Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

(Choosing the Best Superplasticizer for Concrete)

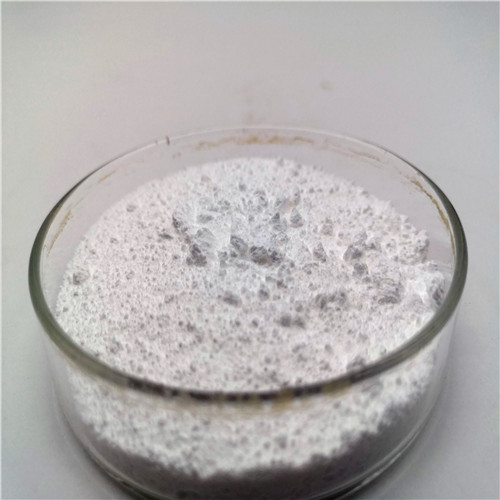

A superplasticizer is a special admixture which combines high range water reducers and plasticizers to improve concrete workability, speed finishing, increase strength, conserve cement, help prevent shrinkage and thermal cracking and reduce odour and biocide. A powerful superplasticizer will transform stiff, low slump concrete into flowing, pourable, easily placed concrete.

Choosing the best superplasticizer for your project is crucial for achieving high quality concrete that performs well on site. The choice must be based on the specific needs of the market, application or area where the concrete is to be produced.

Superplasticizers – chemically different from conventional water reducers

Typical superplasticizers are chemically different to ordinary water reducers and have the ability to reduce water content in concrete mixes by about 30%. These include sulfonated melamine formaldehyde sulphonate (SMF), sulphonated naphthalene sulphonate (SNF), modified lignosulphonates and other chemicals which have similar properties.

They can be used with a variety of cements including blended and sulphate-resisting cements. They are also compatible with mineral admixtures such as fly ash, slag and silica fume.

Reducing capillary porosity and improving workability

Superplasticizers reduce the water-cement ratio by imparting repelling charges to ions in the solution, making it highly workable and flowable even at lower water-cement ratios. This allows for easy placing, good compaction and produces dense concrete with high compressive and flexural strength.

However, these admixtures are subject to degradation by microorganisms so a defoamer is often added. This should be carefully checked to ensure compatibility and avoid problems on site.

(Choosing the Best Superplasticizer for Concrete)