non-corrosive, non-combustible, free of formaldehyde, ammonia, heavy metals, halogen |

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012’s.

We can supply high-quality Concrete Foaming Agent such as Polymer Cellular Lightweight Concrete Foaming Agent, TR-C Polymer Foaming Agent,TR-A Concrete Foaming Agent all over the world.

The company has a professional technical department and quality supervision department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.Send us an email or click on the needed products to send an inquiry: sales@cabr-concrete.com.

Package of Protein-based Foaming Agent

25kg/barrel, 200kg/barrel, IBC Tank.

Storage of Protein-based Foaming Agent

Protein-based coconcrete foaming agents should be sealed and stored in a cool, ventilated warehouse at -5℃-25℃.

Payment

T/T, Western Union, Paypal, Credit Card etc.

Shipment

By air, by sea, by express, as customers request.

FAQs of Protein-based Foaming Agent

Q1

How does polymer foam lightweight concrete foaming agent work?

Answer:

Polymer foam lightweight concrete foaming agent releases the gas in the liquid in the form of tiny bubbles through its unique foaming mechanism, forming a large number of uniform and stable bubbles. These bubbles act as physical supports in the concrete, making the concrete lightweight and porous, while also improving the sound and heat insulation properties of the concrete.

Q2

How to choose a suitable polymer foam lightweight concrete foaming agent?

Answer:

Choosing a suitable polymer foam lightweight concrete foaming agent requires consideration of engineering requirements, raw material properties, construction environment and other factors. A brand of polymer foaming agent with appropriate foaming ratio, stability, and good compatibility with cement should be selected, and attention should be paid to its compatibility with raw materials such as sand and gravel. At the same time, product quality and supplier reputation should be considered.

Q3

What issues should be paid attention to when using polymer foam lightweight concrete foaming agent?

Answer:

When using polymer foam lightweight concrete foaming agent, attention should be paid to controlling the dosage and water consumption of the foaming agent to avoid excessive or insufficient effects on the performance of the concrete. At the same time, attention should be paid to the quality stability of the foaming agent and avoid using expired or damp products. During transportation and storage, moisture-proof measures should be taken.

Q4

What impact does polymer foam lightweight concrete foaming agent have on the performance of concrete?

Answer:

Polymer foam lightweight concrete foaming agents have a significant impact on the properties of concrete. It can produce a large number of uniform and stable bubbles, making the concrete lightweight and porous, improving its thermal insulation and thermal insulation properties. At the same time, bubbles play a physical supporting role in concrete and can improve the compressive and flexural strength of concrete. In addition, concrete prepared using polymer foam lightweight concrete foaming agent has good sound insulation and construction properties.

Q5

How is the compatibility of polymer foam lightweight concrete foaming agent with other admixtures?

Answer:

Polymer foam lightweight concrete foaming agent has good compatibility with other admixtures and can be used in combination with other types of admixtures. However, care should be taken to avoid mixing it with some admixtures that have conflicting chemical properties to prevent adverse reactions. Tests should be conducted before use to ensure compatibility meets requirements.

Q6

How to solve the problems in using polymer foam lightweight concrete foaming agent?

Answer:

In the process of using polymer foam lightweight concrete foaming agent, if you encounter problems such as too small or too large bubbles and poor stability, you can appropriately adjust the dosage of the foaming agent or add a regulator to solve the problem. At the same time, strengthening raw material quality control and construction process supervision are also important measures to ensure the effectiveness of use.