Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

Description

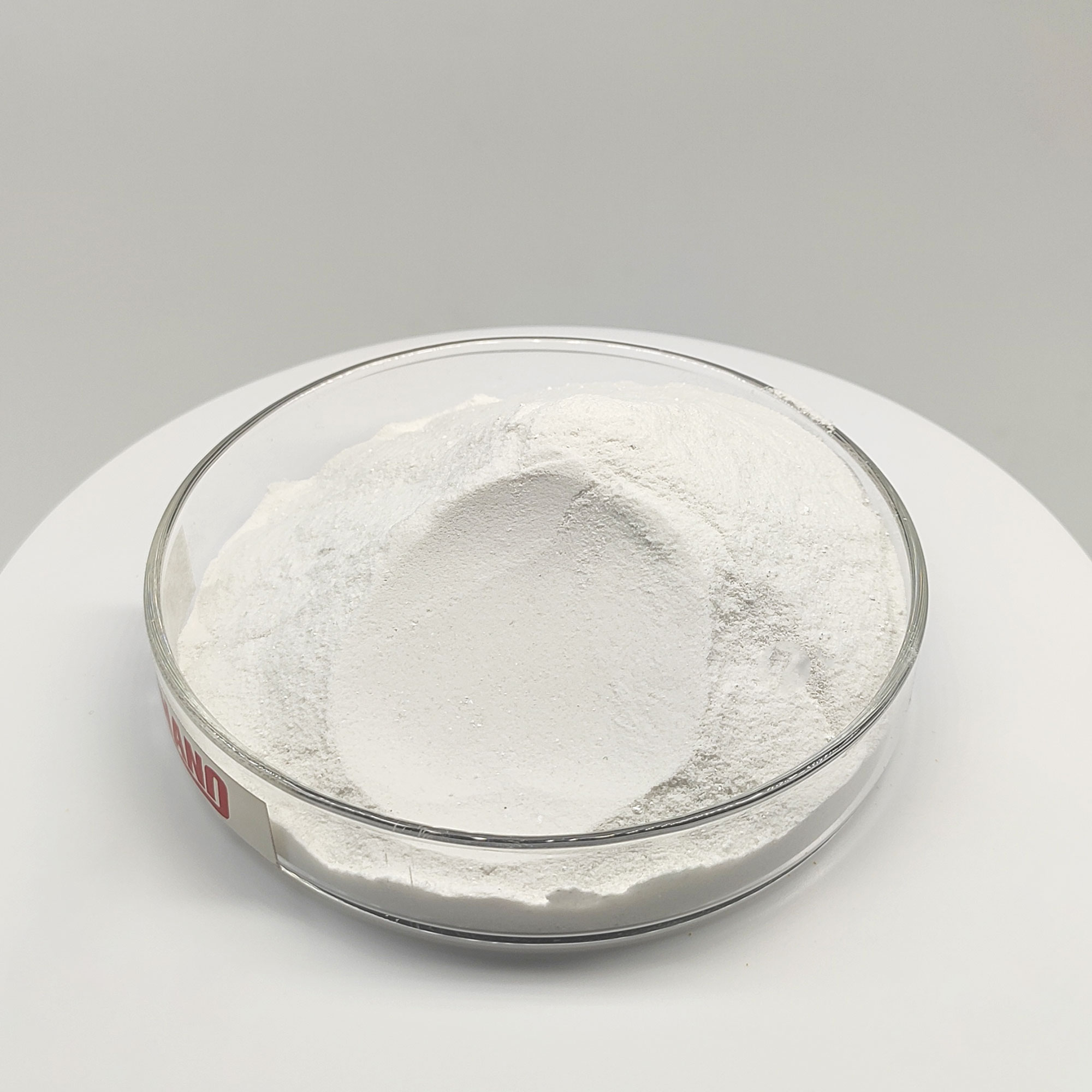

Overview of Concrete Crack-reducing Admixture

Cement anti-crack agents fully utilize the chemical and physical changes that occur in the curing process of cement. The chemically synthesized cement is able to keep cracks and cracks from both chemical and physical factors can greatly increase the strength of concrete that is lightweight.

Anti-cracking agents can efficiently deal with the issue of natural cracking that occurs in cement products. Adding anti-cracking agents to concrete made of lightweight materials can minimize cracks and hollowing on concrete that is lightweight, boost its strength and enhance the overall quality of the construction.

Anti-crack agents solve the issues of large shrinkage deformations, inadequate impermeability and weak resistance to cracks of cement that are used in everyday production. When directly integrated into cement, it is able to efficiently control the shrinkage in plastic and cracks resulting from the segregation of concrete that is lightweight and significantly increasing the strength of concrete made from lightweight materials. cracking properties, anti-freezing performance, anti-shock properties as well as wear resistance and earthquake resistance.

