Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

In the constantly evolving field of construction, selecting appropriate additives can significantly affect the performance and sustainability of concrete structures. Fly ash (Class F and C), silica fume (micro silica), and ground granulated blast furnace slag (GGBS or GGBFS) are three prominent mineral admixtures that provide significant advantages for various types of concrete pouring applications.

Fly ash: Diversity of reactivity of volcanic ash

Fly ash has two primary grades – F grade and C grade – and has become the main component of modern concrete admixtures. F-grade fly ash is volcanic ash that reacts with calcium hydroxide to form additional calcium silicate hydrate (C-S-H), improving strength and durability. On the other hand, C-grade fly ash has volcanic ash and bonding properties, making it particularly effective in improving early strength development. This multifunctional additive reduces permeability, improves processability, and reduces hydration heat, which is crucial for large-scale infrastructure projects.

Fly ash

Silicon powder: ultra-precision

Silicon powder, also known as micro silica powder, stands out due to its ultrafine particles, which significantly reduce concrete’s permeability. By forming additional C-S-H, silicon powder can improve early and ultimate strength, making it an ideal choice for high-performance concrete applications. Its enhanced ability to resist chemical erosion and wear is unparalleled, ensuring long-term durability in harsh environments. This mineral admixture is particularly beneficial for key structures such as bridge decks and tunnel linings, where excellent performance is non-negotiable.

Silicon powder

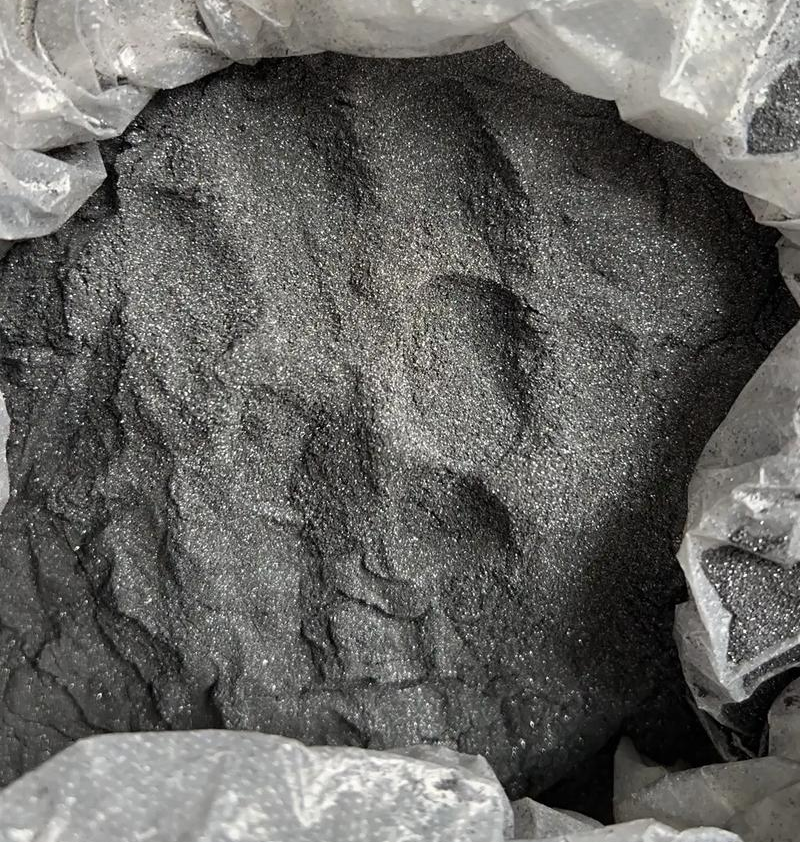

Ground ground blast furnace slag (GGBS): sustainable strength

GGBS originates from iron production and provides a sustainable solution for improving concrete performance. When ground into fine powder, GGBS acts as an auxiliary cementitious material (SCM), reducing hydration heat while improving long-term strength. It performs well in improving sulfate resistance and overall durability, making it an excellent choice for projects in marine or industrial environments. The use of GGBS also promotes environmental sustainability by utilizing waste from the steel industry.

The selection of suitable mineral admixtures depends on the specific requirements of each project, including environmental conditions, required performance characteristics, and the type of concrete pouring application. Fly ash provides multifunctionality and cost-effectiveness, silica fume offers precision and high performance, and GGBS ensures sustainable strength and durability. Each type of concrete admixture brings unique benefits, enabling construction professionals to optimize concrete mix proportions and improve efficiency and lifespan.

In summary, the continuous advancement of mineral admixtures continues to expand the possibilities for creating more durable, sustainable, and high-performance concrete structures. Whether through the volcanic ash reactivity of fly ash, the ultrafine precision of silica powder, or the sustainable strength of GGBS, these additives drive innovation in the construction industry.

Supplier

Cabr-Concrete is a supplier under TRUNNANO of Concrete Admixture with over 12 years of experience in nano-building energy conservation and nanotechnology development. It accepts payment via Credit Card, T/T, West Union and Paypal. TRUNNANO will ship the goods to customers overseas through FedEx, DHL, by air, or by sea. If you are looking for XXX, please feel free to contact us and send an inquiry. (sales@cabr-concrete.com)

Tags: Admixtures, types of concreting, concrete admixtures