Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

PRODUCT PARAMETERS

Description

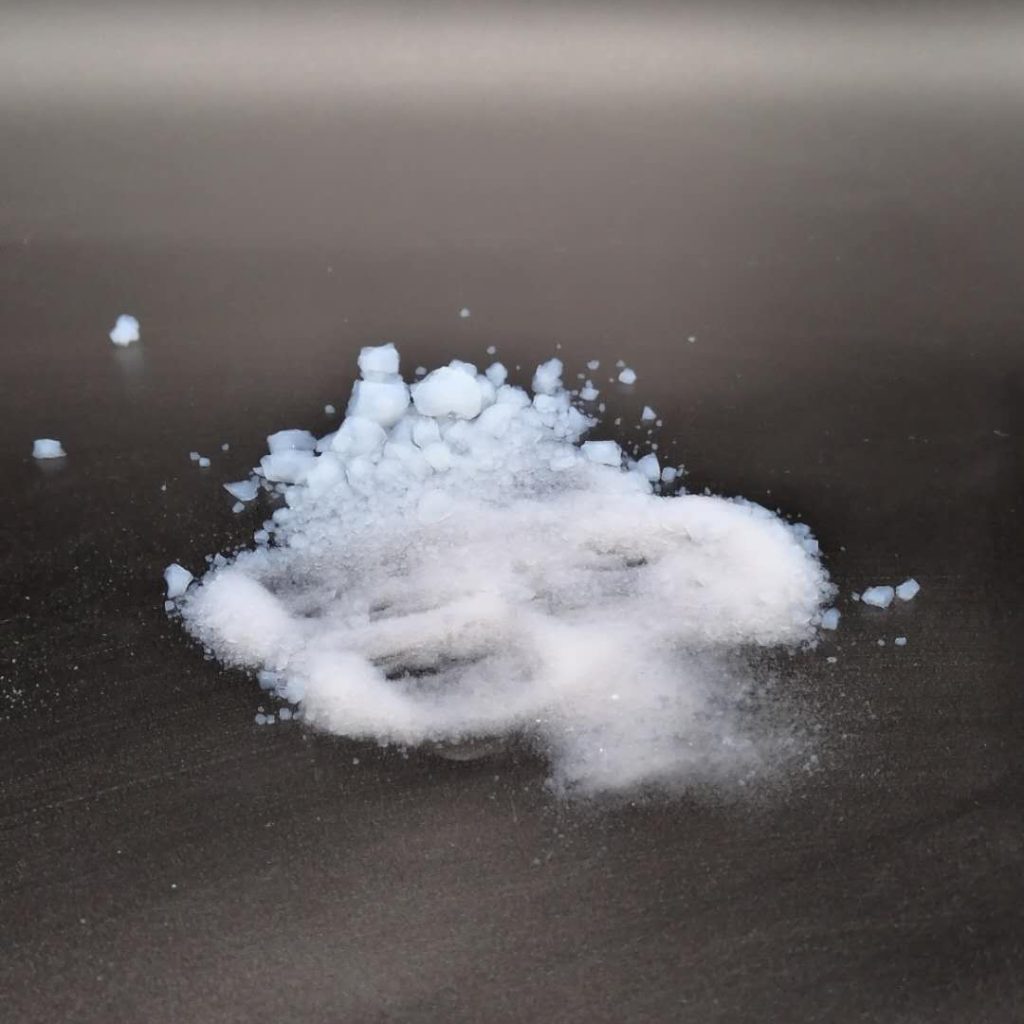

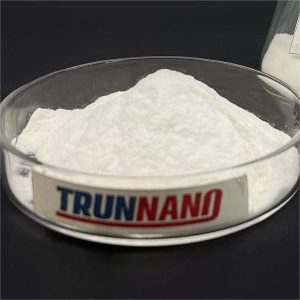

Overview of Aerogel Particles/Powder

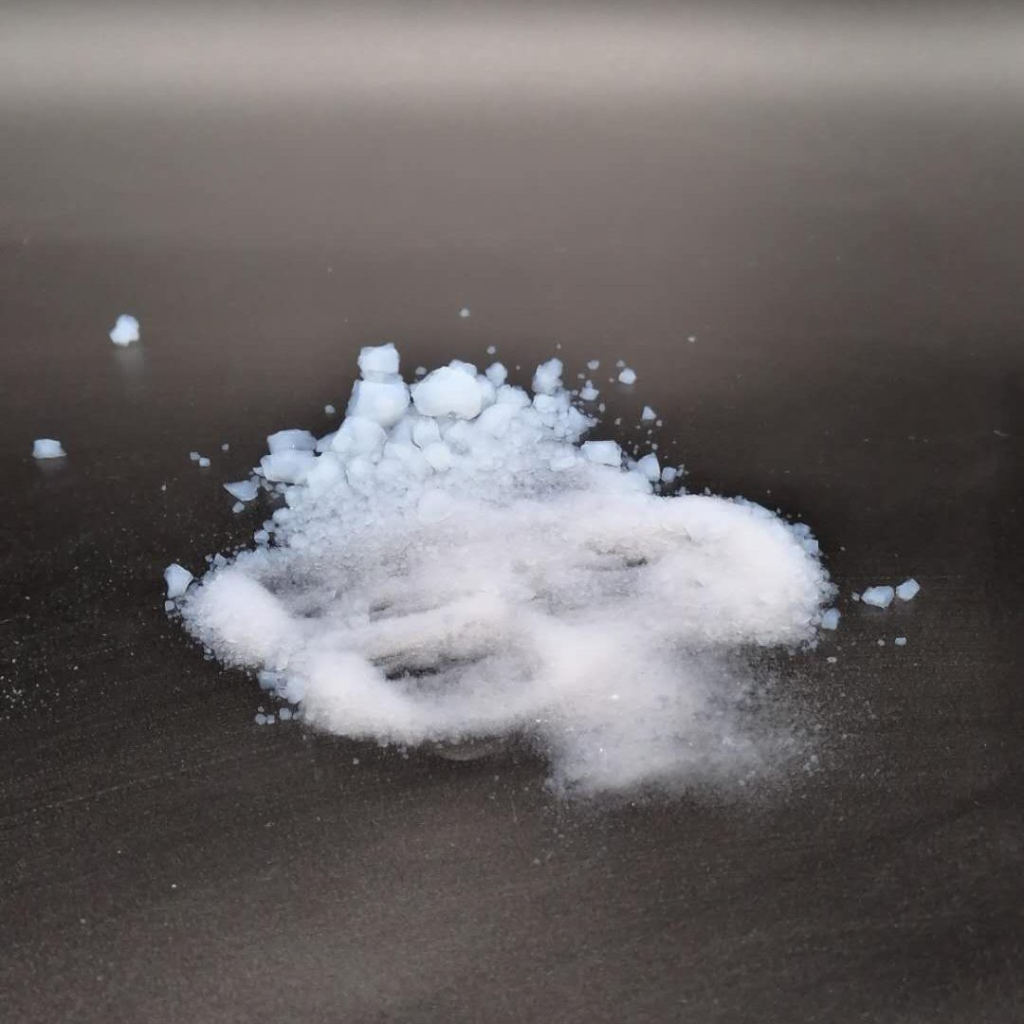

Aerogel powder is a porous solid material whose dispersion medium is gas.

The porosity rate is as high as 80-99.8%, the typical size of the pores is 1-100 nm, the specific surface area is 200-1000 m2/g, and the density of aerogel materials can be as low as 3 kg/m3.

Excellent thermal insulation performance: Aerogel is currently known as the solid material with the lowest thermal conductivity

Low thermal conductivity

Hydrophobicity> 99%

Class A flame retardant

Long service life

Very low density

Advantages of Aerogel Particles/Powder

- Thermal insulation, room temperature thermal conductivity is 0.018W/(m·K), and thermal insulation performance is 3~5 times that of traditional thermal insulation materials.

