Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

(What should be paid attention to in the safety production of foam generator?)

As an important construction equipment, the safe use of concrete foaming machines is crucial for ensuring construction quality and worker safety. When operating this type of equipment, it is necessary to pay attention to some key safety precautions to ensure efficiency and safety. The following are the safe usage methods for concrete foaming machines.

1、 Preparation before operation

Before operating the concrete foaming machine, as a staff member, it is necessary to take safety precautions first. This includes wearing work clothes, hats, and suitable shoes, as well as wearing protective glasses. In addition, to ensure good ventilation conditions, it is necessary to place the work site in a well ventilated area and maintain cleanliness and hygiene at the workplace.

2、 Pay attention to temperature changes

During operation, especially in high temperature environments, it is necessary to pay attention to changes in ambient temperature. When the ambient temperature is too high, the concrete foaming machine may exhibit unpredictable behavior, thereby increasing the risk of use. Therefore, if the ambient temperature is too high, it is advisable to avoid using a concrete foaming machine as much as possible or ensure that the equipment has been fully cooled before use.

3、 Keep equipment clean

The cleanliness of concrete foaming machines has a significant impact on their effectiveness. If there are impurities inside or outside the equipment, such as dust, mud, etc., It could interfere with it's normal functioning of device or even cause malfunction or damage. Therefore, the equipment should be kept clean before and after operation.

4、 Adding flame retardants

During the production process, a certain proportion of flame retardants need to be added to the concrete foaming machine. The addition ratio can usually be maintained at 10% -15%. When adding flame retardants, operators need to wear corresponding protective equipment, such as protective gloves, protective glasses, etc., to prevent possible chemical harm. At the same time, it is necessary to ensure uniform mixing during the addition process to ensure that the flame retardant can be fully integrated into the concrete.

5、 Precautions during operation

Check the safety valve of the cement foaming machine, hydraulic system steel pipes and hoses, connections, and oil cylinders, and find any wear and cracks. Check the pipeline from the safety valve to the inlet of the oil cylinder to ensure that there is no diarrhea or caused by impact and wear. The deformation ensures the completeness and complete fastening of the connecting piece.

Inspection and treatment of leaking parts of cement foaming machine. The main leak detection parts are: liquid level gauge, oil drain plug, oil pump, oil motor shaft and shell joint surface, oil cylinder head joint surface, oil cylinder piston rod extension, hydraulic valve joint surface, adjustment handle extension Parts, oil pipe joints, oil cylinders.

The lubricating grease of the cement foaming machine must be sufficient and clean at all times, and the lubrication pipeline joints must not leak. Check the lubrication of each operating part at any time. If there is a part lacking oil, stop the machine for inspection immediately to prevent accidents.

During the operation process, attention should be kept focused and distractions or other unrelated tasks should be avoided. At the same time, it is necessary to always pay attention to changes in the surrounding environment to prevent potential hazards from occurring. Secondly, it is necessary to avoid excessive twisting or compression of the equipment to prevent equipment damage or personal injury. Do not operate the concrete foaming machine without receiving professional training. For personnel who are not familiar with the operation process, it is necessary to operate under the guidance of professional personnel. If encountering any problems or difficulties, immediately stop the operation and seek professional assistance. Do not attempt to solve it on your own to avoid causing greater loss or injury.

During use, staff should regularly inspect and maintain the various functions of the equipment to ensure its normal operation. If any abnormalities or malfunctions are found, immediately stop using them and contact professional personnel for repair.

6、 Maintenance after operation

After the operation is completed, a comprehensive inspection and cleaning of the equipment should be carried out. This includes cleaning up residues and debris inside the equipment, checking for damage or wear on various components, etc. If the equipment is not in use for a long time, regular maintenance should be carried out. This includes replacing lubricating oil, inspecting fasteners, etc. While at the same time the charging device or battery must be checked on a regular basis to ensure that it is able to perform as expected when it is needed.

