Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

(How well do you know about cement foaming machine?)

Cement foaming machine is an important equipment for preparing building materials, which is widely used in fields such as construction, insulation, and waterproofing. Its emergence has brought many conveniences to fields such as architecture, insulation, and waterproofing.

The concept, background, and origins of the cement foaming machine

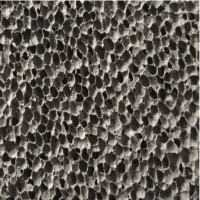

Cement foaming machine is a kind of mechanical equipment used to prepare foaming cement. It can mix foaming agents, cement and other raw materials and prepare the mixed liquid into foam through the special mechanism of the foaming machine. These foam-like materials can be used for thermal insulation and sound insulation of buildings, and can also be used in waterproof engineering.

So, where did the cement foaming machine come from? The origin of cement foaming machines can be traced back to the early 20th century. At that time, some scientists and engineers began to study how to use cement and foam agents to prepare a new type of building materials. They found that adding foaming agents to cement can produce a lightweight, insulated, and soundproof building material. This material not only has excellent physical properties but also has good environmental performance, so it has been widely used.

On this basis, cement foaming machines were gradually developed. The initial cement foaming machine was relatively simple and could only produce relatively single foaming cement. However, with the continuous development of technology, the performance of cement foaming machines has also been continuously improved, allowing for the preparation of more complex and refined foaming cement. At the same time, with the continuous improvement of material performance requirements in the construction and engineering fields, the application range of cement foaming machines is also becoming more and more widespread.

