Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

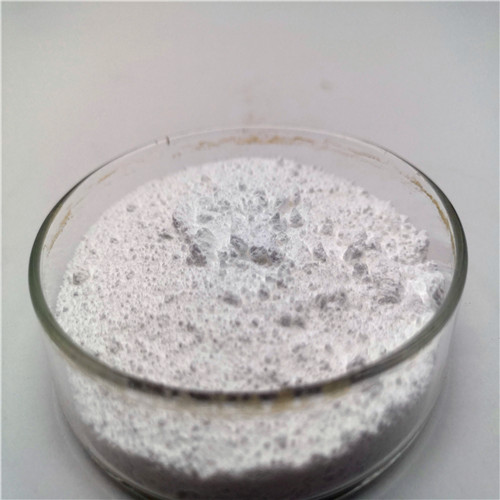

(Concrete Foaming Agent)

concrete foaming agent is a synthetic aerated concrete foam that is produced by mixing it with air and water. This aerated foam is placed on top of the cement and sand mixture to form a lightweight concrete.

Typical uses of foaming agents are:

CLC (cellular lightweight concrete) bricksThe use of the right type of foaming agent makes a huge difference to the performance of the product. This agent reduces the surface tension of the liquid which helps in reducing energy consumption and increases the mechanical properties and strength of the product.

Using the correct type of concrete foaming agent can also have an effect on other concrete properties. The compressive strength and modulus of elasticity are generally linear in relationship to the foam ratio.

Compressive strength

The compressive strength of foam concrete can be affected by several factors such as aggregate type, the filler-cement ratio and mineral additives. Aggregates with a high porosity and fine aggregate types such as RCA have been reported to have negative effects on the compressive strength. Similarly, the use of waste clay brick powder as a coarse aggregate increased water absorption but negatively affected the compressive strength [52].

Modulus of elasticity

The elasticity modulus of foam concrete may vary depending on the aggregate and gradation type. The elasticity modulus is increased when fibers are added to the foam and lowered when the use of fiber is decreased.

Drying shrinkage

The drying shrinkage behavior of foam concrete is dependent on pore structure, namely the void size distribution and pore attachment. Pore size and pore attachment increase with increasing density, which leads to a lower shrinkage rate.

(Concrete Foaming Agent)