Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

PRODUCT PARAMETERS

Description

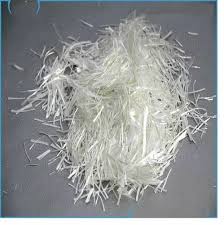

Introduction of Alkali-resistant Glass Fiber

Alkali-resistant glass fiber is the rib material of glass fiber reinforced concrete (GRC for short). It is 100% inorganic fiber and is an ideal substitute for steel and asbestos in non-load-bearing cement components. Alkali-resistant glass fiber is characterized by good alkali resistance, can effectively resist the erosion of high-alkali substances in cement, strong bond strength, extremely high elastic modulus, impact resistance, tensile strength, and flexural strength, non-flammability, frost resistance, temperature and humidity change resistance, excellent crack resistance and impermeability, strong designability and easy molding. Alkali-resistant glass fiber is a new type of green and environmentally friendly reinforcement material widely used in high-performance reinforced concrete.

Function of Alkali-resistant Glass Fiber

1. Improve the flexural properties of hardened concrete.

2. Control and prevent cracking of fresh concrete, hardened concrete and mortar (plastic shrinkage cracking, shrinkage and thermal shrinkage cracking, and load cracking).

3. Evenly mixed and high efficiency. Not easy to corrode.

4. Good pumping performance. Low water consumption.

5. High doses do not affect process performance

Parameters of Alkali-resistant Glass Fiber

| Fiber length | 12mm 24mm 36mm | Material | Alkali-resistant glass |

| Loss on ignition % | 2.00±0.4 | Fiber diameter | 19um±20% |

| Moisture content % | ≤0.5 | Softening point | 098 |

| Elastic modulus | >72Gpa | Specific gravity | 2.68g/cm |

| Conductivity | Very low | Chemical resistance | Very high |

| Tensile strength | 1000-1700Mpa | Zirconium oxide content | 16.7% |

Usage of Alkali-resistant Glass Fiber

Recommended dosage: secondary reinforcement 1.5kg-5kg/m³, primary reinforcement, reinforced floor 5kg-15kg/m3

Mixing process: add aggregate → add fiber → add cement → add water → stir → add water to disperse all the fibers.

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012’s.

We can supply Concrete Fiber over the world. The company has a professional technical department and quality supervision department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.Send us an email or click on the needed products to send an inquiry.

If you want to know more about Alkali-resistant Glass Fiber, please feel free and contact us: sales@cabr-concrete.com

Packaging and Storage of Alkali-resistant Glass Fiber

Packaging: inner plastic bag 1kg-5kg per small bag, outer woven bag or carton 10kg-25kg per bag, 500kg per pallet, can also be produced and packaged according to user requirements.

Payment

T/T, Western Union, Paypal, Credit Card etc.

Shipment

By air, by sea, by express, as customers request.

FAQs of Alkali-resistant Glass Fiber

Q: Why is alkali-resistance important in glass fibers?

A: Alkali-resistance is crucial because standard glass fibers can degrade when exposed to the highly alkaline environment of concrete, leading to a loss of strength over time. AR glass fibers maintain their integrity and performance in such environments, ensuring long-term durability.

Q: What are the typical components of alkali-resistant glass fiber?

A: AR glass fibers are typically composed of a base glass formulation that includes additives such as zirconia (ZrO₂), alumina (Al₂O₃), or calcia (CaO) to improve resistance to alkali attack. The exact composition can vary depending on the manufacturer and specific application requirements.

Q: How is alkali-resistant glass fiber manufactured?

A: The manufacturing process involves melting a mixture of raw materials to form a glass, which is then cooled and drawn into fine fibers. The composition is specifically engineered to resist alkali attack. The fibers are often coated with a sizing that further improves compatibility with matrix materials and enhances handling.

Q: Can alkali-resistant glass fiber be recycled?

A: The recyclability of AR glass fiber depends on the specific composition and the condition of the fiber after use. While glass itself is theoretically recyclable, the presence of additives and coatings may complicate the recycling process. Specialized recycling processes may be necessary to reclaim the glass content.

REQUEST A QUOTE

RELATED PRODUCTS

PP Series Polypropylene Crude Synthetic Fiber

Shearing Steel Fiber Construction Steel Shearing Type Wave Steel Fiber for Concrete Use

High Quality Lignin Fiber Organic Fiber for Concrete Use

End Hook Steel Fiber for Concrete Reinforcement Steel Fiber

PVA Fibers for Concrete Reinforcement in a Variety of Concrete Mixes