Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

Hydrofluoric acid is an aqueous solution of hydrogen fluoride (HF), which is a binary compound composed of one hydrogen atom and one fluorine atom. It has several unique features that make it different from other acids:

High reactivity: HF has high reactivity, especially with metals, glass, and ceramics. This reactivity is due to the small size and high electronegativity of fluorine atoms, which makes HF an excellent etchant for silicon and silicon dioxide surfaces.

Corrosivity: Due to its ability to dissolve silicon dioxide (SiO2), hydrofluoric acid can corrode glass and many metal oxides, making it particularly suitable for applications that require precise material removal or surface modification.

Toxicity: HF is extremely toxic, especially in concentrated form. Even a small amount of contact can cause severe burns and systemic poisoning, and strict safety regulations are required during handling and storage.

The molecular structure of HF enables it to form strong hydrogen bonds, which contribute to its low boiling point (-83.6 ° C) and high solubility in water. These characteristics are crucial for their effectiveness in various industrial processes.

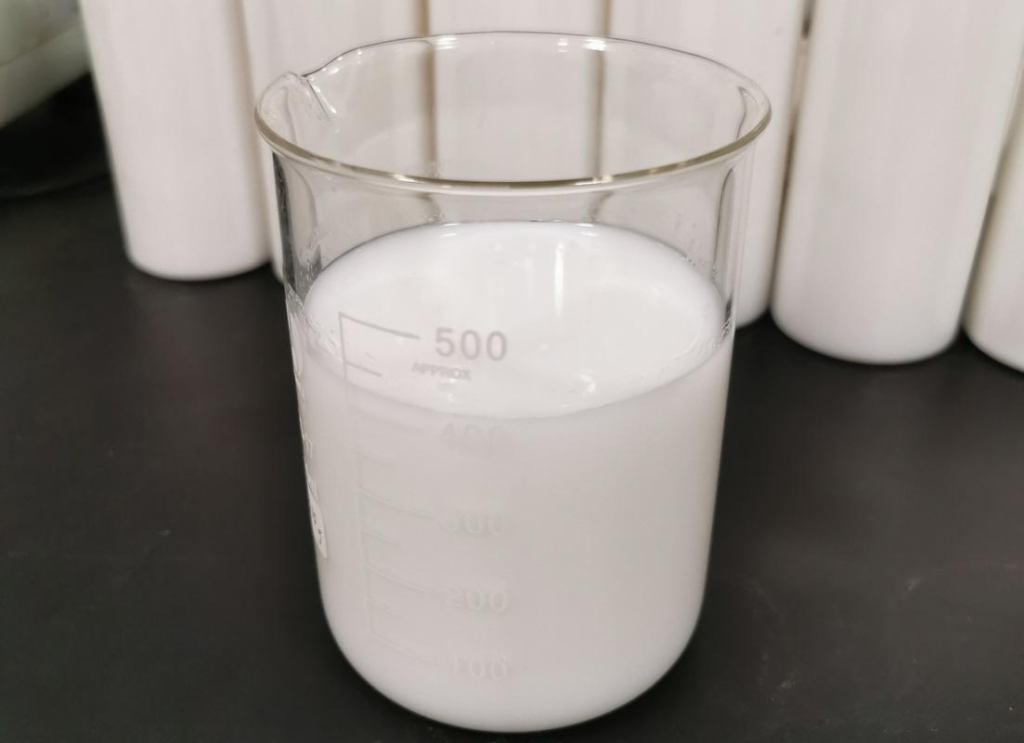

Hydrofluoric acid accelerator

Industrial application of hydrofluoric acid

Semiconductor manufacturing: In the electronics industry, HF is used to clean and etch silicon wafers, removing oxide layers without damaging the underlying silicon substrate. This precision etching is crucial for producing high-performance microchips and integrated circuits.

Fluoropolymer production: Hydrofluoric acid is a key raw material for synthesizing fluoropolymers such as polytetrafluoroethylene (PTFE) (commonly known as Teflon). These polymers have excellent heat resistance, chemical resistance, and friction resistance, making them invaluable in various applications.

