Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

(A brief introduction and product indicators of hydroxypropyl methylcellulose (HPMC))

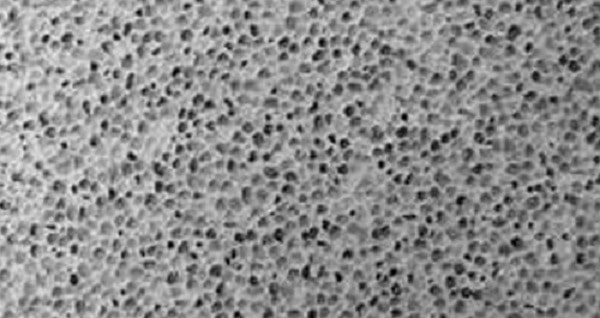

Hydroxypropyl methylcellulose is a white or off-white powder. It is generally used as a dispersant in the manufacturing of polyvinyl chloride. It is also used as a thickener, stabilizer, emulsifier, film-forming agent, and so on in the production of various other petrochemicals, finishings, constructing materials, repaint cleaners, papermaking, cosmetics and other items.

Physical and chemical properties of HPMC

1. Appearance: white or beige powder.

2. Fragment dimension: the pass rate of 100 mesh is more than 98.5%; the pass price of 80 mesh is more significant than 100%.

3. Carbonization temperature level: 280-300 ℃.

4. Evident thickness: 0.25-0.70/ cm3 (typically around 0.5 g/cm3), 5. Certain gravity 1.26-1.31.

6. Discoloration temperature: 190-200 ℃.

7. Surface area tension: 2% liquid option is 42-56dyn/ centimeters.

8. Soluble in water and some solvents.

9. Such as a suitable percentage of ethanol/water, propanol/water, trichloroethane, etc. Aqueous services are surface area energetic. High openness.

10. Stable performance.

11. Products with various requirements have various gel temperature levels.

12. Solubility modifications with viscosity. The reduced the viscosity, the more excellent the solubility.

13. There are specific distinctions in the performance of HPMC with various specifications.

14. The pH value does not influence the dissolution of HPMC in water.

15. As HPMC's methoxy group web content reduces, the gel factor rises, the water solubility decreases, and the surface activity also reduces.

16. HPMC also has the features of thickening capability, salt-tolerant low ash powder, PH stability, water retention, dimensional stability, excellent film-forming properties, and a variety of enzyme resistance, dispersion and bond.

The duty of hydroxypropyl methylcellulose HPMC in concrete

When the content of naphthalene-based superplasticizer rises, the enhancement of the superplasticizer will lower the diffusion resistance of fresh concrete mortar. This is because the naphthalene-based superplasticizer is a surfactant. When the superplasticizer is added to the cannon, the superplasticizer is oriented on the surface of the cement fragments to ensure that the surface area has the same electric charge. This electrical repulsion makes the concrete pieces form. The flocculation framework is dismantled, and the water covered in the structure is released, which will cause the loss of part of the concrete. At the same time, it was located that with the rise of HPMC material, the diffusion resistance of newly blended concrete mortar progressed and improved.

1. The enhancement of HPMC has an obvious retarding result on the mortar mixture. With the boost of HPMC material, the mortar's setting time is successively lengthened. Under the very same material of HPMC, the mortar formed underwater is better than that created by air. Longer setting times for molding. This function is advantageous for undersea concrete pumping.

2. The freshly blended cement mortar combined with hydroxypropyl methylcellulose has excellent natural properties and practically no blood loss.

3. HPMC's web content and mortar's water demand very first decreased and then certainly increased.

4. The addition of water reducing agent boosts the issue of boosting the water demand of mortar. However, its material needs to be reasonably controlled, or else the undersea resistance of fresh blended concrete mortar will sometimes be decreased.

5. There is little difference in framework between the concrete paste specimens mixed with HPMC and the blank samplings, and there is little difference in the framework and density of the concrete paste samplings gathered water and in the air. The samplings formed under water for 28d are a little crunchy. The major reason is the addition of HPMC, which substantially decreases the loss and dispersion of cement when pouring in water. However, likewise minimizes the density of concrete rock. In the project, with the problem of making certain the non-dispersion impact is underwater, the dosage of HPMC should be lowered as much as possible.

6. Adding HPMC undersea non-dispersible concrete admixture regulating the dose is beneficial to the strength. The pilot job reveals that the toughness proportion of concrete developed in water to that developed in air is 84.8%, and the impact is reasonably substantial.

(product indicators)

Dissolution method

1. Take the required quantity of hot water, put it right into a container and heat it to over 85 ° C. Slowly include this item with sluggish stirring. The cellulose floats on the water at first but is progressively spread to create a consistent slurry. Amazing the service with stirring.

2. Or warm 1/3 or 2/3 of the hot water to over 85 ° C, including cellulose, to obtain a warm water slurry, then add the continuing to be quantity of cold water, keep stirring, and cool down the resulting mixture.

The difference between hydroxyethyl cellulose and hydroxypropyl cellulose

1. Different qualities

Hydroxypropyl methylcellulose: white or white-like fiber or granular powder, coming from numerous non-ionic cellulose combined ethers. It is a semi-synthetic, non-active viscoelastic polymer.

Hydroxyethyl cellulose (HEC) is a white or yellow, odorless, non-toxic fiber or powder strong. It is made by etherification of alkaline cellulose and ethylene oxide (or chlorohydrin). It is a non-ionic soluble cellulose ether.

2. Various usages

Hydroxypropyl methylcellulose: As a thickener, dispersant and stabilizer in the coating market, it has excellent solubility in water or organic solvents. PVC is used as a paint eliminator, used in suspension polymerization to prepare PVC, and is extensively used in leather, paper products, vegetables and, fruit preservation and fabric industries.

Hydroxyethyl cellulose: used as the adhesive, surfactant, colloidal safety representative, dispersant, emulsifier and diffusion stabilizer, and so on. It is extensively made use of in the fields of paint, ink, fiber, dyeing, papermaking, cosmetics, pesticides, mineral handling, petroleum recycling and medicine.

3. Various solubility

Hydroxypropyl methylcellulose: Virtually insoluble in outright ethanol, ether, and acetone; soluble in cold water in clear or slightly turbid colloidal solutions.

Hydroxyethyl cellulose: It has the buildings of enlarging, suspending, sticking, emulsifying, dispersing, and moisturizing. It can generate remedies with different viscosity varieties and has excellent electrolyte salt solubility.

Supplier

TRUNNANO is a supplier of hydroxypropyl methylcellulose, which is concrete and relative products with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for high-quality hydroxypropyl methylcellulose, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com).

(A brief introduction and product indicators of hydroxypropyl methylcellulose (HPMC))