- Fireproof and hydrophobic, it can reach the national A-level non-combustible standard for building materials, and the hydrophobicity rate is ≥99%.

- Light weight and high strength, the product density is about 200kg/m3, with good flexibility and tensile strength.

- Long-lasting weather resistance, the aerogel insulation material is hydrophobic, not easily disintegrating and settling, and the service life can reach more than ten years.

- The service life of system insulation materials is increased by 3~5 times.

- Convenient construction can be processed into the required shape suitable for complex parts using ordinary cutting tools.

- Safe anti-corrosion aerogel can effectively prevent liquid water penetration and corrosion under the insulation layer.

- Healthy and environmentally friendly, the product has passed RoHS testing and does not contain substances harmful to the human body.

Data of Aerogel Particles/Powder

| Product Performance | |

| Performance | Hydrophobic |

| Main components | SiO2 |

| Micro particle size | <20 nm |

| Macro particle size | <20 um |

| Surface chemistry | Super-hydrophobic |

| Thermal conductivity | 0.017~0.022W/m.k |

| Density | <0.1g/cm3 |

| Specific surface area | 600-800m2/g |

| Porosity | >90% |

| Temperature | -200~1600 |

| Application | Thermal insulation, air purification, water treatment, catalyst carrier, etc. |

Application of Aerogel Particles/Powder

1. Aerospace thermal protection

2. New energy vehicle/battery field application

3. Oil pipeline field application

4. Ship/high-speed rail field, cold chain logistics field application

5. Construction field, defense field

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012’s.

We can supply high-quality concrete additives such as Potassium Silicate, Gypsum retarder and enhancer, Polyvinyl Alcohol Fiber, Concrete Crack Reducing Admixture, Hollow Glass Microspheres, Concrete strength and shrinkage reducer, Waterproof agent, Redispersible Polymer Powder (RDP) all over the world.

The company has a professional technical department and quality supervision department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.Send us an email or click on the needed products to send an inquiry: sales@cabr-concrete.com

Package of Aerogel Particles/Powder

25kg/200kg

If you want to know more about the concrete accelerator, please contact us at sales@cabr-concrete.com.

Payment

T/T, Western Union, Paypal, Credit Card etc.

Shipment

By air, by sea, by express, as customers request.

FAQs

Q1

What should you pay attention to when using concrete airgel powder particles?

Answer:

When using concrete airgel powder particles, you should fully understand their performance characteristics and usage requirements, and follow relevant construction specifications and operating procedures. At the same time, attention should be paid to safety measures at the construction site to avoid accidents due to improper operation or inadequate safety measures.

Q2

What are the advantages of concrete airgel powder particles compared to traditional concrete?

Answer:

Compared with traditional concrete, concrete airgel powder particles have the advantages of light weight, high strength, thermal insulation, and environmental protection. It can effectively reduce the weight of the building structure, improve the strength and stability of the structure, and at the same time provide good thermal insulation effects, reduce the energy consumption of the building, and does not produce harmful substances during the production process, making it environmentally friendly.

Q3

How durable are concrete airgel powder particles?

Answer:

The durability of concrete airgel powder particles mainly depends on the quality of its raw materials and preparation process. Under normal circumstances, the service life of concrete airgel powder particles can reach decades or even hundreds of years, with good durability. At the same time, special treatment measures can be taken on its surface to improve its durability and anti-aging properties.

Q4

How are concrete airgel powder particles prepared?

Answer:

The preparation of concrete airgel powder particles mainly includes the following steps: first crush the concrete material into powder, then add the airgel material for mixing, then remove the moisture and organic solvents through high temperature treatment, and finally dry and screen to obtain the final product. product.

Q5

What are the applications of concrete airgel powder particles in the construction field?

Answer:

The applications of concrete airgel powder particles in the construction field mainly include: thermal insulation, sound insulation, fire protection, etc. It can be used as a thermal insulation material for wall admixtures, floor cushions, basements, etc. It can also be used to enhance the compressive and tensile strength of concrete.