Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

(What are CLC Concrete Advantages?)

CLC Concrete Advantages

Foamed concrete has good physical properties, combining insulation and electrical resistance. It has many benefits that make it one of the best alternatives to building materials. For example:

Rapid assembly

Its low density and lightness allow for increased installation speed. It's also easy to work with because it's not a complex material to cut from.

Compressive strength

It varies with the density of the material. Obviously, the greater the density, the greater the resistance. You can even use it to build multi-level collective housing.

Resistance to water absorption

The concrete structure absorbs water much more slowly. It is a humidity regulator that absorbs any excess humidity or softens dry air. In this way, you can create a pleasant atmosphere in your home.

Thermal insulation

As we mentioned earlier, it maintains a comfortable and cool indoor environment in both winter and summer.

So, during the cold season, the interior will stay warm, and in the summer, we will be able to keep the interior cool. This will save a lot on air conditioning and heating costs.

Economical

Foamed concrete is 10 to 87 percent lighter than conventional concrete. This substantial reduction in weight represents significant savings when building foundations and structures.

Transport

As a light material, it weighs only half as much as similar materials. This makes shipping tasks, as well as working with it (cutting, hammering nails, sawing, etc.) much easier.

Durability

Porous concrete ages well over time. It's as durable as rock and doesn't break down.

Sound absorption

Only a small amount is absorbed by the concrete, and most of it bounces back into place. The noise that actually reaches the interior is minimal.

Versatility

It's a very versatile material when it comes to shape and form. It can be easily made into anything: arches, pyramids, angles, etc. Therefore, it adds to the aesthetic impact of the building.

Fire resistance

Due to its low thermal conductivity, foamed concrete has a very low heat flux. It is an ideal material for industrial, agricultural and administrative buildings.

Reduce waste

This is critical in areas of high seismic risk. If an earthquake occurs, the broken walls will collapse, but not as much as other traditional materials.

CLC Concrete Types

Pure CLC Concrete

Use portland cement, water, and prepared foams or gases. It has no solid aggregates. To make it, water is mixed with cement and then chemicals or foams are added, which must be mixed correctly to achieve cellular consistency.

Sanded CLC Concrete

It contains cement, water, selected foamed aggregate, and sand with a maximum diameter of 4mm.

Lightweight aggregate concrete

It is composed of pumice stone and tezontle instead of sand and stone. These aggregates must have strong compressive properties to increase compressive strength.

Foam concrete with expansive aggregate

The addition of these aggregates has been shown to help retain moisture when curing concrete in hot climates.

It is also a protective element for metal structure fire prevention.

Foam concrete containing dispersant additives

The dispersal effect of the additive helps hydrate the cement particles, improving compression resistance and increasing fluidity due to a reduced cement/water ratio.

Suppliers of Concrete Additives

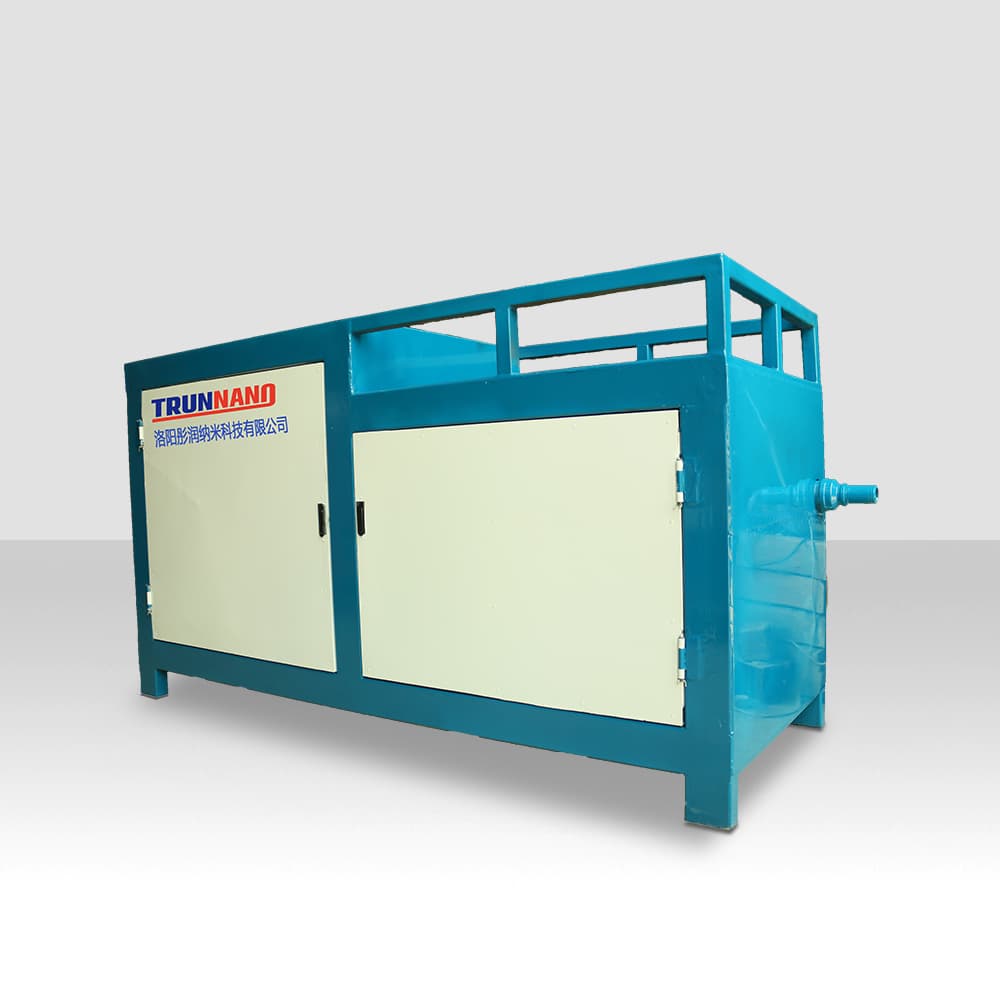

TRUNNANO is a reliable foaming agents supplier with over 12-year experience in nano-building energy conservation and nanotechnology development.

If you are looking for high-quality CLC foaming agents, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com)

We accept payment via Credit Card, T/T, West Union, and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea.

(What are CLC Concrete Advantages?)