Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

(Early Strength Concrete Admixtures)

early strength concrete admixtures

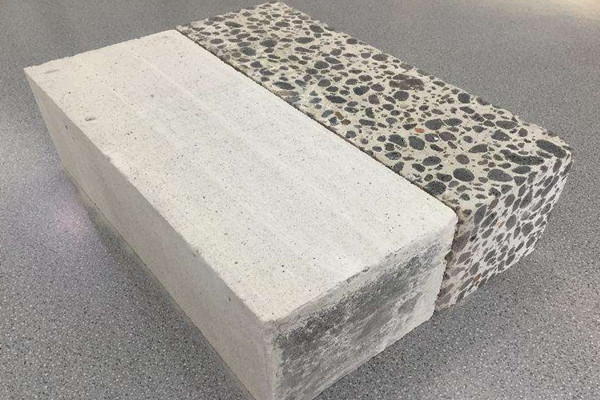

Whether used for rapid form reuse, precast concrete for fast production of elements, high-speed cast-in-place construction, cold-weather construction, quick repair of pavements to reduce traffic downtime, or fast-track paving, concrete admixtures can help you save time and money while also improving the quality of your project. These concrete admixtures can also lower CO2 emissions and energy usage per volume of concrete produced by reducing the water-cement ratio.

Water-Reducing Admixtures

Low-range water-reducing admixtures are commonly used to obtain specific concrete strengths by creating a desired slump at a lower water-cement ratio than what is normally designed for. These admixtures can be used to produce concrete that is more durable, has significantly higher early compressive and ultimate strengths, and lower energy consumption and CO2 emissions.

Retarding Admixtures

Set retarding admixtures delay the chemical reaction that takes place when concrete starts to set and may eliminate cold joints in the concrete. These admixtures are commonly used in concrete pavement construction to save time, reduce additional costs to place a new concrete batch plant on the job site, and help eliminate cracking from form deflection that can occur when horizontal slabs are placed in sections.

Accelerating Admixtures

Several different types of accelerating admixtures can be added to the concrete to speed up hydration and improve early strength development. Examples include calcium chloride standardized by ASTM D 98, ground granulated blast furnace slag, and supplementary cementitious material.

(Early Strength Concrete Admixtures)