Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

(What Is a Release Agent?)

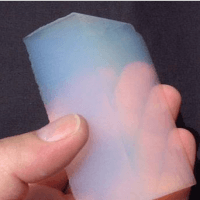

release agent is a coating that is applied to the formwork surface, prior to concrete being poured. This prevents freshly deposited concrete from adhering to the mold or forms and allows the concrete to easily be removed.

A release agent can be used for several different applications, but they are most often used in the food production industry. This can save you time, money and produce high-quality products that don’t get stuck in the baking materials.

In the concrete construction industry, form release agents are used to prevent freshly deposited concrete from sticking to the forming surface, which is typically plywood or layered plywood, steel or aluminum. There are two types of release agents that are used in this application: barrier and reactive.

Reactive release agents undergo a chemical reaction with either the working material or forming surface. This creates a weak boundary layer that dissolves leaving little to no residue.

They also lower the surface energy of the forming surface and decrease surface tension which makes wetting easier.

They are typically water or solvent based and vary in terms of ease of application, production efficiency and cost. Sacrificial (typically waxes and oils) and PVA release agents are the least expensive options, offering adequate slip and chemical inertness but require reapplication each molding cycle. Solvent-based semi-permanent mold release systems deposit a durable coating that allows multiple cycles to be performed before reapplication. They are able to handle a wider variety of temperatures and environments than water-based systems and can be applied on both soft and hard surfaces.

(What Is a Release Agent?)