Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

(How to choose the right concrete release agent)

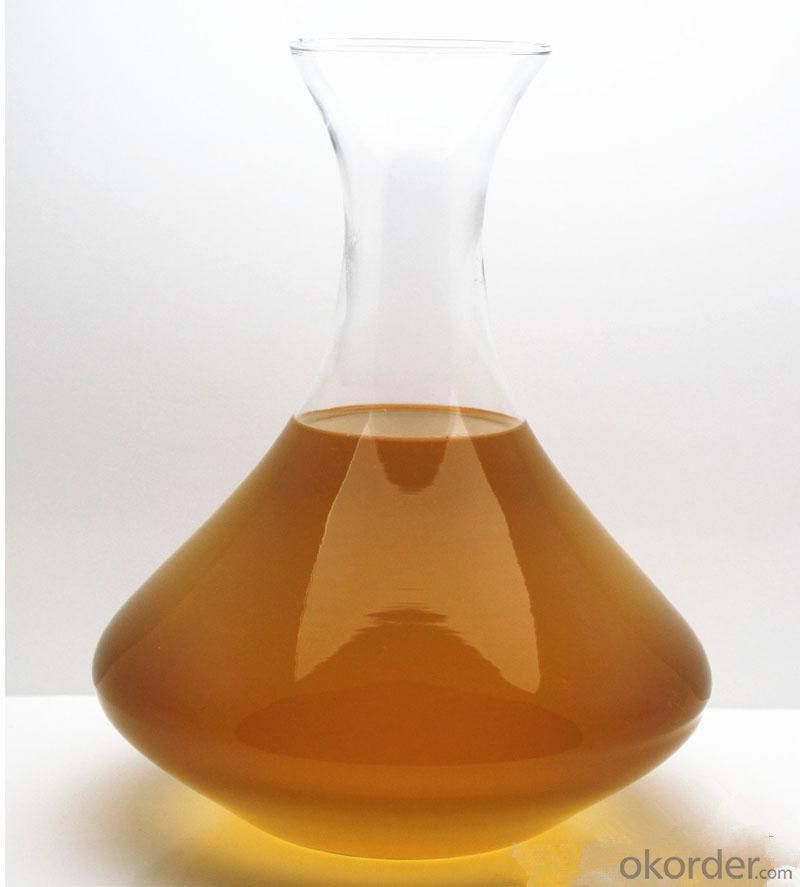

Features of concrete release agent

The paint film is hard, bright and full, water-resistant and wear-resistant, rust-proof and anti-corrosion, especially suitable for projects with strict requirements on the protection of formwork and the quality of concrete appearance. Comprehensive benefits are good. Its characteristics are:

1. Protect the template and prolong the service life of the template. The paint has excellent anti-corrosion and anti-rust functions, which can ensure that the template can be placed outdoors or in rainy days without rusting.

2. It is conducive to improving the appearance quality of concrete, showing the "true color" of concrete, and achieving the effect of "clear-faced concrete". The molded concrete is imitating marble, smooth, uniform in color, delicate in hand, shiny and pollution-free.

3. The surface finish of the paint film is good, and the enamel is naturally formed, which is easy to remove and clean up, and improves the work efficiency.

4. Wear-resistant, good adhesion, can be reused many times.

5. Wide application, can be used for steel mold, wood mold, bamboo mold, etc.

6. The construction is simple, just paint one coat.

Dosage: 15~20 square meters/kg, one brushing can demould 3~5 times.

How to choose concrete release agent?

Concrete release agent is also called concrete release lubricant. It is a substance that is applied to the inner wall of the formwork to lubricate and isolate, so that the concrete can be smoothly separated from the formwork when the formwork is removed, and the shape of the concrete is kept intact. Compared with the traditional mold release material engine oil or waste engine oil, the mold release agent has the advantages of easy mold release, no pollution to the concrete surface, no corrosion of the formwork, easy painting and low price. However, not all types of concrete release agents are suitable for formwork made of various materials. For formwork of different materials and concrete with different construction conditions and finishing requirements, suitable release agents must be selected to receive good results. The selection of mold release agents and related application technical issues are introduced as follows:

Basic requirements for using concrete release agents

The purpose of applying release agent on the inner surface of the concrete formwork is to reduce the bonding force between the concrete and the formwork so that it can be easily separated, so as not to be damaged during demoulding due to the low initial strength of the concrete, keep the surface of the concrete smooth and at the same time protect the formwork , to prevent its deformation or corrosion, facilitate cleaning and reduce repair costs, for this reason, the release agent must meet the following requirements:

1. Good demoulding performance

When removing the formwork, the release agent is required to make the formwork smoothly separate from the concrete, keep the concrete surface smooth and flat, and the edges and corners are neat and undamaged.

