Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

In the production process of polycarboxylate superplasticizers, the C4 and C6 processes are usually not interchangeable. The main reason is that different numbers of carbon atoms can lead to significant differences in molecular structure, properties, and activity, thereby affecting the quality and yield of the final product.

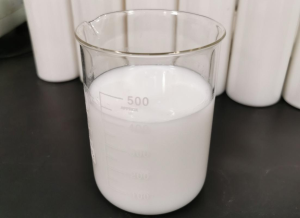

polycarboxylate superplasticizers

The following is a detailed explanation of this issue:

Differences in molecular structure and properties

1. Molecular structure:

C4 polyether: usually synthesized from raw materials such as butanediol or butadiene, with specific molecular chain length and structure.

Carbon Hexapolyether: It is synthesized from raw materials such as hexanediol or hexadiene, with longer molecular chains and different structures.

2. Differences in nature:

Solubility: The solubility of C4 and C6 polyethers in water is different, which affects their dispersibility in water-reducing agents.

Surface activity: Different carbon chain lengths can lead to differences in surface activity, which in turn affect the water-reducing effect of water-reducing agents and the fluidity of concrete.

Stability: The stability of C4 and C6 polyethers varies in different environments, which can affect the long-term performance of the product.

Differences in Aggregation Activity

1. Aggregation activity:

C4 polyether: usually has high polymerization activity and fast reaction rate, but it isn’t easy to control.

Carbon six polyether: relatively low polymerization activity, slow reaction rate, but easier to control.

2. Reaction conditions:

Temperature: The optimal reaction temperature for C4 and C6 polyethers is different and needs to be adjusted according to their respective characteristics.

Catalysts: Different carbon chain lengths may require different catalysts or catalyst concentrations to ensure efficient reaction.

Requirements for equipment and processes

1. Equipment design:

Reactor: The reactor design parameters for C4 and C6 polyethers are different, including stirring speed, heat transfer efficiency, etc.

Separation and purification: Different carbon chain lengths may result in different steps for product separation and purification, requiring targeted process design.

2. Operating conditions:

Temperature and pressure: The reaction temperature and pressure of C4 and C6 polyethers need to be optimized separately to ensure optimal reaction conditions.

Operation steps: Different carbon chain lengths may require different operation steps, such as feeding sequence, reaction time, etc.

In summary, due to the significant differences in molecular structure, properties, and polymerization activity between C4 and C6 polyethers, their production processes and equipment need to be designed and adjusted accordingly. In order to ensure the stability of the production process and the quality of the product, processes with different numbers of carbon atoms cannot be interchangeable. Therefore, in actual production, appropriate process conditions and equipment should be selected based on the specific carbon chain length to achieve the best production effect.

Supplier

Cabr-Concrete is a supplier under TRUNNANO of Concrete Admixture with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for polycarboxylate superplasticizers,please feel free to contact us and send an inquiry.nanotrun@yahoo.com