Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

PRODUCT PARAMETERS

Description

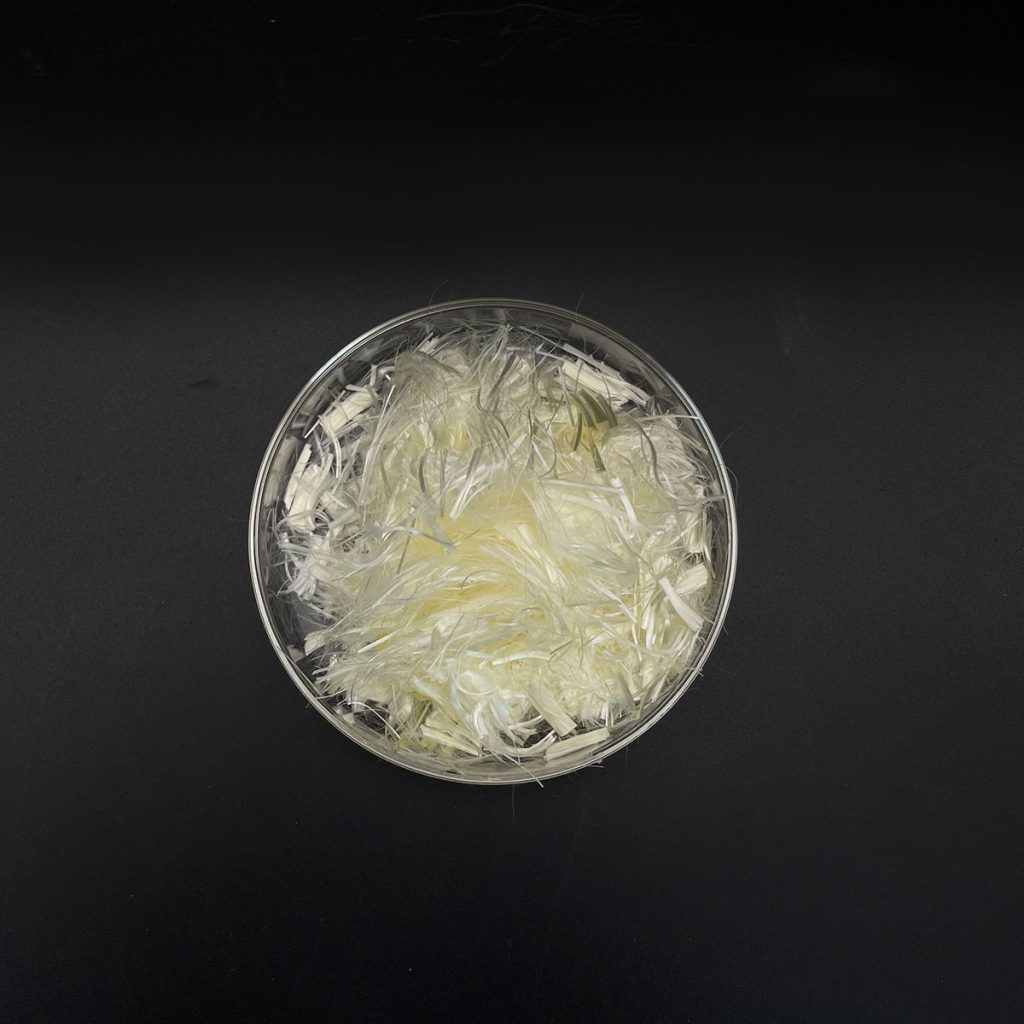

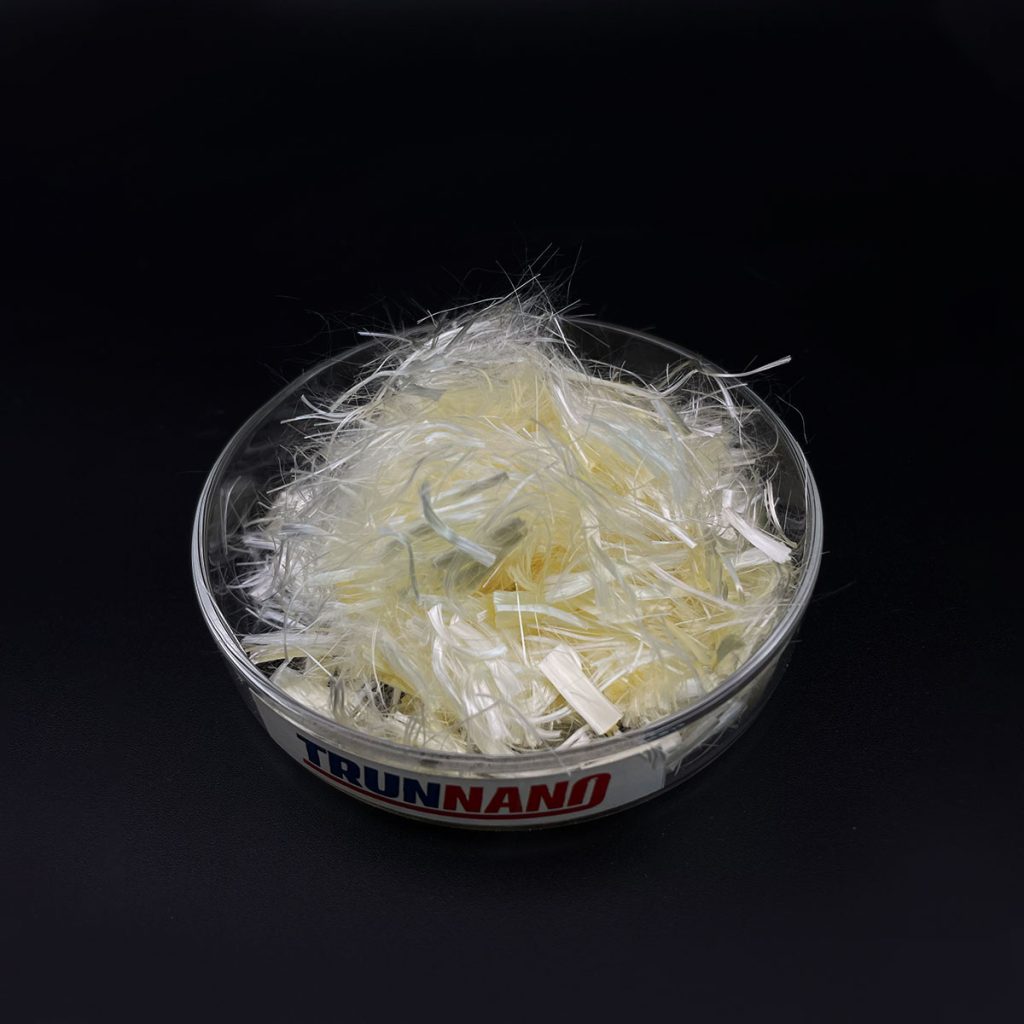

Introduction of Floor Special Polypropylene Synthetic Stranded High Strength Fiber

Basic raw material: polypropylene

Floor special polypropylene synthetic stranded high strength fibers are engineered additives designed to enhance the durability, crack resistance, and overall performance of concrete and mortar used in flooring applications. These fibers are typically manufactured from high-quality polypropylene and are engineered to be evenly distributed throughout the concrete mix. Their unique stranded design provides superior tensile strength and increases the concrete’s resistance to shrinkage cracks, thereby prolonging the lifespan of the floor.

Basic Characteristics of Floor Special Polypropylene Synthetic Stranded High Strength Fiber

1, its high strength stranded and other characteristics determine its excellent performance in concrete floor, more suitable for the application of floor. Its fatigue resistance, no memory, so that the floor outcrop phenomenon is less, more easy to take care of, reduce labor costs, greatly shorten the construction time.

2,the characteristics of polypropylene determine that it is more suitable for harsh environment, without worrying about corrosion.

3, its comprehensive characteristics are more suitable for pouring concrete,high strength, corrosion resistance, low cost, become a new type of material workers prefer to operate, a environmentally friendly product.

Parameters of Floor Special Polypropylene Synthetic Stranded High Strength Fiber

| Fiber category | Floor specific polypropylene Synthetic stranded – linked high – strength fiber |

| Tensile strength | ≥650MPa |

| Modulus of elasticity | 9GPa |

| Long degrees | 44mm |

| Equivalent diameter | 0.7~1mm |

| Base material | polypropylene |

| Surface treatment | Hank league form |

| Alkali resistance | Very good |

Typical Application Scope of Floor Special Polypropylene Synthetic Stranded High Strength Fiber

Industrial floor, concrete platform floor, pavement and pavement.

Recommended Dosage of Floor Special Polypropylene Synthetic Stranded High Strength Fiber

generally 3kg/m3~5kg/m3, the specific dosage depends on the actual application engineering.

