Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

(Foam concrete VS. lightweight aggregate )

Although both foam concrete and lightweight aggregate concrete are lightweight, they are very different in manufacturing technology, material composition and performance. This article will briefly introduce the two kinds of concrete.

Lightweight aggregate concrete

Lightweight aggregate concrete refers to concrete that uses lightweight aggregates with an apparent density not exceeding 1950kg/m3. The so-called lightweight aggregate is an aggregate used to reduce the quality of concrete and improve thermal performance, with a lower apparent density than ordinary aggregate. Artificial lightweight aggregate is also known as ceramsite.

Characteristic:Lightweight aggregate concrete has the characteristics of lightweight, high-strength, thermal insulation, fire resistance, and seismic resistance, and has good deformation performance, low elastic modulus, and generally has significant shrinkage and creep.

Applying: Lightweight aggregate concrete is applied in industrial and civil buildings and other engineering projects, which can reduce structural self-weight, save material consumption, improve component transportation and lifting efficiency, reduce foundation load, and improve building functions. It is suitable for high-rise and large-span buildings.

Types of lightweight aggregate concrete

1. According to usage

Lightweight aggregate concrete can be divided into thermal insulation lightweight aggregate concrete, structural thermal insulation lightweight aggregate concrete, and structural lightweight aggregate concrete according to their different uses in construction engineering. In addition, lightweight aggregate concrete can also be used as heat-resistant concrete to replace kiln lining. A block of concrete with a dry apparent density not exceeding 1950kg/m3 is prepared by using natural porous lightweight aggregate or artificial ceramic particles as coarse aggregate, natural sand or lightweight sand as fine aggregate, and Portland cement, water, and admixtures (or without admixtures) according to the mix requirements.

2. According to aggregate

Lightweight aggregate concrete is divided into entirely lightweight concrete and sand lightweight concrete according to the different types of fine aggregates. The use of light sand as fine aggregate is called fully lightweight concrete; Sand lightweight concrete is made of ordinary sand or some light sand as fine aggregate.

Foam concrete, also known as lightweight porous concrete (LCC), low-density porous concrete (LDCC), and other terms, is defined as cement-based grout, and the foam entrained in plastic mortar is at least 20% (per volume). Since coarse aggregate is not used to produce foam concrete in most cases, the correct term should be called mortar rather than concrete; It can also be called foam cement. The density of foam concrete usually varies from 400 kg/m3 to 1600 kg/m3. Density is usually controlled by replacing all or part of the fine aggregate with foam.

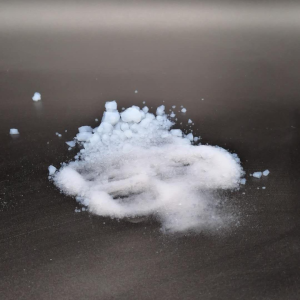

Foam concrete is usually composed of cement slurry or fly ash, sand and water. However, some suppliers recommend mixing water and pure cement with foaming agent to obtain a very light mixture. Furthermore, the slurry is mixed with synthetic aerated foam in the concrete mixing plant. Foam is made by mixing foaming agent with water and air from the generator. The foaming agent must be able to generate highly stable bubbles and resist the physical and chemical processes of mixing, placement, and hardening.

The foam concrete mixture can be poured or pumped into the mold or directly injected into the structural elements. Due to the thixotropic behavior of foam bubbles, foam enables the slurry to flow freely, thus making it easy to pour into the selected form or mold. Adhesive materials can take up to 24 hours to cure (if the steam curing temperature reaches 70 ° C to accelerate the process, it only takes two hours), depending on variables such as ambient temperature and humidity. Once solidified, the formed product can be demolded from the mold. A new application in the manufacture of foam concrete is to use special steel wires to cut large concrete blocks into blocks of different sizes through a cutting machine. The cutting action occurs before the concrete has fully solidified.

The differences between Lightweight aggregate concrete and foam concrete

From the above description, it can be seen that there are obvious differences between foam concrete and lightweight aggregate concrete in manufacturing process, composition and characteristics.

Manufacturing process: Foam concrete is made by adding foaming agent in water to form a large number of bubbles in water and then loading the foamed cement slurry into the mold for static curing. Lightweight aggregate concrete is formed by mixing cement, sand, and water evenly, adding lightweight aggregate and Foamcrete accelerators to form bubbles, and then solidifying in a mold.

Main ingredients: The main ingredients of foam concrete are cement, sand, water and foaming agents. The main components of lightweight aggregate concrete are cement, sand, lightweight aggregate, and Foamcrete accelerators.

Characteristics: Foam concrete has certain advantages, such as good thermal insulation performance, convenient construction, etc., but also has disadvantages, such as low strength, stability problems, etc. Lightweight aggregate concrete has the characteristics of lightweight, high-strength, thermal insulation, and fire resistance and has good deformation performance and low elastic modulus.

Supplier

TRUNNANO is a supplier of CLC concrete with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for high-quality concrete additives, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com).

(Foam concrete VS. lightweight aggregate )