Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

(Testing methods for lightweight concrete)

1. Concrete strength inspection

The strength of structural solid concrete should be tested separately according to different strength levels. The test method should adopt the method of curing the specimens under the same conditions; when the strength of the specimens cured under the same conditions does not reach or the strength of the specimens cured under the same conditions is When the requirements are met, the rebound coring method can be used for inspection.

The equivalent curing age during concrete strength inspection can be taken as the age corresponding to when the daily average temperature reaches 600°C·d daily, and should not be less than 14 days. Age periods with daily average temperatures of 0°C and below are not included.

During winter construction, the temperature when calculating the equivalent curing age can be used as the actual curing temperature of structural components, or it can be based on the actual curing conditions of structural components and the strength of the cured specimen under the same conditions is equal to the 28-day age test under standard curing conditions. The principle of strength of parts shall be jointly determined by the supervision, construction and other parties.

Inspection of steel protective layer thickness

The selection of structural solid steel protective layer thickness inspection components should be evenly distributed and should meet the following requirements:

1) For non-cantilever beam panels, 2% of the number of components should be extracted, and no less than five components should be inspected.

2) For cantilevered beams, 5% of the number of parts and no less than 10 parts should be selected for inspection; when the number of cantilevered beams is less than 10, all parts should be inspected.

3) For cantilever plates, 10% of the number of parts and no less than 20 parts should be selected for inspection; when the number of cantilever plates is less than 20, all parts should be inspected.

For selected beam components, the protective layer thickness of all longitudinal stress-bearing steel bars should be inspected; for selected panels, the protective layer thickness of no less than 6 longitudinal stress-bearing steel bars should be selected for inspection. For each steel bar, three representative points should be selected to measure at different locations and the average value should be taken.

The thickness of the steel protective layer can be inspected using the non-damage or partial damage method, or the non-damage and partial damage method can be used for calibration. When using non-destructive testing methods for testing, the testing instruments used should be used for measurement and testing, and the testing operations should comply with the provisions of corresponding regulations. The detection error of the steel protective layer thickness inspection should not be more significant than 1mm.

When inspecting the thickness of the protective layer of steel bars, the allowable deviation of the thickness of the protective layer of longitudinally stressed steel bars should comply with the provisions of the table below.

The thickness of the protective layer of the longitudinal stress-bearing steel bars of beams and plates should be inspected and accepted separately and should meet the following requirements:

1) When the pass rate of the protective layer thickness of all steel bars is 90% or above, it can be judged as qualified;

2) When the qualification rate of the thickness of all steel protective layers is less than 90% but not less than 80%, the same number of components can be selected for inspection; when the qualification rate calculated based on the sum of two samples is above 90%, it can still be determined as qualified;

Inspection of structural position and size deviations

The selection of structural entity position and size deviation inspection components should be evenly distributed and comply with the following regulations:

1) Beams and columns are selected according to 1% of the number of components and no less than 3;

2) Walls and boards should be selected from 1% of representative natural rooms and no less than three rooms;

3) The floor height should be randomly checked at 1% of the representative natural rooms and should not be less than three rooms.

For the selected components, the inspection items and inspection methods should comply with the following table. The allowable deviations and inspection methods should comply with the provisions of Table 8.3.2 and Table 9.3.10 of GB50204-2015, "Code for Construction Quality Acceptance of Concrete Structure Engineering." Accurate to 1mm.

The wall thickness, plate thickness, and layer height can be inspected using non-damaging or partial damage methods, or the non-damaging and partial damage methods can be used for calibration. When using non-destructive testing methods for testing instruments used should be subjected to metrological testing, and the testing operations should comply with the current relevant national standards.

Structural entity position and size deviation items shall be inspected and accepted separately and shall comply with the following regulations

1) When the pass rate of the inspection items is above 80%, it can be judged as qualified;

2) When the pass rate of the inspection items is less than 80% but not less than 70%, the same number of components can be selected for inspection; when the pass rate calculated based on the sum of two samplings is above 80%, it can still be judged as qualified.

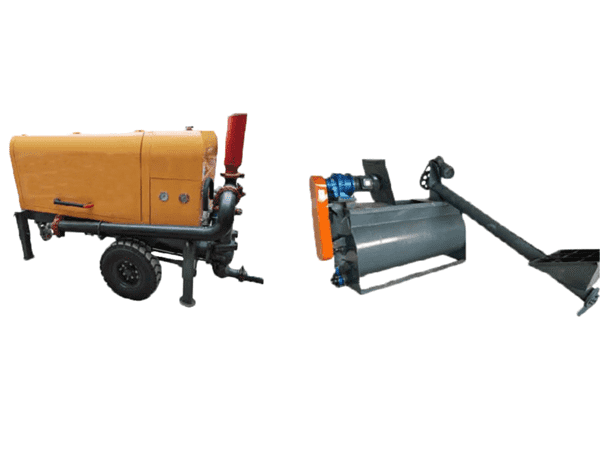

Supplier

TRUNNANO is a supplier of concrete materials with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for high-quality concrete additives, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com).

(Testing methods for lightweight concrete)