During equipment maintenance and upkeep, the cleanliness of the equipment should be maintained. Avoid leaving any debris or dirt on the equipment to prevent any impact on its normal operation. Secondly, pay attention to the temperature and pressure changes of the equipment. If abnormal temperature or pressure changes are found, maintenance should be immediately stopped and inspected.

After maintenance is completed, the equipment should be properly placed in a designated location or location. Ensure that the equipment is not corroded or damaged by natural factors such as wind and rain. At the same time, it is also necessary to ensure that the equipment does not affect the safety and normal activities of surrounding personnel. If there is any malfunction or damage to the equipment, professional personnel should be contacted immediately for repair or replacement. Do not attempt to repair or replace important components on your own to avoid greater losses or safety hazards.

7、Supplier

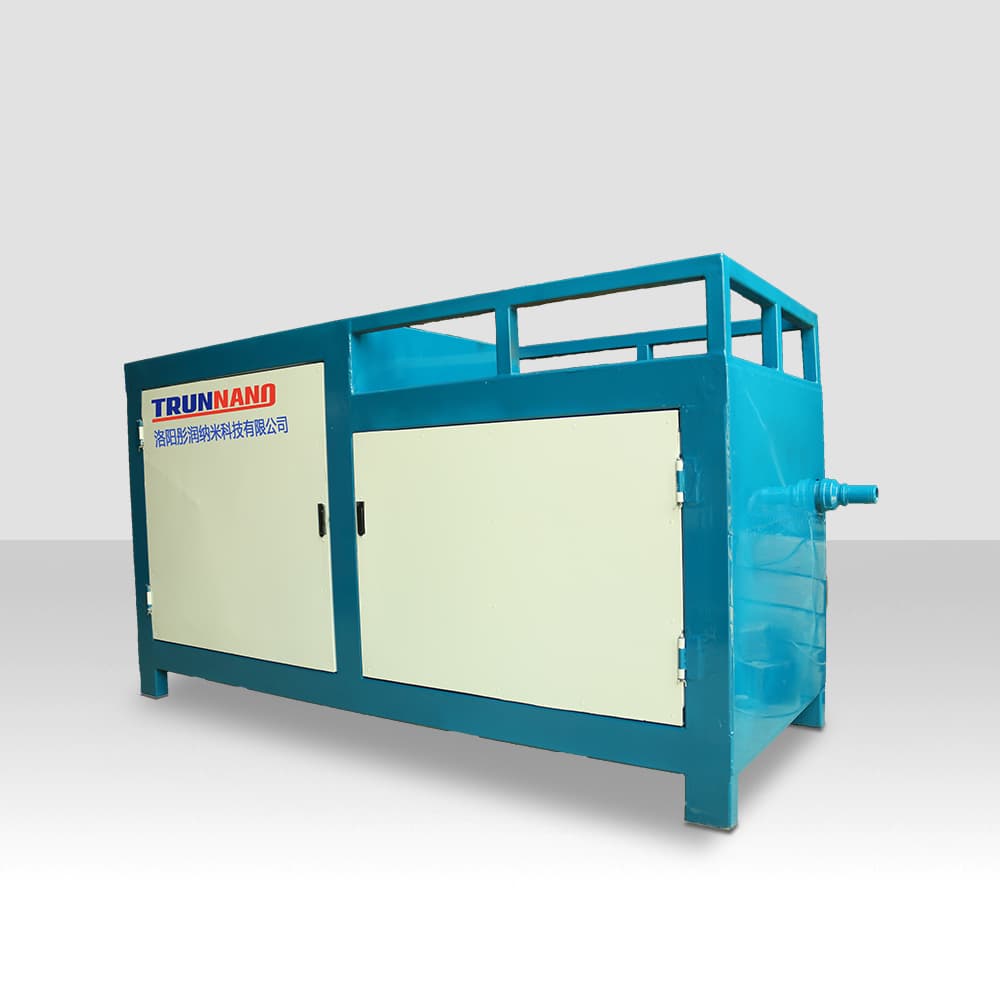

TRUNNANO is a supplier of foam agents with over 12 years experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. Trunnano will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for high-quality concrete additives, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com).

(What should be paid attention to in the safety production of foam generator?)