Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

(What is Foam Concrete?)

Foam Concrete Composition

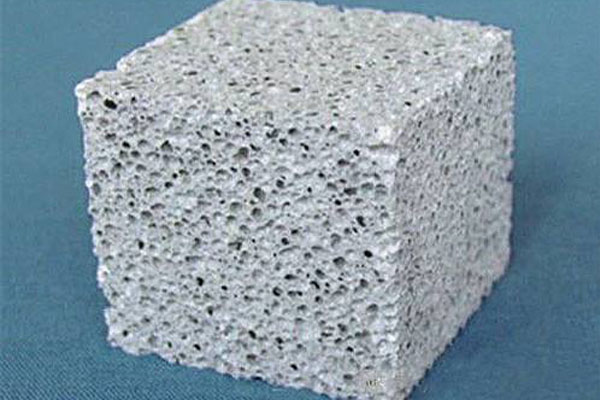

Foam concrete or cellular lightweight concrete (CLC) is made by combining foam with mortar. Mortar is a mixture of cement, sand, and water. Foam concrete is a lighter mixture than standard concrete.

The quality or density of the mortar (weight per cubic meter) depends on the amount of foam supplied. The more foam you add, the lighter it becomes, but also the weaker it becomes.

The ideal mixture has a minimum pressure of 20MPa and a density of 1000kg/m3, but the best results are obtained at densities of 18MPa and 1200kg/m3.

Pure foamed concrete without additives usually has a compressive strength of 5-8MPa and a density of 1000kg/m3.

The lighter the foam concrete, the better the insulation. Foam concrete is a good building material because it combines strength with insulation value.

Foam Concrete Preparation Methods

Typically, foamed concrete is made from cement or a slurry of fly ash, sand, and water, while some suppliers recommend using pure cement and water combined with foaming ingredients to achieve an extremely light mixture.

In the concrete mixing plant, the slurry is further mixed with synthetic inflatable foam. The foaming agent is mixed with the water and air produced by the generator to make foam.

The foaming agent used must be able to produce extremely stable bubbles that are resistant to physical and chemical processes such as mixing, placement, and hardening.

Foamed concrete mixtures can be poured or pumped directly into molds or structural parts. Due to the thixotropy of foam bubbles, foam allows the slurry to flow freely, making it easy to pour into the desired form or mold.

When the steam solidifies at temperatures up to 70 degrees Celsius, the viscous substance can harden in as little as two hours, depending on variables such as ambient temperature and humidity.

When the molded product is cured, it can be removed from the mold.

Foam Concrete Application

Foam concrete has a dry density range of 400-1600kg/m3 and a 7-day strength range of about 1-10N/mm2 (145-1450psi).

Foam concrete is fire-resistant and its thermal and acoustic properties make it ideal for a variety of applications, from floor and roof insulation to void filling.

In addition, it is very beneficial for groove recovery.

The uses of foamed concrete include:

Pipe abandonment/annular filling;

As a precast block;

Trench restoration;

Highway sub-base;

Prefabricated wall elements/panels;

Cast-in-place/cast-in-place wall;

Insulating roof mortar;

Insulation compensation laying;

Insulating floor;

Access to the bridge/embankment;

The concave part is filled.

Concrete Additives Supplier

TRUNNANO is a reliable foaming agents supplier with over 12-year experience in nano-building energy conservation and nanotechnology development.

If you are looking for high-quality CLC foaming agents, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com)

We accept payment via Credit Card, T/T, West Union, and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea.

(What is Foam Concrete?)