Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

(Compared with the traditional autoclaved aerator process, what are the advantages of CLC aerator equipment? )

CLC aerated block is a kind of aerated concrete block, and its appearance quality, internal pore structure and performance are the same as those of autoclaved aerated concrete block.

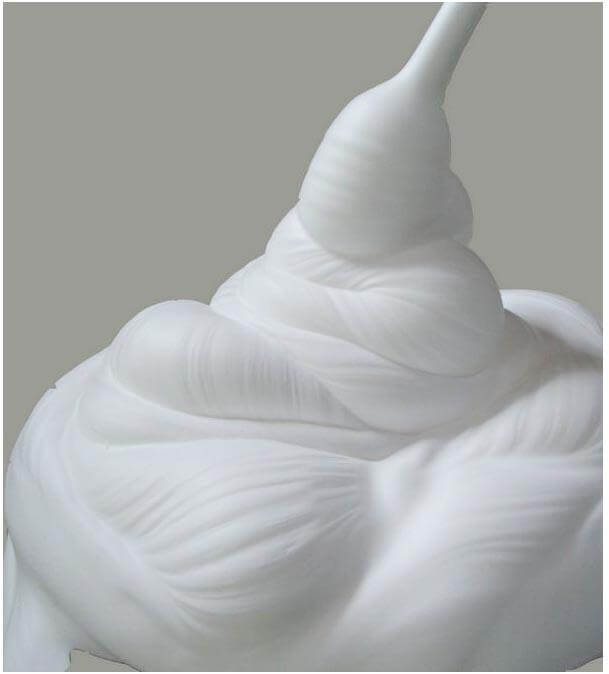

It is a bubble-like thermal insulation material characterized by the formation of closed foam holes in the concrete, making the concrete lightweight and thermal insulation.

The new generation of CLC aerator equipment does not need a high-temperature autoclave. It uses a unique process formula to add gas to the slurry composed of cement and other cementitious materials, fly ash, fillers, water and various admixtures. It is stirred, poured, and naturally cured to form aerated concrete blocks of strength.

High production efficiency: CLC filling block equipment uses an automatic control system, which can be produced continuously, significantly improving production efficiency.

However, the traditional autoclaved aerator process must be operated by hand, and the production efficiency is low.

High energy efficiency: CLC filling block equipment uses advanced energy-saving technologies, such as waste heat recovery, energy reuse, etc., which significantly improve energy efficiency and reduce production costs.

However, the traditional autoclaved aerator process has lower energy efficiency and more waste.

Good product quality: the core part of CLC filling block equipment is the mold and batching system, which can be customized according to different needs to produce different specifications and shapes of filling blocks.

At the same time, due to the use of advanced stirring technology and high-pressure pressing technology, the product density and strength are higher, and the product quality is more stable.

However, the quality of the products produced by the traditional autoclaved aerator process is unstable, and the specifications and shapes are different.

Good environmental performance: CLC aerator equipment adopts environmental protection technology in the production process, such as waste gas treatment, wastewater recovery, etc., which can effectively reduce environmental pollution.

However, the traditional autoclaved aerator process dramatically impacts the environment, and the waste gas and wastewater are challenging to treat.

Good stability of the equipment: CLC aerator equipment uses high-quality materials and advanced production technology, and the stability and durability of the equipment have been greatly improved.

However, the equipment used in the traditional autoclaved aerator process is simple and rough and is prone to failure and damage.

Reduce labor costs: CLC filling block equipment has a high degree of automation, which can reduce manual operation and labor costs.

The traditional autoclaved aerator process requires a lot of manual operation, and the labor cost is high.

Wide range of applications: The production process of CLC filling block equipment is flexible and can be customized according to different market and customer needs.

Therefore, it can be applied to various construction fields, such as housing, commerce, industry, etc.

However, the traditional autoclaved aerator process has a narrow scope of application, and it is generally only suitable for specific construction fields.

Good economic benefits: CLC filling block equipment has the above advantages, can significantly reduce production costs and improve production efficiency, and can also improve product quality and reduce scrap rate.

Therefore, it can improve the economic efficiency and market competitiveness of enterprises.

However, the economic benefit of the traditional autoclaved aerator process is relatively low.

To sum up, the CLC aerator equipment has more advantages and advantages than the traditional autoclaved aerator process.

It can improve production efficiency, reduce costs, improve product quality and environmental protection performance, reduce labor costs, provide a more comprehensive range of applications, provide better economic benefits, and so on.

Therefore, CLC aerator equipment is a more advanced and sustainable construction material production equipment.

Concrete additives Supplier

TRUNNANO is a reliable concrete additives supplier with over 12-year experience in nano-building energy conservation and nanotechnology development.

If you are looking for high-quality concrete additives, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com)

We accept payment via Credit Card, T/T, West Union, and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea.

(Compared with the traditional autoclaved aerator process, what are the advantages of CLC aerator equipment? )