Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

(What Raw Materials Affect the Strength of Foam Concrete)

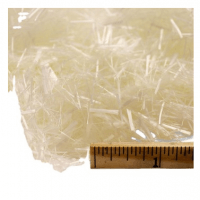

The main components of foam concrete are: cement, foaming agent, aggregate, fly ash, admixture and water. When necessary, other ingredients can be used according to requirements, such as chopped fibers and organic polymers, which all affect the strength of foam concrete.

Cement

For foam concrete, the importance of cement is self-evident. Cement is the main source of strength of foam concrete, which also determines the overall strength of concrete to a large extent. Therefore, in order to achieve maximum strength, there is an optimal cement content value for the dry density of foam concrete. This value exists in an ideal mix ratio, which can ensure that the concrete has sufficient strength without wasting materials.

It is worth noting that different blocks of cement have different effects on the strength of foam concrete due to their different raw materials and production processes. Therefore, the key step to producing high-quality foam concrete is to select the appropriate cement type and determine its dosage.

In the non-paste system, with the increase of cement content, the strength of foam concrete will increase until the optimal cement content is reached. Once this dosage is exceeded, the trend of strength increase will reverse and decrease with a further increase in cement dosage. The occurrence of this phenomenon may be due to the formation of pores inside the concrete due to excessive cement, which affects the overall strength of the concrete.

In the neat cement slurry system, because of the use of full water dilution, the cement consumption is relatively fixed, so in this system, changing the cement strength grade will have a significant impact on the strength of foam concrete. This requires special attention during the production process to prevent the improper selection of cement strength grade from affecting the quality of concrete.

Portland cement series products have stable quality, low price and good durability, so they are widely used in the current foam concrete industry. However, no matter what kind of cement is used, it is very important to know the cement amount and its mix proportion with foam. Only through reasonable proportioning and precise control can we produce high-quality foam concrete products.

Foam Agent

Not all of the materials that can produce foam can be used as suitable foaming agents to prepare foam concrete. In order to ensure the quality and stability of foam concrete, the foaming agent must have some specific properties. Firstly, when mixed with mortar, it must not cause mortar cracking and maintain its stability. Secondly, the addition of foaming agents should not have a negative impact on the performance of bonding and hardening materials.

The density of foam concrete can be adjusted by changing the amount of foaming agent. With the increase in the amount of foaming agent, the density of foam concrete will decrease accordingly, and vice versa. This density change directly affects the strength of foam concrete. After the introduction of foam, the strength of concrete will be reduced due to the existence of a large number of pores. However, foam concrete with high strength and stability can be prepared by optimizing the amount of foaming agents and selecting appropriate raw materials.

In addition, the strength of foam concrete does not depend only on its density. The size, distribution, and stability of foam and the properties of the concrete matrix will also affect its strength. Therefore, when preparing foam concrete, these factors need to be comprehensively considered according to specific needs to obtain the optimal and most efficient preparation process.

Aggregate

The preparation of foam concrete aggregate is generally divided into three categories: ordinary aggregate, light aggregate and ultra-light aggregate. These aggregates play an important role in foam concrete, which can increase the strength, durability and stability of concrete.

Ordinary aggregate is a commonly used type of aggregate with high density and strength. It can improve the overall strength and compressive performance of foam concrete and help to improve the durability and stability of concrete.

Lightweight aggregate is another commonly used type of aggregate, with a lighter density and lower strength. It is mainly used to reduce the density of foam concrete and can also improve the thermal insulation and sound insulation performance of concrete. Light aggregate can make the structure of cement paste more compact, thus improving the overall strength and compressive performance of foam concrete.

Ultralight aggregate is a kind of aggregate with extremely low density and strength, which is usually used to prepare foam concrete with low density, high thermal insulation performance, and high sound insulation performance. Ultralight aggregate can improve many properties of foam concrete, such as heat preservation, sound insulation, compression resistance, and durability.

When preparing foam concrete, different types of aggregates need to be selected according to specific application scenarios and requirements. The strength of foam concrete is significantly affected by different aggregate types and apparent densities. In order to ensure the density and strength of foam concrete, the use of lightweight aggregate can make the structure of cement paste more compact than ordinary aggregate, thus improving the overall performance of foam concrete.

Fly ash

In view of its wide sources, low price, and certain activity, fly ash has become the preferred admixture for foam concrete admixtures. Fly ash can dramatically increase the strength of concrete that has been foamed and increase its forming ability.

Admixtures

The common admixtures used in foam concrete are dispersants and early strength agents, rapid curing agents, water-proofing agents, and water repellent agents. Accelerators and early strength agents are able to accelerate the process of formation and strengthen the foam concrete structures, as well as enhance the durability of the structure of the slurry.

Supplier

TRUNNANO is a supplier of foam agents with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for high-quality concrete additives, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com).

(What Raw Materials Affect the Strength of Foam Concrete)