Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

PRODUCT PARAMETERS

Description

Overview of HPMC Hydroxypropyl Methylcellulose

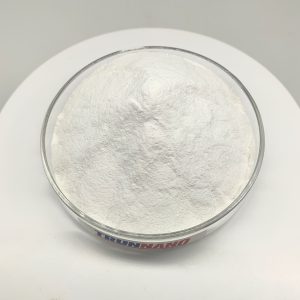

Hydroxypropyl methylcellulose HPMC is a Non-ionic cellulose ether made from natural polymer cellulose through chemical processing.

Through the recombination of HPMC and nano-materials, nanocomposite Hydroxypropyl methylcellulose reduces its

hydrophilicity and improves the membrane permeability of HPMC. At the same time, it can also ensure that it has good

mechanical properties and can be widely used in many fields.

HPMC powder

Water Solubility and Thickening Ability

Hydroxypropyl methylcellulose can be dissolved in cold water to form a transparent viscous solution.

Dissolution in organic solvents: Because hydroxypropyl methylcellulose contains a certain amount of hydrophobic methoxy groups, this product can be dissolved in some organic solvents, and it can also be dissolved in water and organic solvents.

Characteristics of HPMC Hydroxypropyl Methylcellulose

Salt resistance

HPMC Powder is a non-ionic polymer; it is relatively stable in the aqueous solution of metal salt or organic electrolyte. Surface activity: The aqueous solution of this product has surface activity, emulsification, protective colloid, and relatively stable functions and properties.

Thermal gelation

The aqueous hydroxypropyl methylcellulose solution becomes impermeable when heated to a certain temperature until a (poly) flocculation state is formed, making the solution lose its viscosity. But after cooling, it will be transformed into the original solution state. The gel phenomenon’s temperature depends on the type of product, the concentration of the solution, and the heating rate.

Low ash content

Because hydroxypropyl methylcellulose has thermal gelling properties, HPMC can be effectively refined by washing with hot water during preparation, so its ash content is very low.

PH stability: The viscosity of the aqueous solution of hydroxypropyl methylcellulose is stable within the range of PH3.0-11.0.

Water retention

HPMC is hydrophilic; it can be added to mortar, gypsum, paint, etc., to maintain high water retention in the product.

Shape retention

Compared with other water-soluble polymers, the deep liquid of hydroxypropyl methylcellulose has special viscoelastic properties. Its addition can keep the shape of extruded ceramic products unchanged, etc.

Lubricity

Adding HPMC can reduce the coefficient of friction and improve the lubricity of extruded ceramic and cement products.

Film formation

Hydroxypropyl methylcellulose can produce flexible, transparent, and excellent mechanical properties and has good oil and grease resistance.

Physical and Chemical Properties of Hydroxypropyl Methylcellulose

| Property | Description |

|---|---|

| Chemical Formula | No simple formula; it is a polymer with varying degrees of substitution. |

| Molecular Weight | Varies depending on the degree of polymerization; typically ranges from 8,000 to 125,000 Da. |

| Appearance | White to off-white, odorless, tasteless powder. |

| Solubility | Soluble in cold water but insoluble in hot water (>60°C). Forms viscous solutions. |

| Viscosity | Depends on concentration and molecular weight; typically measured in centipoise (cP) at 2% w/v solution. |

| pH Range for Stability | Stable over a wide pH range (3-11); most stable between pH 4-8. |

| Thermal Stability | Decomposes above 200°C; onset of thermal degradation around 180°C. |

| Glass Transition Temperature (Tg) | Approximately 160-190°C, depending on moisture content and degree of substitution. |

| Melting Point | Does not have a defined melting point due to its polymeric nature; decomposes before melting. |

| Water Retention | High water retention capacity, important for applications like mortar and plaster. |

| Surface Tension | Reduces surface tension of aqueous solutions, aiding in film formation. |

| Film Formation | Forms flexible, transparent films that are resistant to oils and greases. |

| Swelling Capacity | Swells significantly in water, contributing to thickening and gelling properties. |

| Degree of Substitution | Methoxyl (–OCH₃) groups: 19-30%; Hydroxypropyl (–OCH₂CH(OH)CH₃) groups: 4-12%. |