Usage of Concrete Crack-reducing Admixture

Concrete crack-reducing admixture is used to resolve cracks in runways, highways and bridges dams, cement-based products and mortar.

Particularly suitable for different types of concrete with a lightweight structure.

Usage of Concrete Crack-reducing Admixture

Concrete crack-reducing admixture can be used to solve the crack problem of bridges, highways, runways, dams, cement products, and mortar.

Especially suitable for various products of lightweight concrete.

Characteristic of Concrete Crack-reducing Admixture

1) Crack resistance: The crack resistance agent is easily dispersed in lightweight concrete to form a three-dimensional space structure, which effectively improves the phenomenon of reduced hardening and cracking caused by too fast drying of mortar and insufficient moisture;

2) Low shrinkage: The mixture will not shrink and settle, and the anti-crack agent can absorb internal stress and improve crack resistance;

3) Operability: Anti-crack agent can increase the plasticity of mortar, improve construction operability and work efficiency;

4) Anti-slip property: Because the anti-crack agent has a thickening effect, it can prevent or avoid the slippage of mortar and adherend during construction to a certain extent.

Company Profile

Cabr-concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012’s.

We can supply high-quality Potassium Silicate, Gypsum retarder and enhancer, Polyvinyl Alcohol Fiber, Concrete Crack Reducing Admixture, Hollow Glass Microspheres, Concrete strength and shrinkage reducer, Waterproof agent, Redispersible Polymer Powder (RDP) all over the world.

The company has a professional technical department and quality supervision department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.Send us an email or click on the needed products to send an inquiry: sales@cabr-concrete.com

Instructions for Concrete Crack-reducing Admixture

The recommended dosage is 1.5-3kg/m3, and the precise usage needs to be determined after debugging;

When using it, it is best to dissolve the anti-crack agent in the required water and then add it to the mixer to stir, and then it can be used.

Package of Anti-crack Agent

Packaging: The anti-crack agent packaging specification is 20 kg/bag, non-toxic and non-flammable, and can be transported as general cargo. If special specification packaging is needed, it can be customized in advance.

Storage of Anti-crack Agent

The anti-crack agent should be stored in a cool and dry place to avoid rain and moisture, and the shelf life is 24 months.

Payment

T/T, Western Union, Paypal, Credit Card etc.

Shipment

By air, by sea, by express, as customers request.

FAQs

Q1

How to choose a suitable concrete crack reducing agent?

Answer:

Choosing a suitable concrete crack reducing agent requires considering factors such as engineering requirements, concrete mix ratio, and construction environment. Crack reducing agents should be selected that have good compatibility with the concrete materials used, stable performance and significant effects.

Q2

How to use concrete crack reducing agent?

Answer:

How to use concrete crack reducing agents varies depending on the type. Generally speaking, the crack reducing agent should be mixed into the concrete in the specified proportion and mixed thoroughly. In some cases, crack reducing agents need to be added before or during the concrete pour.

Q3

What effect does concrete cracking agent have on the performance of concrete?

Answer:

Concrete crack reducing agents can significantly improve the shrinkage performance, crack resistance and toughness of concrete. The use of crack reducing agents can reduce the drying shrinkage of concrete and increase its tensile strength and toughness, thereby improving the durability and stability of the concrete structure.

Q4

What is the dosage of concrete crack reducing agent?

The amount of concrete crack reducing agent added depends on its type and use. Generally speaking, the amount of crack reducing agent should be within the specified range and appropriately adjusted according to project needs. Excessive use may affect other properties of concrete.

Q5

Are concrete crack reducers compatible with other additives?

Answer:

Concrete crack reducing agents should be compatible with other additives. When using other additives, testing and verification should be conducted first to ensure compatibility and synergy between the crack reducer and other additives.

Q6

What impact do concrete crack reducers have on the environment?

Answer:

Concrete crack reducers have a low impact on the environment. Most crack reducing agents are water-based, contain no harmful substances such as volatile organic compounds, and are environmentally friendly. During use, relevant environmental protection regulations and requirements should be followed.

REQUEST A QUOTE

RELATED PRODUCTS

Lightweight concrete nano-modifier

Chemical RDP powder Polymer powder Redispersible polymer powder shingle adhesive RDP VAE for wall cement

Lightweight concrete nano-modifier

Hydroxyethylcellulose HEC CAS No. 9004-62-0

Sodium Gluconate Concrete Retarder CAS No.527-07-1