Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

PRODUCT PARAMETERS

Description

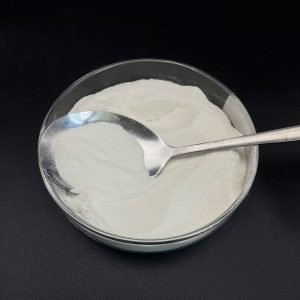

TR-BW-A Polymer Vegetable Protein Cement Foaming Agent

Core Advantages

Environmentally friendly and economical formula with excellent foaming efficiency

Perfect compatibility with silicate cement

High stability of foam to meet the needs of large-volume construction

Multi-scenario, easy to apply

| sports event | / |

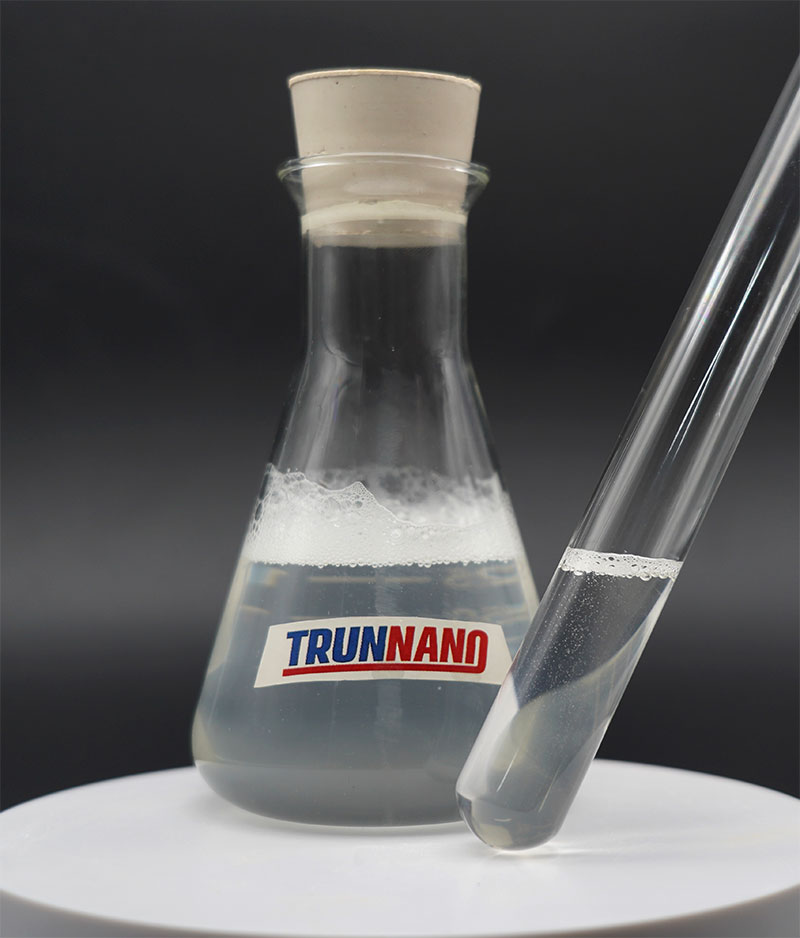

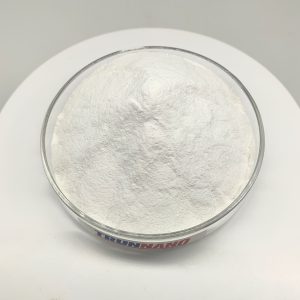

| Product Appearance | transparent liquid |

| Density (g/ml) | 1.1±0.02 |

| Solid content, % | 25±1 |

| Water secretion rate (g/l) | 13±0.1 |

| Foaming times | 30 |

| Sinking distance (mm) | ≤10 |

| PH | 8-9 |

| Recommended dilution ratio | 1:30/40 |

| Working temperature | 10-60 |

Product Description: TR-BW-A is a white transparent liquid developed by Tongrun.

The TR-BW-A foaming agent is a white transparent liquid developed by Tongrun, adopting high polymer plant protein air-entraining agent as the core raw material, specially designed for cement-based foaming systems. The product has the following characteristics:

Excellent foaming performance: it can quickly generate uniform and fine foam to meet the demand of large-volume foam concrete production;

Excellent compatibility: excellent compatibility with ordinary silicate cement, ensuring the structural stability of products;

Long-lasting foaming effect: strong foam stability, effectively reducing the defoaming rate during the pouring process;

Environmentally friendly and economical: plant-based components are more ecologically friendly, and the cost performance is better than traditional foaming agents.

Application areas

1 Foam concrete block production

2 Underground backfill and insulation layer construction

Product characteristics

Economical and efficient: low additive amount of foaming agent (1-2kg/m³), high foaming multiplication, comprehensive cost reduction of more than 20% compared with similar products.

Wide-spectrum application: it is suitable for ordinary Portland cement and can be widely used in roof insulation layers, cast-in-place filling, lightweight block and other scenes.

Stable performance: Foam retention rate of more than 85% at room temperature (0℃+), and the dosage needs to be increased appropriately for low-temperature working conditions.

Convenient operation: 30-40 times water dilution can be used through the foaming machine.

Application fields

a Building roof insulation layer construction

b Foam concrete cast-in-place filling project

c Lightweight partition wall panels and block production

d Underground pipe corridor backfill and roadbed repair

Technical Parameters

Working temperature: above 0℃ (low temperature needs to be tested and verified)

Dilution ratio: liquid:water=1:30-40 (volume ratio)

Dosage standard: 1-2kg original liquid/m³ concrete

Storage requirements: cool and ventilated environment, avoid freezing (storage temperature 5-35 ℃)

Packing specification

Standard package: 25kg/drum, 200kg/drum, 1000kg/drum.

Customized service: Support unique packaging specifications and logo customization.

Cautions

When matching with other cement varieties, it is recommended to test small samples first.

Winter transport needs to take anti-freezing and heat preservation measures.

It is recommended to use it up within 6 months after opening.

(Note: This product has passed ISO9001 quality management system certification)

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012’s.

We can supply polyethylene fibre (PVA fibre) all over the world. We have a professional technical department and quality supervision department, a well-equipped laboratory with advanced testing equipment and an after-sales customer service centre. Please send us an email or click on the required product to send an enquiry.

If you want to know more about Roof Insulation Foam please feel free and contact us: sales1@cabr-concrete.com

Payment

T/T, Western Union, Paypal, Credit Card etc.

Shipment

By air, by sea, by express, as customers request.

REQUEST A QUOTE

RELATED PRODUCTS

sodium silicate

Milling Steel Fiber Mill-Cut Hooked Concrete Steel Fiber Concrete Binder Architecturally Acicular Steel Fiber

Sodium Gluconate Concrete Retarder CAS No.527-07-1

Factory Row Steel Fiber Price for Row Steel Fiber Concrete Hot Sale

Chemical RDP powder Polymer powder Redispersible polymer powder shingle adhesive RDP VAE for wall cement