Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

(Foaming principle and its influence on elements of the cement foaming agent in concrete)

The basic concept and purpose of foaming agents

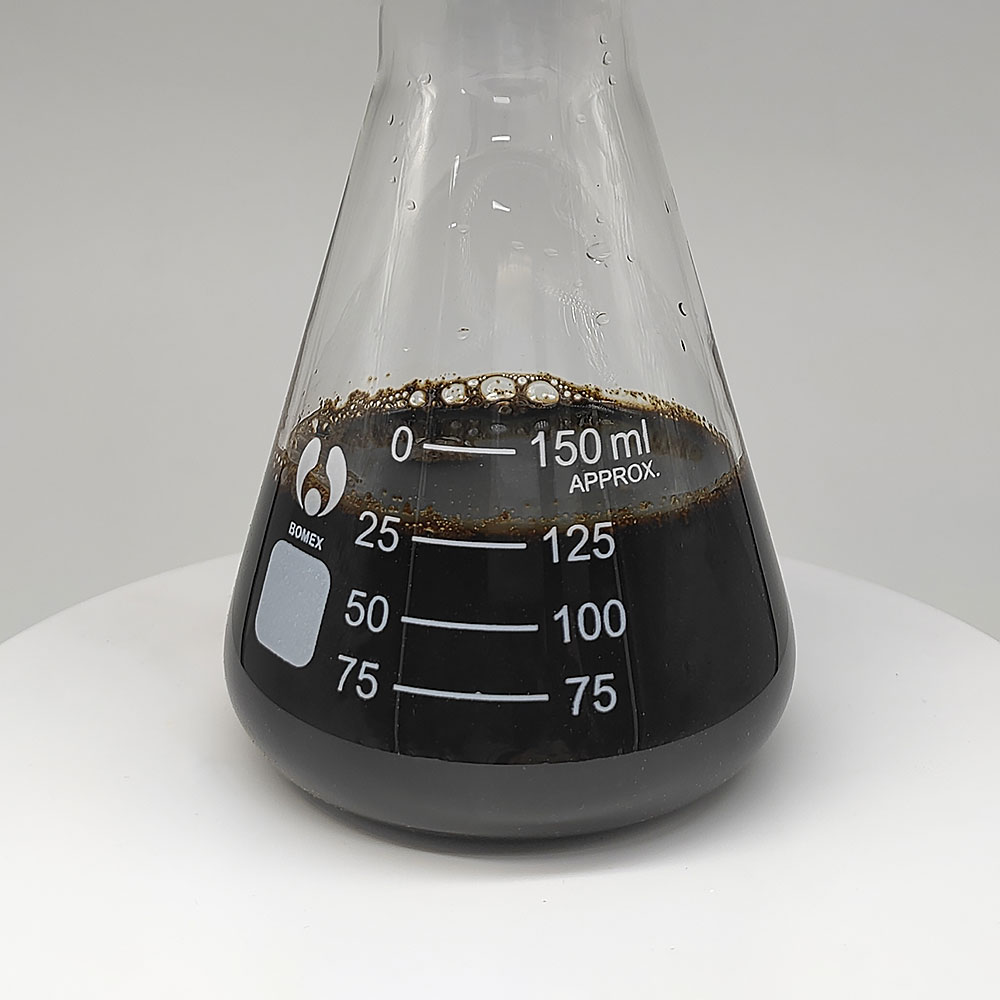

Cement foaming agent is a type of surfactant that contains components such as foam stabilizers, hydrophobic agents, and thickeners. When it mixes with water, these components will interact and produce a large number of bubbles. These bubbles are stabilized by hydrophobic agent, avoiding bubble merging and cracking, and foam also makes cement concrete softer and more porous. At the same time, these bubbles can also improve the permeability, mechanical properties, insulation, sound insulation, and impermeability of concrete.