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012’s.

We can supply Concrete Fiber over the world. The company has a professional technical department and quality supervision department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.Send us an email or click on the needed products to send an inquiry.

If you want to know more about Floor special polypropylene synthetic stranded high strength fiber, please feel free and contact us: sales@cabr-concrete.com

Packaging and Storage of Floor Special Polypropylene Synthetic Stranded High Strength Fiber

10kg/ bag, it can be customized according to customer requirements.

Payment

T/T, Western Union, Paypal, Credit Card etc.

Shipment

By air, by sea, by express, as customers request.

FAQs of Floor Special Polypropylene Synthetic Stranded High Strength Fiber

Q: Are there any environmental benefits to using these fibers?

A: Yes, polypropylene fibers can contribute to more sustainable construction practices by reducing the need for additional maintenance and repair, thus lowering the lifecycle cost and environmental impact of the flooring system.

Q: How do I store these fibers before use?

A: Store the fibers in a clean, dry area away from direct sunlight and moisture. Ensure the packaging is intact and undamaged until ready for use.

Q: Can these fibers be used in outdoor applications?

A: Yes, these fibers can be used in outdoor applications. They are resistant to UV light and environmental factors, making them suitable for exterior concrete flooring projects.

Q: What safety precautions should be taken when handling these fibers?

A: When handling the fibers, wear appropriate personal protective equipment (PPE) such as gloves and safety glasses to prevent inhalation and skin irritation. Ensure good ventilation during the mixing process.

Q: How do I dispose of unused fibers?

A: Dispose of unused fibers according to local waste management regulations. Do not dump them into the environment; instead, seek guidance from local authorities on how to dispose of construction materials responsibly.

REQUEST A QUOTE

RELATED PRODUCTS

Plastic Steel Fiber Polypropylene Crude Fiber Polypropylene Concrete Reinforcing Fibers Better Than Steel Fiber

Polypropylene Monofilament Fiber for Concrete

Polyvinyl alcohol (PVA) fibres

High Quality Lignin Fiber Organic Fiber for Concrete Use

PP Series Polypropylene Crude Synthetic Fiber