Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

PRODUCT PARAMETERS

Description

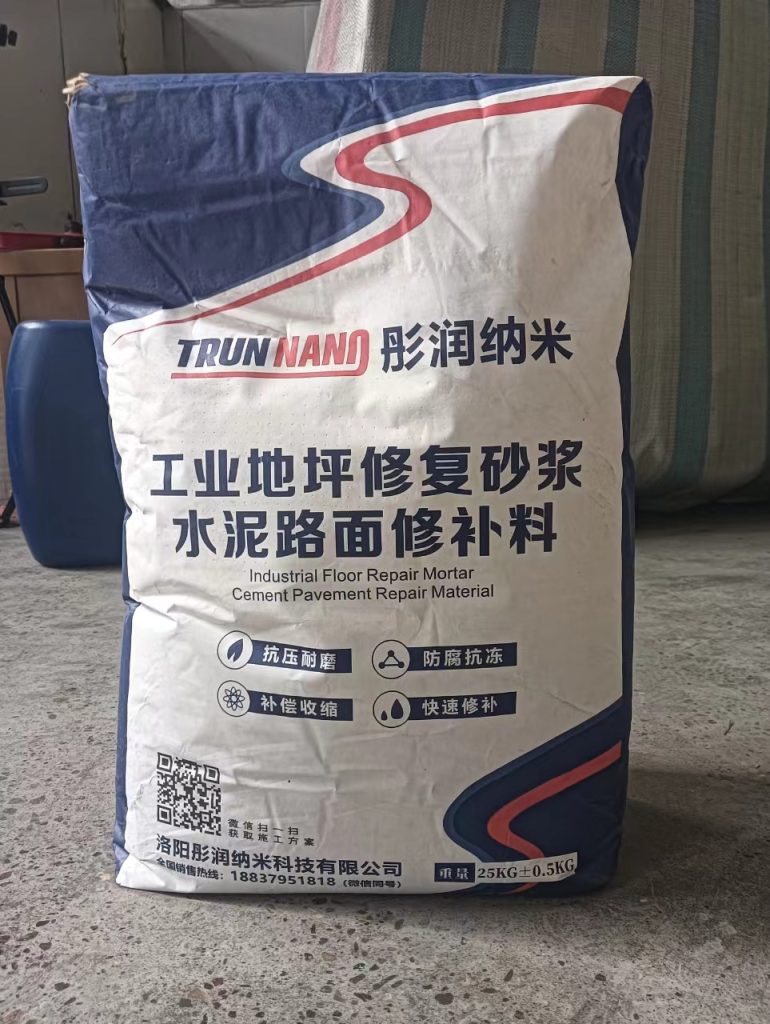

Product introduction] Cement road quick repair mortar

This product is made of special cement, imported polymer, high-strength non-metallic wear-resistant aggregate and a variety of functional additives (anti-segregation agent, reinforcing agent, etc.) refined, with excellent self-leveling performance, high early strength, fast solidification and other characteristics, can be achieved in 2-4 hours of fast traffic. The product has micro-expansion characteristics, effectively avoiding shrinkage and cracking to ensure that the repair surface is durable.

This product also provides quick repair of floor color mortar, regular colors including green, red, blue and other choices, and support for customer-customized exclusive colors to meet the needs of diverse scenes.

