Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

PRODUCT PARAMETERS

Description

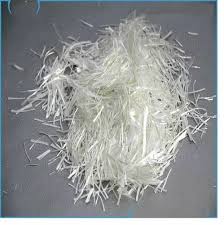

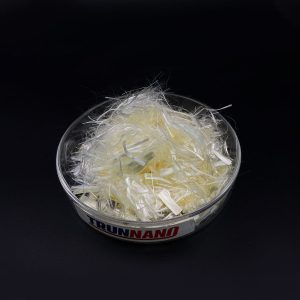

Introduction of Alkali Free Glass Fiber

Alkali-free glass fiber is an excellent inorganic fiber for enhancing the anti-seepage and anti-cracking of mortar concrete. It is also a highly competitive product for replacing polyester fiber, lignin fiber, etc. for enhancing mortar concrete. It can also improve the high temperature stability, low temperature crack resistance and fatigue resistance of asphalt concrete and extend the service life of road surface. Cement concrete/mortar anti-cracking and anti-seepage fiber, after being added to concrete, has good dispersibility, strong bond strength with cement concrete matrix, and has obvious advantages such as anti-cracking, enhanced anti-seepage, anti-freezing and impact resistance.

Function of Alkali Free Glass Fiber

1. Stable structure, improve the high temperature stability, low temperature crack resistance and extend the service life of road surface of asphalt concrete.

2. Good dispersibility, cement concrete/mortar anti-cracking and anti-seepage fiber. After the fiber is added to concrete, it has strong bond strength with cement concrete matrix.

3. Not easy to corrode, no matter under strong acid, strong alkali and other conditions, it will not be affected.

Parameters of Alkali Free Glass Fiber

| Material | Alkali-free glass fiber |

| Cut length | 80-1500 mesh powder |

| Tensile strength | Chopped: 3-100mm |

| Density | 600-1500mpa |

| Combustible content | 2.7g/cm3 |

| Moisture content | 1.75% |

Application of Alkali Free Glass Fiber

1. National defense engineering, etc.

2. Tunnel shotcrete, etc.

3. Bridge engineering, etc.

4. Subway engineering, etc.

5. Airport runway, etc.

6. Water conservancy projects, etc.

7. Top floors, internal and external walls, basements, etc. of buildings.

8. Paint, etc.

Usage of Alkali Free Glass Fiber

Recommended dosage: 2-6kg/m3.

Mixing process: Add aggregate → Add fiber → Add cement → Add water → Stir and add water to disperse all the fibers.

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012’s.

We can supply Concrete Fiber over the world. The company has a professional technical department and quality supervision department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.Send us an email or click on the needed products to send an inquiry.

If you want to know more about Alkali Free Glass Fiber, please feel free and contact us: sales@cabr-concrete.com

Packaging and Storage of Alkali Free Glass Fiber

Packaging: Inner plastic bag 1kg-5kg per small bag, outer woven bag or carton 10kg-25kg per bag, 1200kg per pallet, can also be produced and packaged according to user requirements.

Payment

T/T, Western Union, Paypal, Credit Card etc.

Shipment

By air, by sea, by express, as customers request.

FAQs of Alkali Free Glass Fiber

Q: How is alkali-free glass fiber manufactured?

A: The manufacturing process involves melting the raw materials at high temperatures and then drawing the molten glass into fibers. The process may include additional steps to coat the fibers with a sizing that enhances their handling properties and compatibility with resin systems.

Q: Is alkali-free glass fiber more expensive than regular glass fiber?

A: Generally, alkali-free glass fiber can be more expensive due to the higher quality raw materials used and the specialized manufacturing processes required to achieve the desired properties. However, the increased performance and durability often justify the cost in critical applications.

Q: Can alkali-free glass fiber be recycled?

A: The recyclability of alkali-free glass fiber depends on the specific composition and the condition of the fiber after use. While glass is inherently recyclable, the presence of specialized coatings or the mixed composition may complicate the recycling process. Industrial recycling facilities equipped to handle these materials are available but may not be as widespread as those for standard glass fibers.

Q: What safety considerations should be taken when working with alkali-free glass fiber?

A: Similar to handling regular glass fiber, safety precautions should include:

- Respiratory Protection: Wearing a mask to avoid inhaling dust.

- Eye Protection: Using safety goggles to protect against fiber particles.

- Skin Protection: Wearing gloves and protective clothing to prevent irritation and cuts.

REQUEST A QUOTE

RELATED PRODUCTS

Copper-Coated Microfilament Steel Fiber Fibre for Concrete Use

PP Series Polypropylene Crude Synthetic Fiber High strength Polypropylene Monofilament Fiber

Premium Polyester Fiber For Concrete Use

Polypropylene Monofilament Fiber for Concrete

Shearing Steel Fiber Construction Steel Shearing Type Wave Steel Fiber for Concrete Use