Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

(What is LCC Foam Concrete?)

What is Foam Concrete?

Foam concrete, also known as lightweight cellular concrete (LCC), low-density cellular concrete (LDCC), and other terms, is defined as a cement-based slurry with a plastic mortar containing at least 20% foam per volume. Since coarse aggregate is not used in most cases to produce foam concrete, the correct term should be mortar rather than concrete; It can also be called "foam cement". The density of foam concrete usually varies from 400kg/m3 to 1600kg/m3. Density is usually controlled by replacing all or part of the fine aggregate with foam.

Foam Concrete History

The 1930s blacksmith bridge was filled with foam concrete.

The history of foam concrete dates back to the early 1920s when autoclaved aerated concrete was produced primarily for insulation. Detailed studies on the composition, physical properties, and production of foam concrete were first carried out in the 1950s and 1960s. Following this study, new admixtures were developed in the late 1970s and early 1980s, which led to the commercial use of foam concrete in construction projects. Originally, it was used for void filling and ground stabilization in the Netherlands. Further research carried out in the Netherlands has contributed to the wider use of foam concrete as a building material. Recently, continuous foam generators are being used to make foam concrete. Foam is produced by mixing the foaming agent with compressed air to make "aircrete" or "foam create". This material is fireproof, insect-proof, and waterproof. It provides significant heat and sound insulation and can be cut, carved, drilled, and molded using woodworking tools. This building material can be used to make foundations, subfloors, building blocks, walls, domes, and even arches reinforced with fabric.

Foam Concrete Manufacturing

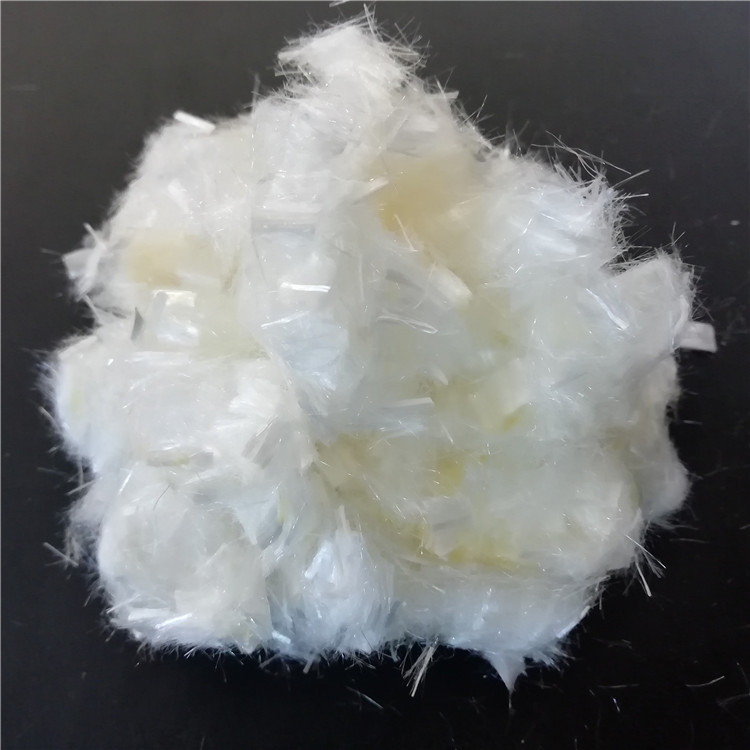

Foam concrete usually consists of cement slurry or fly ash, sand, and water, but some suppliers recommend using pure cement and water as well as foaming agents to make a very lightweight mixture. The slurry is further mixed with synthetic inflatable foam in a concrete mixing plant. The foam is created using a foaming agent, which is mixed with water and air from a generator. The foaming agent must be able to produce highly stable bubbles that are resistant to the physical and chemical processes of mixing, placement, and hardening.

The foam concrete mixture can be poured or pumped into molds or poured directly into structural elements. Due to the thixotropic behavior of foam bubbles, foam enables the slurry to flow freely, making it easy to pour into selected forms or molds. Viscous materials can take up to 24 hours to cure (or as little as 2 hours if the steam curing temperature reaches 70°C to speed up the process. Depends on variables, including ambient temperature and humidity. Once cured, the resulting product can be released from its mold. A new application in the manufacture of foam concrete is to cut large concrete blocks into blocks of different sizes by cutting machines using special steel wires. The cutting action takes place before the concrete has completely cured.

Concrete Foaming Agent Supplier

TRUNNANO is a reliable foaming agents supplier with over 12-year experience in nano-building energy conservation and nanotechnology development.

If you are looking for high-quality CLC foaming agents, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com)

We accept payment via Credit Card, T/T, West Union, and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea.

(What is LCC Foam Concrete?)