Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

Introduction: Polyvinyl alcohol fiber has high tensile strength and modulus due to its resistance to acid and alkali, aging, corrosion, and other properties.

Corrosion, UV resistance, and other properties, as well as no pollution or harm to the human body and the environment. It can effectively control the plastic shrinkage of concrete and

It can effectively control the generation and development of non-structural cracks, such as plastic shrinkage in concrete and mud mortar, effectively hinder the segregation of aggregates and the formation of settlement cracks, and improve the quality of concrete.

Cracks improve concrete’s seepage and impact resistance and increase its toughness and wear resistance, extending the building’s life.

The life span of the building can be extended.

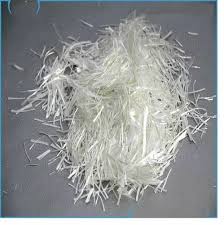

Technical principle: The product can be dispersed uniformly in concrete through special treatment and can continue to exert its effect for a long time.

The fibers are chemically grafted and physically modified, and their surface is rough and porous, which dramatically improves the bonding force between them and the cementitious material.

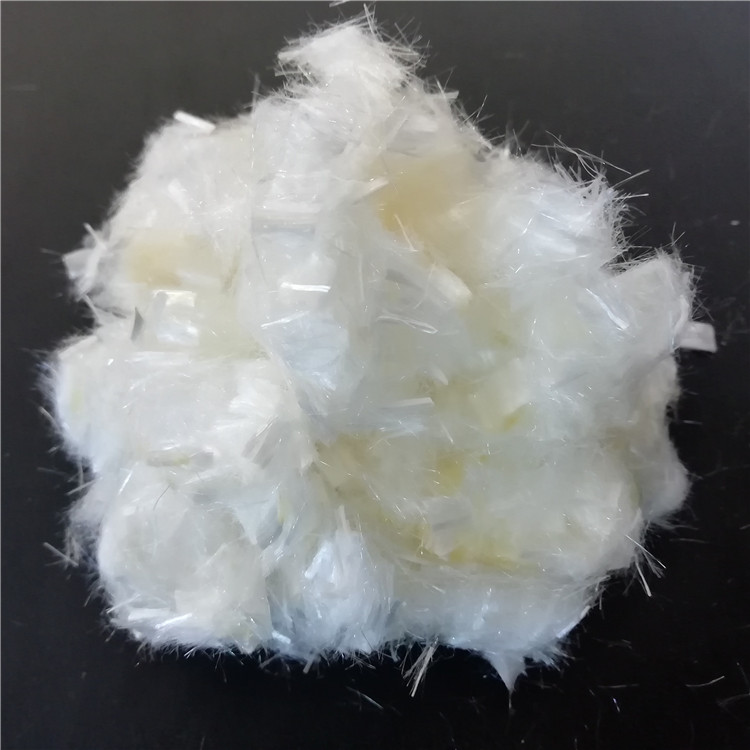

The fibers are chemically grafted and physically modified. High-strength and high-mode polyvinyl alcohol fiber can be added to the concrete base material and quickly and easily mixed with the mortar and concrete material.

The fibers can be quickly and easily mixed with the mortar and concrete materials. As the fibers are fine and have a large surface area, they can form a chaotic

support system inside the concrete, effectively controlling the generation and development of non-structural cracks such as plastic shrinkage of concrete and cement mortar.

Effectively hinder the segregation of aggregates, impede the formation of settlement cracks, and improve the concrete’s seepage and impact resistance.

Increase the toughness and abrasion resistance of concrete to prolong the life of the building and play the role of secondary reinforcement.

Manufacturing method: Polyvinyl alcohol high-strength high-modulus fiber (PVA) is the primary raw material of polyvinyl alcohol, which is dissolving, spinning, heat-setting, cutting, cutting, and cutting.

Silk, heat-setting, cutting, and packing are made of high-strength, high-modulus fiber. It is widely used and can be applied to various reinforcing materials.

It is widely used in building materials, safety nets, and industrial textiles.

Quality Indicators.

Product Performance

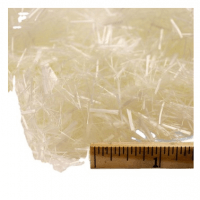

1、Appearance: slightly yellow

2、High strength and low elongation

3, Acid and alkali resistance: under high temperatures for a long time, the loss of strength is lower than in other fibers.

4, light resistance: When exposed to the sun for a long time, the fiber strength loss rate is much lower than that of other fibers.

5. Corrosion resistance: Fiber can be buried in the ground for a long time without mold, rot, or moth.

6, dispersion: the fiber is not sticky, has good dispersion in water, and has a good affinity with cement.

Main uses.

1、Cement reinforcing material. The fiber has high strength and good dispersing properties, is harmless and non-toxic, and has the characteristics of anti-corrosion, anti-insect moth, sunlight resistance, etc. It can be widely used in cement products and road construction, water conservancy projects, etc.

(1)Replacing asbestos to make high-strength cement products

(2)It can be used in road construction, especially in the construction of high-grade highways.

(3) Filament bundles can be used instead of steel bars as tension bands in the construction of water conservation projects.

(2) It can be made into high-strength ropes, safety nets, and high-strength industrial textiles.

3、It can be made into a tire cord, rubber reinforcing materials for conveyor belts, fire hoses, braided hoses, etc.

Fibre for textiles is not the same as that for concrete; if you ask for other uses, you can ask to give the technical parameters of use.

The way and so on.

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012’s.

We can supply polyethylene fibre (PVA fibre) all over the world. We have a professional technical department and quality supervision department, a well-equipped laboratory with advanced testing equipment and an after-sales customer service centre. Please send us an email or click on the required product to send an enquiry.

If you want to know more about Hydroxyethyl Cellulose HEC, please feel free and contact us: sales1@cabr-concrete.com

Payment

T/T, Western Union, Paypal, Credit Card etc.

Shipment

By air, by sea, by express, as customers request.