Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

Concrete is the most widely used building material globally and the foundation of modern infrastructure. The performance and durability of concrete are crucial for ensuring the lifespan and safety of buildings and structures. Among various admixtures used to improve the performance of concrete, accelerators play a crucial role by accelerating setting time and promoting early strength development.

Accelerator is a chemical admixture that can accelerate the hydration process of cement-based materials, thereby shortening the initial setting time and improving early strength gain. The main mechanism involves accelerating the rate at which cement particles react with water to form hydration products, such as calcium silicate hydrate (C-S-H) gel, calcium hydroxide (CH) and ettringite.

Calcium chloride (CaCl ₂) has become one of the most commonly used accelerators due to its effectiveness in cold weather concrete pouring. Its working principle is to lower the freezing point of water in the mixture, allowing the hydration reaction to continue even at sub-zero temperatures. However, CaCl ₂ has drawbacks, particularly its corrosiveness to steel reinforcement, which may lead to structural degradation over time.

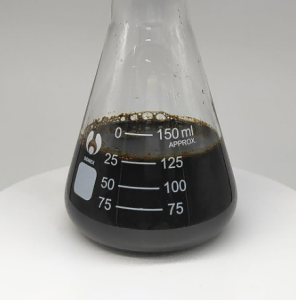

Calcium chloride is used for pouring concrete

Nonchloride accelerators have become safer alternatives, providing similar acceleration effects without corrosion risks. Common nonchloride accelerators include:

Calcium nitrite (Ca (NO ₂) ₂): It can be used as both a promoter and a corrosion inhibitor, making it suitable for reinforced concrete.

Sodium thiocyanate (NaSCN) promotes rapid hydration but must be used with caution to avoid adverse effects on long-term durability.Triethanolamine (TEA) enhances early strength development without affecting long-term performance.

Accelerators have been widely used in various building scenarios, where rapid solidification and early strength enhancement are crucial. For example:

Concrete pouring in cold weather: During the initial curing stage, accelerators can prevent freeze-thaw damage, thereby achieving year-round construction. They can undergo hydration reactions even at low temperatures, ensuring appropriate strength development.

Fast construction progress: Time-sensitive projects benefit from the shortened setup time provided by the accelerator. Early removal of templates has accelerated the traffic opening of roads and bridges, significantly improving project efficiency.

Improving workability and workability: Accelerators can enhance the workability of concrete by promoting faster hardening of the mixture, making pouring and finishing operations easier.

Enhanced durability: Nonchloride accelerators such as calcium nitrite can not only accelerate the improvement of early strength but also provide anti-corrosion protection, which contributes to the long-term durability of reinforced concrete structures.

Accelerators used in concrete represent a complex class of chemical admixtures that have significant advantages in early strength development, workability, and project efficiency. Although challenges related to long-term durability, compatibility, and environmental impact still exist, ongoing research and innovation are paving the way for more environmentally friendly and effective solutions. With the continuous development of the construction industry, the strategic use of accelerators remains crucial for building resilient and sustainable infrastructure that meets the needs of modern society. Through collaboration between scientists, engineers, manufacturers, and policymakers, we can unleash the full potential of accelerators and ensure that they make a positive contribution to the advancement of building technology.

Supplier

Cabr-Concrete is a supplier under TRUNNANO of Concrete Admixture with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for accelerator, please feel free to contact us and send an inquiry.sales@cabr-concrete.com