Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

(How to choose foam concrete foaming agent)

What caused the bubble to burst?

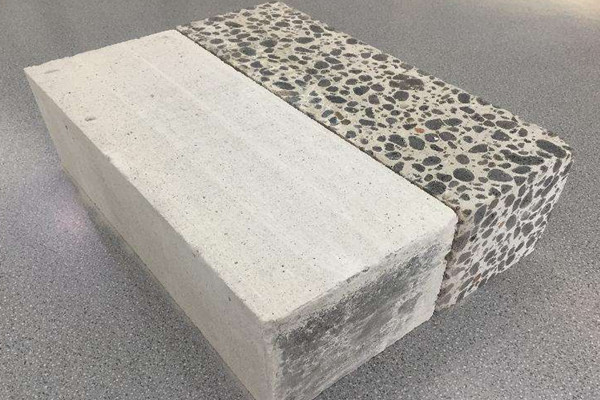

The more uniform and delicate the foam of the foamed concrete foaming agent is, the lower the foam breaking rate, the better. Because of the foaming, the breaking of the foam means cracking, collapse, and the breaking of the foam directly causes the internal structure of the foam concrete to be uneven and compact. The small dark channel formed after the bubble breakage makes the force uneven and seriously affects the strength. Like several piers supporting a bridge evenly, if one, two, three, or four are broken, the force will be uneven, and the strength will be reduced. Bubble channeling and bubble breaking led to decreased strength and increased water absorption. Blistering, the internal structure of the foamed concrete after breaking the foam, forms various dark channels, which cause the water to penetrate the center rapidly, resulting in waterproof failure. Therefore, the problem of bleeding is solved, and the breaking of the foam can greatly solve the water absorption rate. At the same time, waterproof materials are added. The foaming agent can completely solve the problem of water absorption.

What is the water ratio?

The water conversion rate is also a professional reflection of the quality of the foam concrete foaming agent. The concentration of foamed concrete foaming agents is not measured by the standard of water mixing but by the amount of foaming. For example, the conventional foaming amount of 0.4 kg of foaming agent and 6 kg of water is one cubic. Some foaming agents are mixed with 0.4 to 0.8 kg of water and 16 to 80 kg of water, and the foaming amount is also one cubic. Therefore, it is either a foaming agent with a high concentration or a good foaming agent, and the foaming amount is large and stable. Delicate, tough and independent, moderate water mixing, energy-saving, and easy to operate. And the scientific ratio of water mixing makes the water-cement ratio of foamed cement more reasonable, reducing the many capillary pores caused by water evaporation and reducing the cement strength. Therefore, mixing water with scientific proportions is the best. Take a cubic foamed cement as an example: when the cement slurry that has been mixed is mixed with foam, some foaming agents add 6 kg of water, and some additional water ranging from 16 to 80 kg, and the excess water Evaporation causes a large number of capillary pores in the cement, which directly affects the strength of foamed cement. It can be seen that the water-cement ratio increases due to the foaming agent that is mixed with water. To form strong, the proportion of water required. The larger the water-cement ratio, the more water, the more water evaporated during the cement solidification process, and the more capillary pores left by the internal structure of the cement due to the evaporation of water.) On the contrary, it affects the foamed cement. Strength of.

Operational safety and environmental protection, as basic measures, can also be used to judge the quality of the blowing agent. The good quality foaming agent is light, fragrant, non-toxic, safe, causes no harm to workers' skin contact, and has a stable shelf life of more than three years. The perishable and odorous foaming agent has an unstable shelf life and, at the same time, has different degrees of skin damage to the construction workers.

The amount of foaming that affects the foaming agent also has a certain relationship with the foaming machine. Among them, the configuration of steel balls in the foaming machine is a great factor. The foaming agent blows foam, just like a child blowing bubbles. The strength of the blowing force and the circle of the blowing tool has a great influence. The number of steel balls in the foaming machine, the distance, the elasticity, and the strength of the wind directly affect the amount of foaming. Therefore, if the machine is adjusted to a proper operation, the foaming power of the foaming agent will be multiplied by half the effort. For example, in the actual operation experiment, when the original 3 steel balls in the foaming machine are increased to 8, the foaming amount is significantly increased by more than 1 time. However, when the number of steel balls increased to 20, the foaming amount was significantly reduced, so the more steel balls, the better, nor the less, the better, but according to the power of the foaming machine and the different foaming agents, adjustment The most suitable number of steel balls. (The steel ball is recommended to be replaced once every 1000 cubic meters of construction, and it is better to choose a steel ball with fine steel wire and high elasticity).

Luoyang Trunnano Tech Co., Ltd (TRUNNANO) is a professional foaming agent supplier with over 12 years experience in nano-building energy conservation and nanotechnology development. We accept payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea.

If you are looking for high quality foaming agent, please feel free to contact us and send an inquiry.

(How to choose foam concrete foaming agent)