The fundamental principle and use of cement foaming machine

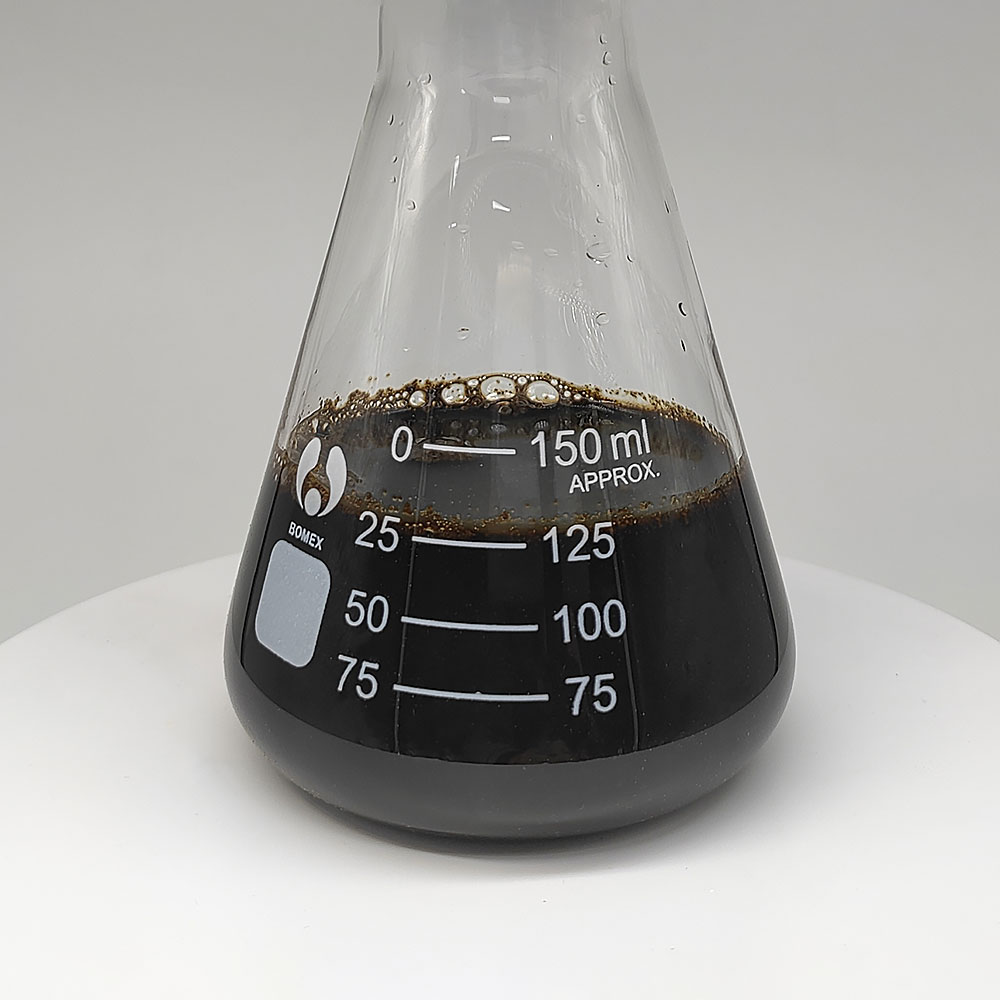

The working principle of the cement foaming machine is not difficult, but it requires a certain amount of technical knowledge and experience to be used correctly. Firstly, the foaming agent and water are mixed in a certain proportion and then fed into the foaming machine together with raw materials such as cement. Inside the foaming machine, these raw materials are thoroughly stirred and mixed before entering the foaming machine. A foaming machine is a closed container with a certain amount of air inside. When the mixed liquid enters the foaming device, the air is rapidly compressed to form foam. These foams are transported to buildings that need insulation or waterproofing.

The correct use of cement foaming machine requires attention to the following points. Firstly, it is necessary to ensure the cleanliness and maintenance of the equipment. Before each use, the equipment needs to be thoroughly cleaned, especially the mixer and pipeline, to avoid the influence of blockage or residue on the prepared foam cement. Secondly, for different engineering projects, it is necessary to adjust the material ratio and proportion to achieve the best performance and effect. In addition, operators need to possess certain technical knowledge and experience to understand the performance and usage methods of various raw materials.

The process flow of cement foaming machine includes steps such as batching, mixing, foaming, and ripening. Ingredient refers to the preparation of various raw materials in a certain proportion. Mixing refers to the full mixing and mixing of these raw materials. Foaming refers to the sending of the mixture into the foaming device to form foam. Curing refers to the natural drying and solidification of the foam-like mixture.

The application effects of cement foaming machines vary greatly in various industries. In the field of building insulation, foamed cement prepared by cement foaming mechanism has good insulation and sound insulation effects, which can improve the comfort and energy-saving effect of buildings. In the field of waterproofing engineering, foamed cement prepared by cement foaming mechanism has good waterproofing performance and durability, which can effectively protect buildings from moisture damage.

The performance and the influencing factors of the cement foaming machine

The performance and function of cement foaming machines have a crucial impact on the quality and efficiency of the final product. When evaluating the performance of cement foaming machines, analysis can be conducted from different perspectives. Firstly, production capacity is one of the important indicators for evaluating the performance of cement foaming machines, including the volume of foaming cement that can be prepared per unit time, the stability and controllability of foaming, etc. Secondly, bubble stability is also a key factor in evaluating the performance of cement foaming machines, which directly affects the quality and performance of the final product. In addition, mechanical reliability is also one of the important factors in evaluating the performance of cement foaming machines, including equipment reliability, stability, and durability.

Many factors affect the performance of cement foaming machines, among which equipment parameters, process parameters, and environmental temperature are the main factors. The parameters of the equipment itself include the design, structure, materials, and dimensions of the equipment, which can directly affect the performance and production capacity of the cement foaming machine. The process parameters include the type and concentration of foaming agent, cement type and concentration, mixing speed and mixing time, etc. These parameters can affect the stability and quality of the final product's bubbles. Environmental temperature is also one of the important factors affecting the performance of cement foaming machines, which can directly affect the curing speed of products and the quality of the final product.

Based on the performance evaluation and analysis of influencing factors above, the following optimization strategies for cement foaming machines can be proposed. Firstly, when selecting equipment, factors such as equipment design, structure, and materials should be considered, and equipment with high reliability and good stability should be selected. Secondly, the quality and efficiency of products can be improved by improving process parameters, such as adjusting the type and concentration of foaming agents, cement type and concentration, mixing speed, and mixing time. In addition, the method of increasing the operating temperature can be adopted to accelerate the curing speed of the product, thereby improving production efficiency.

Supplier

TRUNNANO is a supplier of cement foaming machine and foam agent with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for high-quality concrete additives, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com).

(How well do you know about cement foaming machine?)