Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

(What is Cellular Lightweight Concrete (CLC))

Cellular Lightweight Concrete (CLC)

CLC, or cellular lightweight concrete, is a building material that is used as an alternative to bricks made from red clay. This lightweight material is often used for construction instead of bricks and comes in various forms. Some of these forms are used for onsite usage while others are more appropriate for bulk production.

How do you make CLC concrete?

CLC is a lightweight concrete that meets various specifications. It is commonly used in outdoor walls, partition walls, and building walls. Its lightweight and strong properties make it the ideal material for load-bearing walls in non-earthquake areas. The concrete's density must be between 800 and 1,000 kg/m3. It can be made into smooth blocks or reinforced with steel bars. Cellular concrete blocks are a popular choice for perimeter walls and buildings.

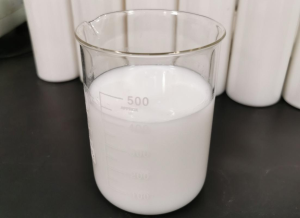

CLC concrete is manufactured by mixing raw materials with a foaming agent, or foam generator, and pumping it into moulds. The concrete is left in the moulds for eight hours before being cut into blocks. It does not need any special machinery to dry. Once it is complete, it is ready for use.

Cellular Lightweight Concrete is available in a range of densities. The lower density CLC blocks are excellent for sound insulating and thermal insulation applications. They are also suitable for structural slabs and filling depressions in the ground. They are also environmentally friendly and help prevent pollution.

CLC is also suitable for load-bearing walls in walk-up apartments. It can support walls up to 15m high. In Haldia, West Bengal, CLC blocks of density 1'400 kg/cum are used. It can be cast in any desired size, making it a great choice for building walls and partitions.

What is CLC material?

Cellular lightweight concrete, or CLC material, is an environmentally friendly material that is lightweight and easy to work with. It is also highly resistant to fires, as the structure is made up of air pockets. The low density of CLC also increases the acoustic insulation qualities of the wall, thereby enhancing its fire resistance. Cellular lightweight concrete is ideal for outdoor walls, interior partition walls, and building perimeter walls.

Its porous nature and smooth surface make it suitable for quick plastering, which reduces the time and labor needed for plastering. Its other benefits include good fire protection, thermal insulation, and sound insulation. And it is completely eco-friendly, as the raw material is made from fly ash. Therefore, CLC blocks are the perfect choice for your construction projects.

CLC is an inorganic lightweight insulation material with a density of 120 to 150 kg/m3. It is non-combustible and more environmentally friendly than traditional insulation. It is available in blocks, panels, and direct-in-place applications. Its non-combustibility could improve the safety of the built environment and reduce the risk of devastating fires in housing developments.

CLC blocks are lighter in weight than clay bricks and concrete blocks, saving time and labor. Moreover, they require less mortar, reducing transportation costs. As a result, CLC blocks are more environmentally friendly than bricks.

What is the weight of CLC block?

CLC blocks can be purchased in various sizes and weights. They can be manufactured by a low-pressure curing system or in a standard autoclave. The block's weight depends on its size and strength. The weight of one CLC block varies between 500 L and 200 H.

CLC is a cement-based lightweight concrete block that has advantages over conventional concrete. Its construction process involves mixing cement, fine aggregates, and a binding material. CLC blocks are lightweight, have a porous structure, and have sharp edges. They can be produced in remote areas without the need for stone aggregates. These blocks are easy to transport by mule.

CLC blocks are an eco-friendly alternative to conventional concrete. Because they are made from recycled materials such as fly ash and industrial wastes, they are free of harmful emissions. These blocks are also excellent at insulating buildings. They reduce energy use in cooling and heating, which reduces electricity costs.

CLC blocks are lightweight, easy to transport, and highly resistant to water absorption. In addition, CLC blocks are very durable and have a high strength-to-weight ratio. Additionally, CLC blocks are easy to handle and require less bonding material than other types of concrete.

Concrete additives Supplier

TRUNNANO is a reliable concrete additives supplier with over 12-year experience in nano-building energy conservation and nanotechnology development.

If you are looking for high-quality concrete additives, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com)

We accept payment via Credit Card, T/T, West Union, and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea.

(What is Cellular Lightweight Concrete (CLC))