Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

(Foaming Agent in Concrete)

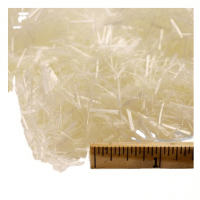

A foaming agent is a liquid that produces air bubbles in a concrete mixture, allowing it to be more lightweight. Foaming agents are used in the manufacture of cellular lightweight concrete (CLC) and other lightweight concrete products.

Several types of foaming agents are available. They vary in density, porosity, stability, and fluidity. The most common ones are synthetic, glue resins, protein based, detergents, resin soap, saponin, and hydrolyzed proteins [2,3,57].

Density of foamed concrete is related to the amount of foam used in the mix. It increases when the proportion of cement decreases and reduces when the amount of foam is increased [5,15,21]. Moreover, porosity and water content are also related to foamed concrete’s compressive strength.

The pore size and pore attachment of foamed concrete are also important in determining its drying shrinkage. This is because a larger pore size can lead to more evaporating water and less shrinkage. It is also reported that the pore structure of foamed concretes increases with increasing density.

Drying shrinkage of foam concrete is also affected by the type and concentration of fine aggregates in the mixture. It is reported that using RCA as fine aggregate has an impact on its drying shrinkage.

The amount of fly ash used in foam concrete also affects its strength development. It can increase the flexural strength and thermal conductivity of foam concrete by improving its pore structure. However, it can decrease the compressive strength when it is used in a high percentage. It can also decrease the workability of foam concrete by reducing its fluidity.

(Foaming Agent in Concrete)