2. Easy to coat, quick to mold, easy to clean after mold removal

The release agent can be brushed and sprayed as well, and the mold should be removed quickly (usually within 20 minutes).

It is easy to remove after the mold, so as not to influence the construction progress and product productivity.

3. It does not affect the decorative effect of the concrete surface, and the concrete surface does not leave dipping marks, anti-yellowing and discoloration

4. No pollution to steel bars, harmless to concrete

It does not affect the cohesion between concrete and steel bars, does not change the setting time of the concrete mixture, and should not contain substances that are harmful to the performance of concrete.

5. Protect the template and prolong the service life of the template

The mold release agent for wood mold should be able to penetrate into the surface of the wood mold, play the role of maintenance and caulking of the formwork, and prevent the formwork from expanding, bulging, cracking and defects due to the variation of wood and corners after repeated use of the formwork.

The release agent for steel molds should have the effect of preventing the corrosion of the steel molds and the resulting rust spots on the concrete surface.

6. Has good stability

The concrete release agent should have better stability and longer storage period.

7. Has good water resistance and weather resistance

The release agent used in on-site construction and open-air prefabrication must have a certain resistance to rain erosion, that is, after the release agent brushed on the formwork is exposed to rain, it must be able to maintain the release performance; for thermally cured concrete components, the release agent used The mold agent should be heat resistant; the mold release agent used in cold climates should be frost resistant.

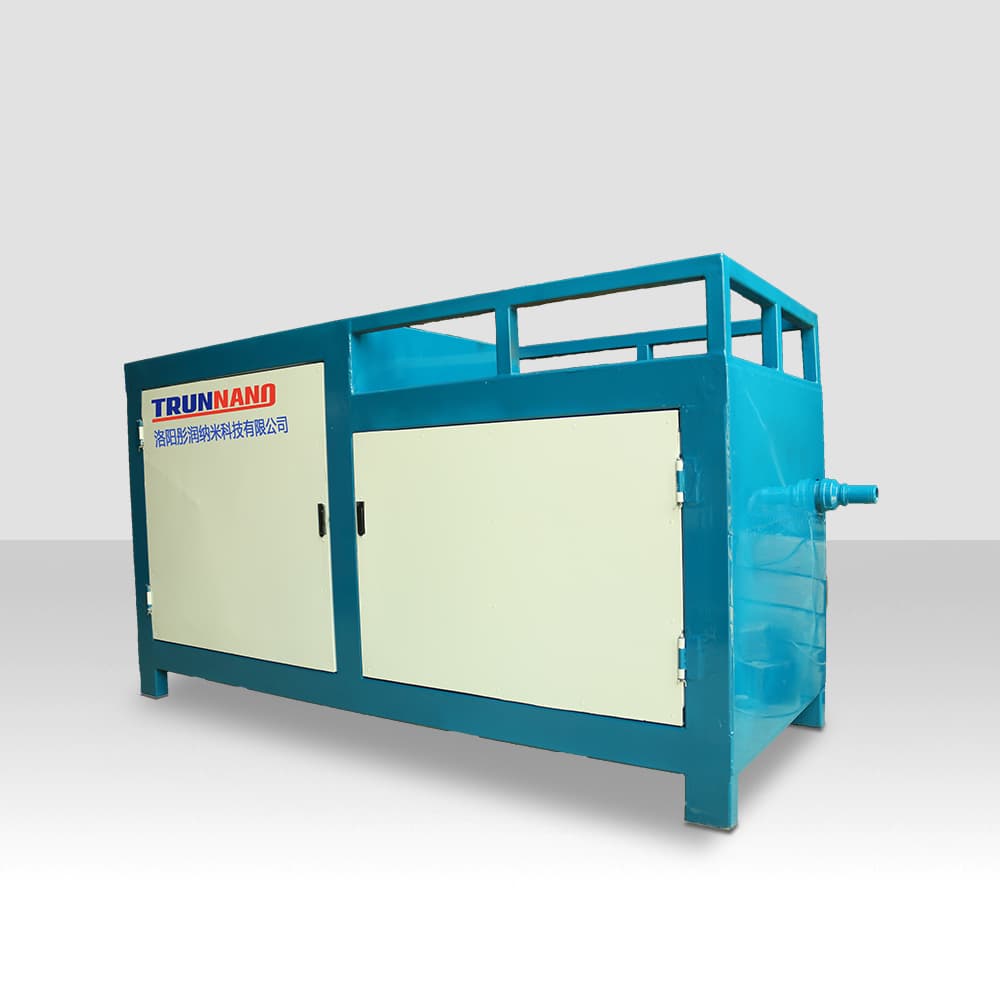

Supplier

TRUNNANO is a supplier of release agent of concrete and other additives, which is concrete and relative products with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for high-quality release agent of concrete and other additives, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com).

(How to choose the right concrete release agent)