Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

(The cooling tower of Willow Island Power Plant in the United States collapsed, killing 51 workers! The reason is that the cement is not dry?)

Looking back at history, power plant cooling tower collapse accidents have occurred numerous times, large and small. The most severe incident was the cooling tower collapse of the Willow Island Power Plant in the United States. Thirty-eight years ago, the worst disaster in construction history occurred in the United States, resulting in the unjust deaths of 51 workers. How did this tragedy happen?

Back in 1978. At the Willow Island Power Plant site, the second cooling tower of the power plant is under construction, and most of the construction workers are busy on the scaffolding. At this time, the concrete workers had already transported the first bucket of concrete to the No. 4 wall-mounted crane. After pouring the concrete into the trolley, the collapse accident began.

A loud shattering sound suddenly came from high in the sky, and at the same time, a lot of concrete fell to the ground. Workers at the center of the cooling tower found that it had dropped from the 28th floor, which was the pouring layer that had only been poured yesterday. They quickly informed the workers on the scaffolding to take measures, but the workers above had no time to react. The second bucket of concrete had already been transported two-thirds of the way to the top, and the suspension cable could not bear the weight and began to loosen.

In a short period, the concrete on the 28th floor of the building had developed from falling off to collapsing and spread in a circular shape. All scaffolding and formwork also collapsed and fell towards the interior of the cooling tower. Workers on the ground were luckier and quickly took shelter under concrete trucks. The 51 workers on the scaffolding had no time to escape and were all buried in the falling wreckage, tragically losing their lives.

The construction project of this power station is vast and has always attracted attention from the outside world. Now that such a tragic safety accident has occurred, it has naturally attracted significant attention from all parties.

People have also discussed the reasons for the collapse of the cooling tower. The most common theory is that corners were cut during the construction of the cooling tower. However, after a detailed investigation, this reason still needs to be established. All materials used in the construction of cooling towers, including construction equipment and building structures, are strictly in accordance with regulations. In this regard, the investigation team is also very puzzled. There are no problems. Could it be that it is really a ghost?

Later, they investigated again and reviewed the investigation process many times, and finally found out the reason. The problem lies in the concrete that needs to dry correctly.

Most people don't know that the construction method of cooling towers is different from that of ordinary buildings. During the construction process of cooling towers, poured reinforced concrete tower walls are usually used as supports, and then operating platforms such as scaffolding, suspension cables, and formwork are built on top. When the concrete poured in the lower layer is fully cured and has sufficient strength, the formwork will be removed and installed on the upper layer, and then the next round of pouring will be carried out. However, when the 28th floor of Willow Island's cooling tower was poured, perhaps due to the low temperature at that time, the construction team asked to remove the formwork the next day before the concrete was arid and solidified. In the end, the pouring layer was not strong enough to bear the weight of the entire operating platform, so it collapsed, leading to this tragedy.

Who would have thought that this small piece of cement would cause the most significant safety accident in the history of American construction? In fact, whether in the construction industry or any other aspect, a seemingly unimportant mistake can cause tragedy. We must learn from every accident to prevent tragedies from happening again.

Concrete not dry? An accelerator could help

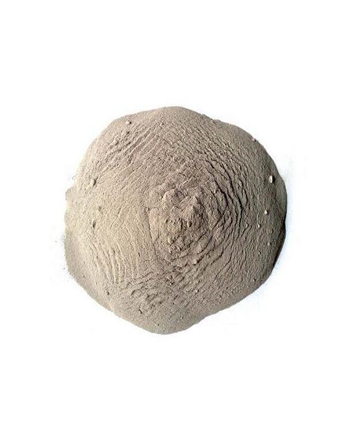

The concrete accelerator is a unique admixture whose primary function is to make fresh concrete set quickly in a short period.

The main uses of accelerating setting agents are: in the construction of tunnels, mines, etc., shotcrete can quickly harden and bond to prevent collapse; in emergency repair projects, accelerating setting agents can be used to repair cracks or holes in the concrete structure without affecting its overall structure. Bearing capacity in military engineering, accelerators can be used to build shelter fortifications quickly.

Supplier

TRUNNANO is a supplier of alkali-free liquid concrete accelerator(which is one of concrete additives) with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for high quality concrete additives, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com).

(The cooling tower of Willow Island Power Plant in the United States collapsed, killing 51 workers! The reason is that the cement is not dry?)