Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

(Applications of Foam Cement (2))

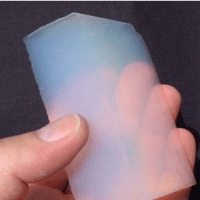

What is Foam Cement?

Foam cement is a new type of lightweight thermal insulation material containing a large number of closed pores. It is to use mechanical method first concrete foaming agent full foaming, then foam and cement mud even mixing, cast-in-situ construction, or through the pumping system of foaming machine molding and become. Finally, after natural conservation, formed.

It belongs to a bubble insulation material. Its outstanding feature is the closed foam hole inside the concrete can make the concrete lightweight, heat preservation, and heat insulation.

Applications of Foam Cement

9. For wall pouring on site.

Foam concrete is used as a non-load bearing wall of buildings by foaming and pouring on-site, which changes the common method of the precast block building wall. The wall integrity is good, the construction is simple, the labor intensity is small, and the cost is low. At the same time, it has the advantages of being lightweight, heat insulation, waterproof and seepage prevention, etc. It is an alternative product to the traditional wall.

10. Foam concrete can also be used for firewall insulation filling, sound insulation floor-filling, tunnel lining backfilling; As well as the isolation of power supply and water pipelines.

11. Thermal insulation application

Foam concrete contains a large number of closed air holes, the air inside the pores is a good insulation medium and can cut off the heat exchange. The lower its density, the more pores, and the better insulation. In particular, the density of foam concrete is lower than 500㎏/m, and its thermal conductivity is less than 0.09W/M.K. Usually, the thermal conductivity of the material is less than 0.23 called thermal insulation material, the thermal insulation material is less than 0.14 called thermal insulation material. The thermal conductivity of foam concrete is mostly lower than 0.09, so it is a good thermal insulation material.

12. Thermal insulation application

Building thermal insulation is the main application field of foam concrete, accounting for 80% of the total output of foamed concrete for building thermal insulation. Its good thermal insulation performance and building energy-saving policy pull, promote it in the field of building thermal insulation began to large-scale application. The focus of development and application has begun to shift to the wall, the next round of application upsurge will be mainly self-insulation wall. All kinds of foam blocks, foam wallboard, foam cast-in-place wall, and various composite structure exterior wall insulation board have been launched in various places, and their large-scale production and application have begun.

If all building insulation use foam concrete, including roofing insulation thermal insulation layer, wall insulation, thermal insulation layer of floor heating (or bed), equal with foam concrete to wrap the whole room, and a square meters building area is about 0.2 m to 0.5 m foam concrete (roof, floor, the walls are calculated by 5 cm thermal insulation layer). A building with a building area of 10000 square meters needs foam concrete of 2000m-5000 m.

13. Insulation of piping and thermal equipment

The main products of thermal pipe insulation are prefabricated pipe insulation shells and special-shaped materials, as well as thermal insulation panels.

14. Cold storage insulation

Cold storage insulation is now using foam plastic. Because foam plastics are easy to age and flammable, developed countries are changed to foam concrete pouring or masonry insulation layers. Its main use of overall cast-in-place, roof, wall, ground all-foam concrete cast-in-place, no cold bridge, no gap.

15. Industrial furnace insulation

Its main product is refractory heat preservation brick. In order to reduce energy consumption, large industrial furnaces such as iron and steel factories, glass factories, ceramic factories, non-ferrous metal smelters, and cement calcining kilns need to build a layer of thermal insulation refractory bricks on the outside of refractory bricks. Use bleach bead brick, and alumina foam brick more originally, the price is extremely high. Some countries are starting to replace expensive traditional products with foam concrete firebricks, which cost less than half as much and are very competitive.

16. Sound absorption and sound insulation applications

Open-cell foam concrete is an excellent sound-absorbing material, while closed-cell foamed concrete is an excellent sound insulation material. Both of them have a great market, especially sound-absorbing material, with a better prospect.

Usually, the material with an average sound absorption coefficient greater than 0.2 is called sound absorption material. Its traditional products have two categories: fiber (rock mineral wool board, etc.) and porous (foam plastic and foam glass, etc.). Foam concrete is a new type of porous sound-absorbing material, its average sound absorption coefficient is 0.8~1.4, is a strong sound-absorbing material, and can reach the first or second level standard. Its application in the following aspects has great market and competitive advantages.

17. Outdoor sound absorption materials (road and railway sound absorption barriers)

Foam concrete outdoor sound-absorbing material market is mainly highway and railway on both sides of the sound-absorbing barrier. Nowadays, the main sound absorption barriers used in road are wood scraps cement boards, and foam glass boards. The former absorption coefficient is very low, cannot meet the needs of high-speed railway, and is not beautiful, the latter price is too high. And foamed concrete sound absorption performance is good, can meet any road sound absorption requirements, and the price is very low.

18. Indoor wall sound absorption

Indoor sound absorption ceiling and sound absorption wall. Foam concrete has a great market advantage in-wall sound absorption. Compared with rock mineral wool and other fiber sound absorption board, it does not have the disadvantage of making the whole body itch when cutting and installing, and the strength is good, and the price is low. In the subway wall, it will have a great market, in large shopping malls, station waiting rooms, cinema, conference halls, and other building wall has a great market.

Suppliers of Concrete Additives

TRUNNANO is a reliable foaming agents supplier with over 12-year experience in nano-building energy conservation and nanotechnology development.

If you are looking for high-quality CLC foaming agents, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com)

We accept payment via Credit Card, T/T, West Union, and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea.

(Applications of Foam Cement (2))