Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

(Add foam to cement? After seeing it, he became very angry. However, he realized that he had wrongly blamed the worker after figuring it out.)

What is the effect of adding foam to cement?

When some owners go to inspect the decoration and see the master workers adding foam to the cement, many people will get angry and think that the master workers are cutting corners. This is just for a layman. In fact, the practice of adding cement to foam has already been done for a long time. It's called foamed cement, also called foam concrete, and a new insulation material.

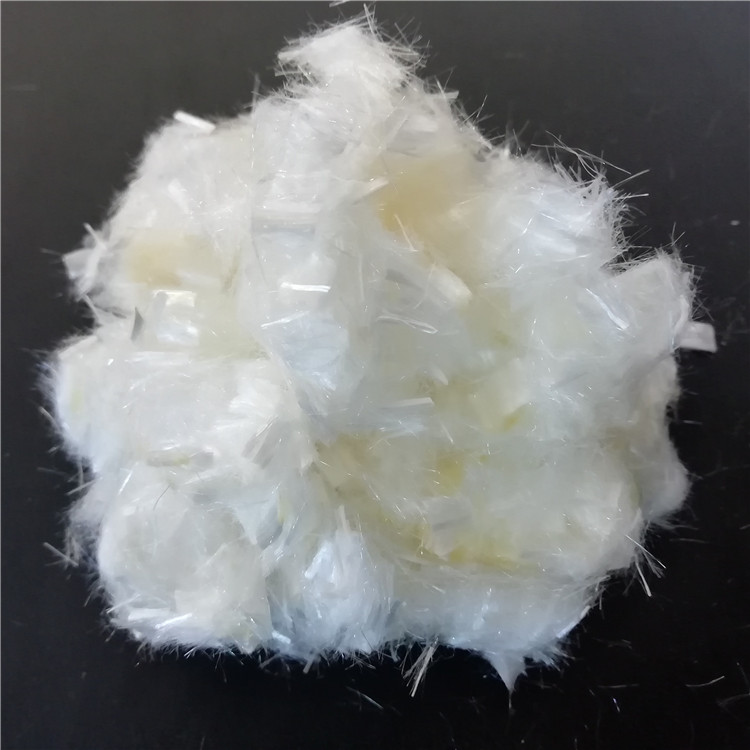

Foamed cement is a new type of lightweight insulation material that is made by mixing cement slurry and foam to form a large number of pores naturally. What are the advantages of foamed cement as a new material?

1. First of all, due to foaming, it is lighter than ordinary concrete in the same volume, one-sixth of it! The density is more minor, reducing the load!

2. A large number of small pores can have a good thermal insulation effect. Nowadays, many people install floor heating, and the floor will be made of foamed cement!

3. Still because of the pores, it has good sound insulation function, just like the materials used in KTVs, concert halls, etc.

4. The water absorption rate is low and the closed bubbles are independent, giving it a good waterproof effect.

5. Foamed cement is an inorganic material with good fire resistance and will not burn, which improves the fire resistance of the building.

6. Can be produced directly on site. Just use cement and foaming agent. It is quick and easy to use, and it does not contain harmful and toxic substances such as formaldehyde and benzene, which protects the personal health of the owners!

7. Good durability and long service life.

What are the advantages of foamed cement?

Use foamed cement to make an insulation layer, which is used for roof insulation and exterior wall insulation. It can replace other insulation materials such as polystyrene (styrene board). It has unparalleled insulation performance and structural layer adhesion performance and is easy to construct. , environmental protection, time saving, efficiency improvement and many other advantages. This technology is very popular in South Korea and is also widely used in northern coastal cities in China, achieving good thermal insulation effects. This technology has begun to become popular in western China. Foamed cement is also used in southern China to make foamed cement bricks to achieve the effects of roof insulation and exterior wall insulation.

Technique has actually verified that frothed concrete has excellent thermal insulation, warmth preservation, audio insulation, light load-bearing and other homes, and transcends to various other lightweight strong plastic increased perlite, ceramsite, asbestos products and various other insulation materials. It is very easy to operate, has a high degree of automation, and is time-saving., labor-saving features. Lathered cement can be carried by mechanical upright pipes, which reduces the working hours and improves work efficiency by 6 to 10 times compared to various other methods.

Utilizing foamed cement as the roofing insulation material substantially boosts the bonding and adhesion between the insulation layer and the floor base. In the past, most flooring heating construction uses benzene board as the insulation layer, which can not be well integrated with the original base surface. It has no reliable adhesion, triggering delamination, hollowing, splitting, etc. The foamed concrete body is used as the thermal insulation layer to ensure that the foamed cement thermal insulation layer can fill up the little uneven base surface of the initial floor slab and can be securely understood to form a strong adhesion performance. After building and construction, the original surface layer will get to a level degree, which will ease the following process and guarantee the total result of the consistent density of the surface layer.

What are the uses of foamed cement?

1. Foamed cement is mainly used in retaining walls, especially rock walls in ports, because its good rigidity reduces the strong lateral load on the shore, does not exert lateral pressure on the evolving shore wall, and reduces settlement. Therefore, maintenance costs have also been reduced, saving a lot of expenses to a certain extent.

2. Foamed cement is also used in the construction of track and field runs and sports fields. Foam concrete with strong drainage properties can be used as the foundation and covered with artificial turf to serve as sports fields.

3. Thermal insulation of buildings is the main field of foamed cement, currently accounting for 80% of the total output. Because of its good thermal insulation performance and the policy of building energy conservation, it has been widely used in areas of building thermal insulation.

4. Foamed cement also has great market advantages in wall sound absorption. Its advantages are good strength and low price. It is also used on the walls of subways, large shopping malls, cinemas, conference halls and other building walls market.

Supplier

TRUNNANO is a supplier of foaming agent of concrete and other additives, which is concrete and relative products with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for high-quality foaming agent of concrete and other additives, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com).

(Add foam to cement? After seeing it, he became very angry. However, he realized that he had wrongly blamed the worker after figuring it out.)