Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

Concrete Fiber

Copper-plated steel fibres

Innovative high-performance polypropylene fibres (PP fibres) for concrete and mortars

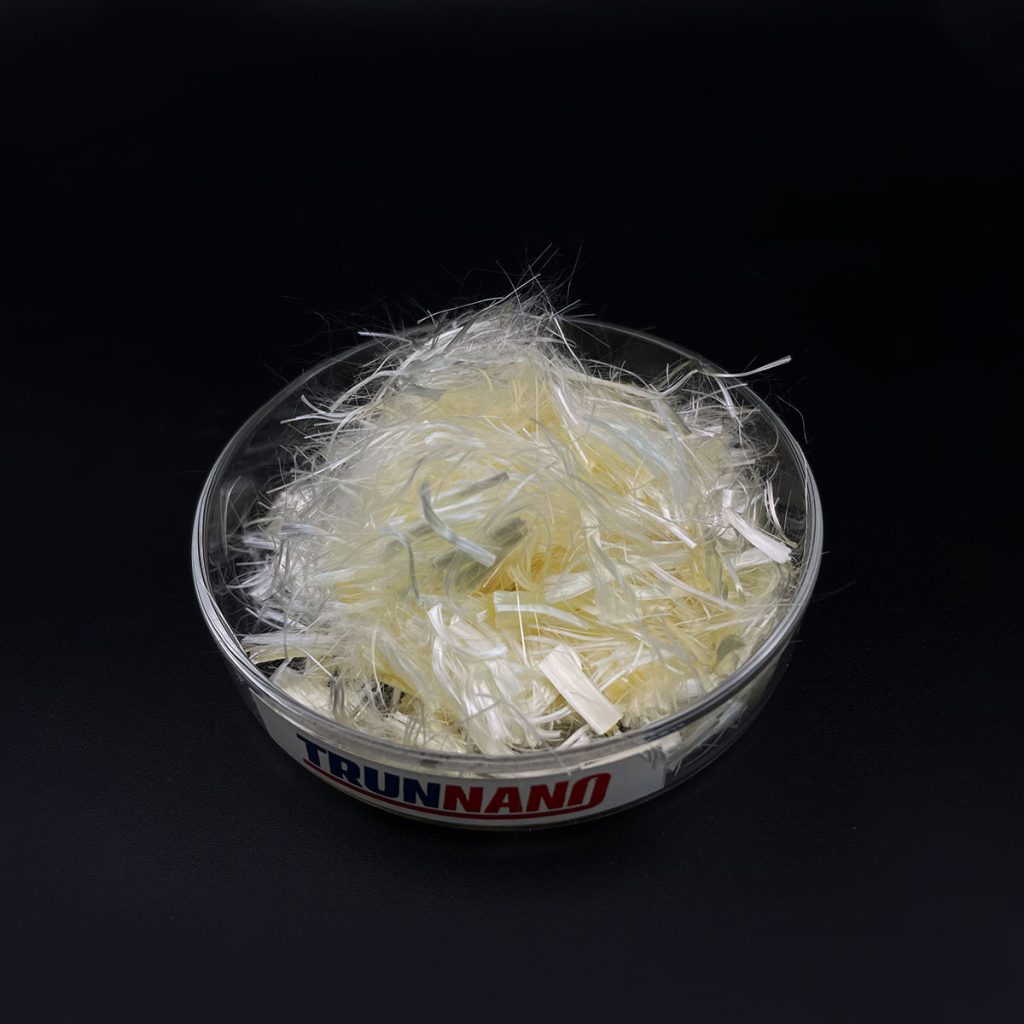

Polyvinyl alcohol (PVA) fibres

Copper-Coated Microfilament Steel Fiber Fibre for Concrete Use

Shearing Steel Fiber Construction Steel Shearing Type Wave Steel Fiber for Concrete Use

Milling Steel Fiber Mill-Cut Hooked Concrete Steel Fiber Concrete Binder Architecturally Acicular Steel Fiber

End Hook Steel Fiber for Concrete Reinforcement Steel Fiber

Factory Row Steel Fiber Price for Row Steel Fiber Concrete Hot Sale

UHMWPE Fiber Ultra High Molecular Weight Polyethylene Fiber For Concrete Use

Aramid Fiber Aromatic Nylon For Concrete Use

Chopped Carbon Fiber Products for Concrete Use

Wholesale Price Basalt Fiber High Strength Basalt Fiber Rebar Basalt Fiber Reinforced Composite Rebar For Concrete

Overview of concrete fiber

Fiber used in construction projects is a thin and long material with an aspect ratio of generally more than 100, and has a certain tensile strength (also called breaking strength), elastic modulus (also called initial modulus) and ultimate elongation (also called breaking elongation). The fibers used in construction projects mainly refer to short-segment discontinuous fiber materials that can be evenly distributed in concrete and can strengthen the concrete structure.