| Bulk Density | Typically ranges from 0.4 to 0.6 g/cm³. |

| Moisture Content | Usually less than 12% by weight. |

| Particle Size | Fine to medium-sized particles, with particle size distribution affecting solubility and dissolution rate. |

| Hygroscopicity | Slightly hygroscopic; absorbs moisture from the air, which can affect storage stability. |

| Biodegradability | Biodegradable under certain conditions; however, degradation rate is slow. |

| Toxicity | Generally recognized as safe (GRAS) by the FDA for use in food and pharmaceutical products. |

| Compatibility | Compatible with many organic and inorganic compounds but may interact with strong acids or bases. |

| Freezing Point Depression | Capable of lowering the freezing point of water-based solutions. |

| Boiling Point Elevation | Can increase the boiling point of water-based solutions. |

HPMC Hydroxypropyl Methylcellulose Applications

HPMC Hydroxypropyl Methylcellulose Applications

1. Cement mortar: Hydroxypropylmethylcellulose increases its dispersibility in cement sand. It significantly improves the flexibility and the retention of water in mortar. It can help prevent cracks and also increase the toughness of cement.

2. Tile cement improves the flexibility and water retention of the tile mortar that has been pressed, increases the adhesive force of the tile, and stops chalking.

3. Coating of refractory materials, such as asbestos, is an agent for suspension and a fluidity enhancer; it also increases the adhesion of the substrate.

4. Gypsum coagulation Slurry: Improves the processability and retention of water, as well as enhances adhesion to the substrate.

5. Joint cement is used in conjunction with joint cement Gypsum board to increase its fluidity and retention of water.

6. Latex putty: increase the water retention and fluidity of resin-based putty latex.

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012’s.

We can supply high-quality concrete additives such as Potassium Silicate, Gypsum retarder and enhancer, Polyvinyl Alcohol Fiber, Concrete Crack Reducing Admixture, Hollow Glass Microspheres, Concrete strength and shrinkage reducer, Waterproof agent, Redispersible Polymer Powder (RDP) all over the world.

The company has a professional technical department and quality supervision department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center. If you are looking for high-quality hydroxypropyl methylcellulose, please feel free to contact us and send an inquiry: sales@cabr-concrete.com

Payment Method

We accept payment via Credit Card, T/T, West Union, and Paypal.

Shipment

FedEx, DHL, by air, or by sea

FAQs

Q1

How many types of HPMC are there?

Answer:

HPMC can be divided into construction grade, food grade and pharmaceutical grade according to its use.

Q2

What is the gel temperature of HPMC related to?

Answer:

The gel temperature of HPMC is related to its methoxy group content. The lower the methoxy group content, the higher the gel temperature.

Q3

Is the powder loss of putty related to HPMC?

Answer:

The loss of putty powder is mainly related to the quality of gray calcium and has little to do with HPMC. The low calcium content of gray calcium and the inappropriate ratio of CaO and Ca(OH)2 in gray calcium will cause powder loss.

Q4

What is the water retention of HPMC?

Answer:

HPMC has good water retention, but poor water retention may cause the putty powder to fall off.

Q5

What is the thickening principle of HPMC?

Answer:

HPMC is a high molecular polymer. Its thickening principle is to form a viscous colloidal solution at a lower concentration through the stretching and adsorption of its molecular chain.

Q6

What are the advantages of HPMC?

Answer:

HPMC has the advantages of good stability, dispersion, film-forming properties and enzyme resistance, and can be widely used in various fields.

Q7

What is the production process of HPMC?

Answer:

The production process of HPMC mainly includes cellulose etherification reaction and post-treatment process. The etherification reaction is a key step in the production of HPMC. It is necessary to control the reaction conditions such as temperature, pressure, material ratio, etc.

Q8

How to store and transport HPMC?

Answer:

When storing and transporting HPMC, attention should be paid to moisture-proof, sun-proof, dust-proof and anti-pollution measures. It should be stored in a dry, cool and well-ventilated place, away from direct sunlight and high temperature. Collision and extrusion should be avoided during transportation to prevent packaging damage and product deterioration.