Core Advantages

Excellent self-leveling performance, convenient construction

Early high strength, 2-4 hours of fast traffic

Micro-expansion technology, anti-shrinkage non-cracking

Strong abrasion resistance, long service life

Multi-colour options, support for customization

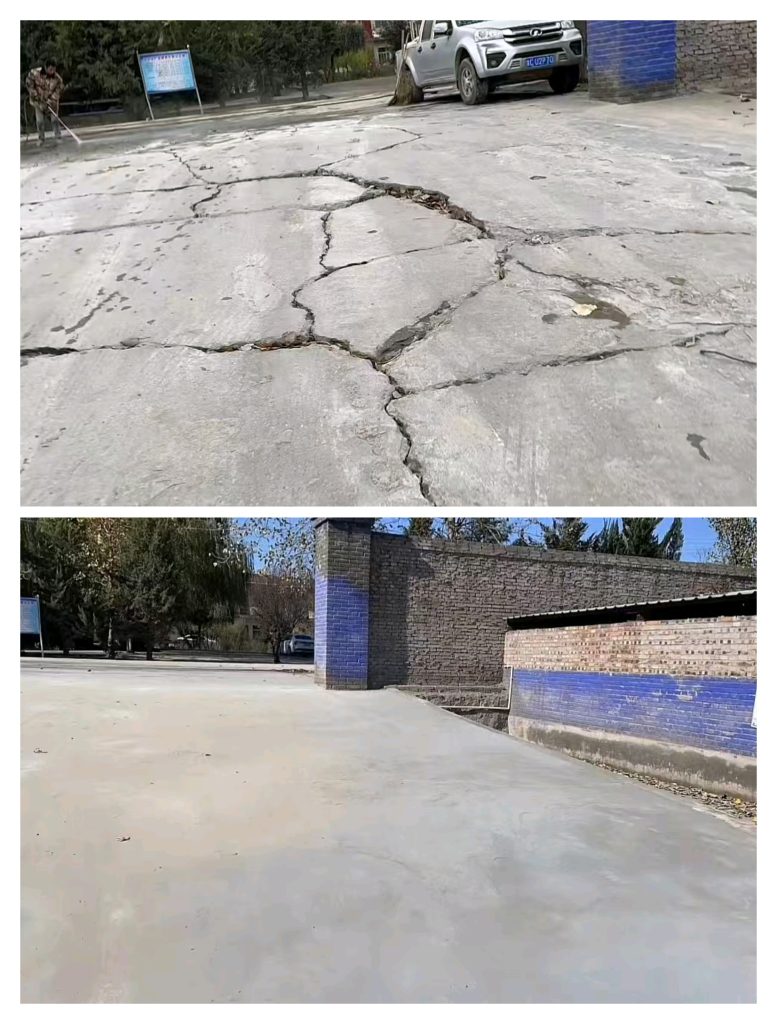

Suitable for municipal roads, factory floors, car parks and other scenes of rapid repair works, it is the ideal choice for high efficiency and economy.

| Project name | Technical indicators | |

| flowability(mm) | starting (point) | ≥260 |

| Coagulation time | condensation | 45min |

| Coagulation time | congeal | 60min |

| Flexural strength(MPa) | 28day | ≥8.0 |

| Compressive strength(MPa) | 24h | ≥20.0 |

| Compressive strength(MPa) | 28day | ≥60 |

| Bonding strength(MPa) | 28h | 1.7 |

Construction method and process (construction recommendations: large area construction, milling machine to mill the ground in the original foundation expansion joints above the cut expansion joints)

Step 1: clean up: with a high-pressure water gun or broom, clean up the ground on the floating dust, gravel, loose surface layer, debris, etc., after flushing clean, to ensure that the construction of the ground is no dust or gravel.

Step 2 Wet: the ground with a high-pressure water gun or hose to soak the ground; the ground soaked without bubbles until (about 10-20 minutes), after washing the use of a mop or a blower gun, clean the ground

After soaking, use a mop or a blower gun to clean up the open water on the ground. The ground can be kept wet, but there should be no open water.

Step 3: add water and mix: a bag of 25 kg of material, the amount of water 4-4.5 kg of water (must not add more). Use an electric drill or stand mixer to mix well, 3-5 minutes can be used.

Step 4 paving: pour the stirred material on the ground to lighten and smooth, the thickness of 3-5 mm, the operating time of 10 minutes or less, 2 hours after the solidification of the pass.

Operation precautions

Before Construction.

Smooth/oil stained/severe anti-sand/loose surface ground: Wash the ground with a washing machine to enhance the bonding force.

Potholes/cracks in the ground: first repair potholes and cracks, leveling and then do the surface; the ground must be wet through, with no bubbles until. There should be no open water on the ground.

If the ground is not wet through the bubble, perforation will occur

If the groundwater is not cleaned up, it too dilute, making the surface layer more flowers, affecting the bonding force

Good fluidity of the material, once through, without repeated polishing

It is recommended to use an interface agent to deal with the grassroots so that the concrete and the product bonded firmly, in accordance with the proportion of strict control of the amount of water, to avoid affecting the strength of the mortar and condensation time.

Packaging and storage

Packed in composite bag, weight (25kg±0.5kg)/bag. Stored in an indoor ventilated dry environment, pay attention to moisture.

Shelf life 6 months

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012’s.

We can supply polyethylene fibre (PVA fibre) all over the world. We have a professional technical department and quality supervision department, a well-equipped laboratory with advanced testing equipment and an after-sales customer service centre. Please send us an email or click on the required product to send an enquiry.

If you want to know more about Pavement Repair Mortar please feel free and contact us: sales1@cabr-concrete.com

Payment

T/T, Western Union, Paypal, Credit Card etc.

Shipment

By air, by sea, by express, as customers request.

REQUEST A QUOTE

RELATED PRODUCTS

HPMC Hydroxypropyl Methyl Cellulose

Introduction to water-based mold release agents

Special Cementitious Material TR White Super High Strength Fast Hardening Sulphoaluminate Gelling Agent For Cement Concrete use

Sodium Gluconate Concrete Retarder CAS No.527-07-1

industrial design Equipment for making foam Foaming machine