According to the different fiber materials used, they can be divided into: natural fibers or artificial fibers; organic fibers or inorganic fibers, etc. Specifically, they can be divided into natural organic fibers (various hemp fibers, wood pulp fibers, coconut shell fibers (collectively referred to as cellulose fibers) and animal bristles, etc.); natural inorganic fibers (asbestos fibers, needle-shaped wollastonite, etc.), artificial organic fibers (also called synthetic fibers: polypropylene fibers, polyacrylonitrile fibers, polyvinyl alcohol fibers, polyester fibers, polyamide fibers, ultra-high molecular weight polyethylene fibers, etc.), and artificial inorganic fibers (metal fibers, glass fibers, basalt fibers, mineral wool fibers, and carbon fibers, etc.). According to the different elastic modulus of the fiber used, that is, whether the elastic modulus of the fiber is higher or lower than the elastic modulus of the matrix it is mixed with, it can be divided into high elastic modulus fiber and low elastic modulus fiber; according to the different matrix materials it is mixed with, it can be divided into: fiber for cement concrete, fiber for mortar (cement paste), fiber for asphalt concrete, etc.

Fiber concrete can be regarded as a concrete compounded with a certain amount of short, uniformly dispersed, and discontinuous fibers added to ordinary concrete. The combination of fiber and concrete matrix improves the inherent weaknesses of concrete and has a multi-faceted impact on the performance of concrete. The improvement of the crack resistance and durability of fiber concrete is of great significance to the construction of high-quality, beautiful and durable projects.

The role of fiber in concrete

Including fiber to concrete can increase the strength and split resistance of the material, and at the same time has a specific impact on the strength and rigidity of concrete

Boost the tensile toughness of concrete

The stamina of concrete generally comes from the cement and accumulation in the mixture. The tensile strength of concrete is extremely reduced. Adding a proper amount of fiber can make concrete have better tensile toughness, thus boosting the total strength of the concrete structure.

Enhance the sturdiness of concrete

The fiber in concrete can enhance the residential or commercial properties of microcracks in concrete, minimize the water leaks in the structure and air permeability in concrete, boost the frost resistance and sturdiness of concrete, and thus extend the service life of concrete.

Boost the influence performance of concrete.

After adding fiber, the energy absorption capability of concrete can be enhanced, therefore improving the influence performance of concrete and minimizing the degree of stamina reduction.

Types of fibers

Steel fiber

Metal fiber is a standard fiber contributed to concrete, such as steel fiber, aluminum alloy fiber, and so on. They have high toughness and large ductility. After adding them to concrete, they can enhance the seismic resistance and crack resistance of concrete, yet steel fiber is prone to rust.

Synthetic fiber

Artificial fiber products have good deterioration resistance and alkali resistance, mainly polypropylene fiber and nylon fiber, and so on. The addition of these fibers can efficiently enhance the fracture resistance and bending and tensile resistance of concrete, thus improving the overall performance of concrete.

Glass fiber

Glass fiber is cheap and is included big amounts. It is made use of greater than iron cable. It can boost the fracture resistance and impermeability of concrete and is challenging to corrosion.

The result of fiber on concrete toughness

The impact of fiber on concrete stamina generally consists of the following aspects:

Fiber type and size

Fibers of different types and sizes have various impacts on the stamina of concrete. Generally speaking, the longer the fiber length, the greater the result on the stamina of concrete.

Fiber enhancement

The quantity of fiber included likewise has a wonderful impact on the strength of concrete. Inadequate will certainly have virtually no result, while too much might cause the strength of concrete to lower.

Fiber circulation

Irregular circulation of fibers might trigger the strength of concrete to reduce, so when adding fibers, it is needed to pay attention to the full mixing of concrete and fibers.

Applications of Concrete Fiber

Building and construction: Used in slabs, pavements, bridge decks, and precast elements to raise durability and decrease upkeep.

Roadways and Freeways: Improves toughness and decreases the threat of fractures and rutting.

Industrial Floors: Gives resistance to heavy tons and influence in storehouses and manufacturing facilities.

Repair: Ideal for overlays and repair services where rapid stamina gain and very little downtime are needed.

Residential Projects: Made use of driveways, patio areas, and walkways to stop fracturing and improve visual appeals.

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012's.

We can supply high-quality Concrete Fiber. The company has a professional technical department and quality supervision department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.Send us an email or click on the needed products to send an inquiry.

If you want to know more about Concrete Fiber, please feel free and contact us: sales@cabr-concrete.com

Package of Concrete Fiber

25Kg woven outer bag lined with plastic bag, stored at room temperature away from light, moisture and rain.

Storage of Concrete Fiber

Paper plastic composite packaging lined with plastic bags.

FAQs of Concrete Fiber

Q: How do fibers improve concrete?

A: Fibers act as internal reinforcement, bridging micro-cracks and improving the overall mechanical properties of the concrete.

Q: Are concrete fibers costly?

A: The cost differs depending upon the sort of fiber and quantity required. Typically, while fibers might contribute to initial prices, they can decrease long-term expenditures via enhanced toughness and fewer repair work.

Q: Can concrete fibers change rebar?

A: While fibers boost several aspects of concrete performance, they typically do not completely change traditional rebar in important load-bearing frameworks. Nevertheless, they can often decrease the amount of rebar needed.

Q: Exist any kind of environmental interest in using concrete fibers?

A: The ecological impact depends on the type of fiber made use of. Synthetic fibers are stemmed from petrochemicals, whereas all-natural fibers are biodegradable but may have restricted performance. Sustainability factors to consider ought to direct the selection of fiber type.

Q: Just how do I mix concrete fibers?

A: Fibers are normally added directly to the concrete mixer at the specified dose rate. Proper mixing guarantees uniform distribution throughout the concrete. Maker guidelines should constantly be followed.