Aluminum refining: HF is used to purify aluminum fluoride, which is an important component in aluminum electrolytic refining. Acid helps to remove impurities and ensure the production of high-purity aluminum.

Petroleum industry: Hydrofluoric acid is used in the alkylation process of refineries to produce high-octane gasoline components. Its catalytic performance has improved the efficiency of these reactions.

Application of Hydrofluoric Acid in Accelerator Production

In special applications, hydrofluoric acid is used to produce certain accelerators, especially those designed for rapid solidification of concrete. The reactivity of hydrofluoric acid can enhance the performance of these additives by promoting faster hydration reactions and improving early strength development.However, a major challenge emerged during the production process: high temperature. When manufacturing hydrofluoric acid-based accelerators, the reaction temperature may become quite high. This has raised concerns about worker safety and the environment, especially the release of toxic gases.

Addressing the issue of toxic air emissions in high-temperature hydrofluoric acid processes

Producing hydrofluoric acid based accelerators at high temperatures does indeed result in toxic air emissions. If not managed properly, hydrogen fluoride gas and other volatile compounds may escape into the atmosphere. Inhaling these fumes can cause severe respiratory irritation, lung damage, and systemic toxicity, posing serious health risks to workers and nearby communities. To mitigate these risks, several strategies can be implemented:

Process optimization: Engineers can optimize production processes to minimize peak temperatures and reduce the formation of volatile byproducts. Adjusting reaction conditions such as pH and catalyst concentration can help achieve this goal.

Ventilation system: Installing advanced ventilation systems with scrubbers and filters can capture and neutralize harmful emissions before they are released into the environment. Scrubber technology, including wet and dry scrubbers, can effectively remove hydrogen fluoride and other pollutants from exhaust gas.

Control measures: It is crucial to ensure proper control of hydrofluoric acid and its derivatives throughout the entire production process. Sealed reactors, pressure control systems, and automatic transmission mechanisms can prevent leakage and overflow.

Monitoring and detection: A continuous monitoring system equipped with hydrogen fluoride detectors can provide real-time data on air quality. Timely detection can take immediate corrective measures and improve worker safety.

Personal protective equipment (PPE): Provide PPE specifically designed to prevent exposure to hydrofluoric acid, such as full-face respirators and chemical-resistant clothing, to ensure workers remain safe even in high-risk situations.

Case study: Managing toxic emissions in the production of hydrofluoric acid-based accelerators

A noteworthy case study involves a factory specializing in the production of hydrofluoric acid-based accelerators. Initially, the factory experienced high temperatures during the synthesis process, leading to concerns about toxic air emissions. The workers reported discomfort and occasional respiratory problems, prompting management to take action. The engineering team has introduced several improvements, starting with process optimization. By fine-tuning the reaction parameters, they reduced the peak temperature and minimized the formation of volatile compounds to the greatest extent possible. Next, they installed a state-of-the-art ventilation system with multi-stage scrubbers capable of capturing over 99% of hydrogen fluoride emissions.

In addition, the facility has strengthened containment measures to ensure that all reactors and transport pipelines are completely sealed. A continuous monitoring system has been deployed to track air quality in real time and provide immediate alerts for any deviations. The workers also received upgraded personal protective equipment, including full-face respirators and chemical-resistant clothing. These comprehensive measures have significantly improved workplace safety and environmental compliance. The emissions of toxic substances have significantly decreased, and no further incidents of worker discomfort have been reported. The facility’s commitment to safety and sustainability has become a benchmark for similar operations worldwide.

Hydrofluoric acid remains a key component in various industrial applications, with unparalleled performance and versatility. However, its inherent toxicity and reactivity require strict safety protocols and innovative solutions to address potential hazards. With the continuous advancement of research and technology, the future application of hydrofluoric acid is expected to achieve greater innovation and safer practices. Addressing challenges such as toxic air emissions during high-temperature processes will pave the way for more sustainable and resilient industrial operations.

Supplier

Cabr-Concrete is a supplier under TRUNNANO of Concrete Admixture with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for Hydrofluoric acid accelerator, please feel free to contact us and send an inquiry.sales@cabr-concrete.com