Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

(Material and Dimensions of CLC Masonry Concrete Brick)

What is clc foaming agent

Foamed concrete is produced by either a pre-foaming method or a mixed-foaming method. The pre-foaming method involves the separate production of a base mix cement slurry (cement paste or mortar) and a stable preformed aqueous addition (foam agent with water), and this foam is then thoroughly blended into the base mix. Dry foam is extremely stable and has a size smaller than 1 mm. Table 2 shows the properties of foamed concrete. The different compositions studied included the use of 200 kg/m3 , 250 kg/m3 , 300 kg/m3 , 350 kg/m3 and 400 kg/m3 of cement. From the research conducted, it was found that the cement composition affects the physical and mechanical properties of concrete masonry bricks, including the success rate of CLC brick making, volume weight, compressive strength and others.The use of different cement compositions of 200 kg/m3 , 250 kg/m3 , 300 kg/m3 , 350 kg/m3 and 400 kg/m3 has an influence on the physical and mechanical properties of the CLC masonry concrete bricks produced. The results of the research show that the average volume weight is 749–895 kg/m3 . The lightest variant is the sample using 350 kg/m3 of cement. The highest compressive strength is found in the sample using 300 kg/m3 of cement. The average modulus of elasticity after 28 days is in the range 45.74–98.64 MPa, and the highest value of the modulus of elasticity was when using 350 kg/m3 of cement.

Material and Dimensions of CLC Masonry Concrete Brick

Cement, as one of the basic ingredients of CLC masonry concrete bricks, is a binder that aggregates granules into a solid form. In using cement as a binding agent, the physical and mechanical properties of the CLC masonry concrete brick are determined by the composition of the cement to be used. Therefore, research is needed to compare the physical and mechanical properties of the CLC masonry concrete brick that is produced. Fine aggregate, as one of the components in cement, must undergo a series of tests on the properties and characteristics of the material. In this study, the type of fine aggregate used is yellow sand (SNI-03-2834–2002), and the qualification limits determined for the fine aggregate are classified into four groups based on the degree of smoothness of the sand material. This research includes sand zone III with a fine modulus of 3.030. The energy consumed in the production of this type of masonry lightweight concrete brick is less than for the production of red brick. This is because CLC masonry lightweight concrete brick is made of a mixture of cement, sand, water, and chemical admixture, to which is then added a foam that is stable in an ordinary concrete mixer. The addition of foam to the CLC mixture creates millions of voids or small cells in the material, which is why it is given the name of CLC masonry concrete brick.

In the manufacturing of concrete masonry bricks

The chemical admixture is usually used in small amounts in the concrete mix. Its use is intended to improve certain properties of the mixture. The materials used are a high-range water-reducing admixture, wherein the material can reduce the water demand of the cement by up to a maximum of 15%. With Sikament LN, the composition uses a dose rate of 0.40% of the total cement requirement of 300 kg, so the quantity needed for this experiment is as much as 1.2 kg. The composition varied among 200, 250, 300, 350, and 400 kg/m3 of cement usage. For lightweight construction in soft soil or peatland areas, innovation is required to reduce the self-weight of the construction. One way to reduce this is by reducing the weight of the walls, which are generally made of red brick having a volume weight of 1,500–2,000 kg/m3, cement brick with a volume weight of 950–1,000 kg/m3 or CLC masonry concrete brick with a lighter volume weight of 400–900 kg/m3. This CLC masonry concrete brick also has the effect of reducing the reinforcement of a structure as a result of the lower section dimensions of the structural elements, and it reduces the amount of concrete, avoiding the usage of sand in the plaster, making the building more economical. CLC masonry concrete brick can be used as an alternative to red brick to reduce environmental pollution and global warming. CLC masonry concrete brick is environmentally friendly.

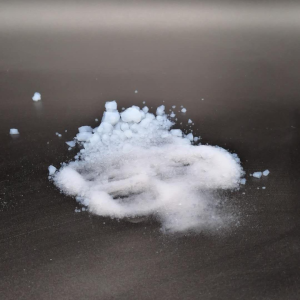

Price of Concrete early strength

Concrete early strength particle size and purity will affect the product's Price, and the purchase volume can also affect the cost of Concrete early strength. A large amount of large amount will be lower. The Price of Concrete early strength is on our company's official website.

Concrete early strength supplier

Luoyang Tongrun Nano Technology Co. Ltd. (TRUNNANO) Luoyang City, Henan Province, China, is a reliable and high-quality global chemical material supplier and manufacturer. It has more than 12 years of experience providing ultra-high quality chemicals and nanotechnology materials, including Concrete early strength, nitride powder, graphite powder, sulfide powder, and 3D printing powder. If you are looking for high-quality concrete additives, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com). We accept payment via Credit Card, T/T, West Union, and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea.

(Material and Dimensions of CLC Masonry Concrete Brick)