Firstly, to understand the mechanism of action of cement foaming agents, we need to know their main components and foaming principles. Most cement foaming agents are composed of resins, surfactants, foam stabilizers, etc. When these components are mixed with water, they will produce a large number of bubbles. These bubbles are stabilized by surfactants, thereby avoiding bubble coalescence and rupture.

Secondly, the role of cement foaming agent in foam concrete is mainly reflected in the following aspects: first, improve the pore structure and pore distribution of concrete, improve the permeability and mechanical properties of concrete; The second is to generate bubbles, improving the insulation, sound insulation, impermeability and other properties of concrete; The third is to reduce the density of concrete, thereby reducing the quality and cost of concrete; The fourth is to improve the pumpability and plasticity of concrete, making it easier to construct.

The factors that influence the principle of cement foaming agents

Chemical composition

The chemical composition of cement foaming agent directly affects its foaming effect. The combination and proportion of different ingredients can affect the size, stability, and quantity of bubbles.

Mixing speed and time

Mixing speed and time are also factors that affect the foaming effect of cement foaming agents. If the stirring speed is too fast or the time is too long, it may cause bubble rupture or uneven mixing.

Temperature and humidity

Temperature and humidity can also affect the foaming effect of cement foaming agents. In environments with high temperatures or low humidity, the bubbles generated by foaming agents may be more stable.

Water cement ratio

Water cement ratio refers to the ratio of water to cement and is also an important factor affecting the foaming effect of cement foaming agents. The higher the water cement ratio,i.e., the larger the water ratio, the more bubbles will be generated, but the stability of the bubbles will decrease.

Cement type

Different types of cement have different compatibility with cement foaming agents, which can also affect the final foaming effect.

Therefore, in order to obtain the best foaming effect, it is necessary to select appropriate foaming agent formula and raw materials, and strictly control the mixing, temperature, humidity, water cement ratio and other parameters to ensure the quality of the final foam concrete.

Influence of Cement Foaming Agent on Foamed Concrete

From the above description, we could understand that the influence of cement foaming agent on the quality of foamed concrete is extremely critical. A good cement foaming agent can make high-quality foamed concrete. Take Trunnano TR-C polymer foaming agent as an example. The foam produced by the foaming agent has good stability, can be constructed in a low temperature environment, and the one-time pouring height is more than twice that of similar cement foaming agents. Let's talk about how each performance index of cement foaming agent affects the quality of foam concrete.

The more uniform the foam, the better; the bubble diameter should be the same size

The ideal pore size distribution is as narrow as possible, that is, the pore diameters are required to be as consistent as possible, and the difference should not be too large. This corresponds to the requirement that the foam should be uniform and not of different sizes. The bubble diameter of the foam cannot be exactly the same, but it should be basically similar. The bubble diameter range is as small as possible, and the difference between the maximum bubble diameter and the minimum bubble diameter should not be too large. As mentioned earlier, the pores formed by the foam are required to be uniform, which can avoid the concentration of compressive stress at the large cells and reduce the compressive strength. If the size of the foam is uneven, the stress is concentrated in the big bubble, which is very easy to cause it to become a weak link, which is the first to crack when under pressure.

The higher the foam stability, the better; the longer the stabilization time, the better

The foam with good stability has tough liquid film and good mechanical strength, and it is not easy to burst or excessively deform under the squeeze of the slurry. In addition, it has self-retaining water, and the water on the liquid film is not easy to lose under the action of gravity and surface tension. It can maintain the thickness and integrity of the foam liquid film for a long time. So that the foam can be stored for a long time without breaking. Foam stability can be measured by stabilization time when there is no standard testing instrument to determine its sinking distance. The foam stabilization time should meet the needs of the initial setting of the gelling material used. Because the slurry can fix the foam after the initial setting, retain the shape of the foam, and turn it into pores.

Supplier

TRUNNANO is a supplier of concrete foam agents with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for high-quality concrete additives, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com).

(Foaming principle and its influence on elements of the cement foaming agent in concrete)