Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

PRODUCT PARAMETERS

Description

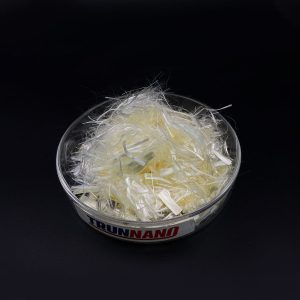

Introduction of Polypropylene Mesh Fiber

Polypropylene mesh fiber is made of polypropylene as raw material through a special process. Its appearance is a mesh structure formed by multiple fiber monofilaments interlaced with each other. When the polypropylene mesh fiber is put into concrete, during the concrete mixing process, the transverse connection between the fiber monofilaments is dispersed by the rubbing and friction of the concrete itself, forming a fully opened fiber monofilament or mesh structure, thereby achieving the effect of a large number of polypropylene fiber concrete. As a new type of concrete reinforcing fiber, polypropylene mesh fiber is becoming a new hot spot in the scientific research and application of fiber concrete after steel fiber and polypropylene monofilament fiber.

Product Function of Polypropylene Mesh Fiber

Improve the impermeability and wear resistance of concrete; improve the reinforcement capacity of concrete; improve the crack resistance of concrete; fire resistance; improve the impact and fatigue resistance of concrete; improve the bending tensile strength and flexural strength of concrete; improve the plastic deformation capacity of concrete, especially high-strength concrete; extremely strong acid and alkali resistance, with good durability.

Parameters of Polypropylene Mesh Fiber

| Density | 0.91g/cm | Shape | Bundle net |

| Equivalent diameter | 100μm | Acid and alkali resistance | ≥95% |

| Length | 12mm、19mm、24mm、30mm、 | Tensile strength | ≥460Mpa |

| Melting point | 160-170℃ | Elastic modulus | ≥4800Mpa |

| Elongation at break | 20±5% | Water absorption | Does not absorb water |

Application of Field Polypropylene Mesh Fiber

1. Projects with high crack resistance requirements such as concrete pavement, bridge deck, airport pavement, factory floor, etc.

2. Engineering projects that use special construction methods such as walls, roofs, and reservoirs of tunnels and mines. When using the spraying process for concrete construction, adding fibers will effectively reduce the rebound rate of the sprayed concrete and reduce pipe friction.

3. Rivers, dams, and other projects.

4. Military protection projects, dock revetments, bridge piers, etc.

Usage of Polypropylene Mesh Fiber

Recommended dosage: 1-2kg/m3, concrete with special requirements can be increased to 5kg/m3.

Mixing process: add aggregate → add fiber → add cement → add water → stir → add water to disperse all the fibers.

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012’s.

We can supply Concrete Fiber over the world. The company has a professional technical department and quality supervision department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.Send us an email or click on the needed products to send an inquiry.

If you want to know more about Polypropylene Mesh Fiber, please feel free and contact us: sales@cabr-concrete.com

Packaging and Storage of Polypropylene Mesh Fiber

Packaging: Inner plastic bag 1kg-3kg per small bag, outer woven bag or carton 10kg-20kg per bag, 500kg per pallet, can also be produced and packaged according to user requirements.

Payment

T/T, Western Union, Paypal, Credit Card etc.

Shipment

By air, by sea, by express, as customers request.

FAQs About Polypropylene Mesh Fiber

- What is Polypropylene Mesh Fiber?

- Answer: Polypropylene mesh fiber is a synthetic fiber made from polypropylene, a thermoplastic polymer. It is commonly used in construction and industrial applications due to its high strength-to-weight ratio, durability, and resistance to chemicals and moisture.

- What are the main uses of Polypropylene Mesh Fiber?

- Answer: Polypropylene mesh fibers are primarily used to reinforce concrete, improving its tensile strength and reducing the risk of cracking. They are also used in geotextiles, erosion control mats, and as a component in various composite materials.

- Why is Polypropylene Mesh Fiber preferred over other materials?

- Answer: Polypropylene mesh fiber is favored for its lightweight nature, excellent chemical resistance, and ability to withstand harsh environmental conditions. It is also cost-effective and easy to handle compared to other reinforcement materials like steel.

- How does Polypropylene Mesh Fiber improve concrete?

- Answer: When added to concrete, polypropylene mesh fibers help to distribute stress more evenly throughout the mixture, thereby enhancing its overall strength and durability. They are particularly effective in reducing micro-cracking, which can lead to structural weaknesses over time.

- Is Polypropylene Mesh Fiber environmentally friendly?

- Answer: Polypropylene mesh fiber is considered relatively environmentally friendly because it is made from a recyclable material and has a long lifespan, reducing the need for frequent replacements. However, proper disposal and recycling practices should be followed to minimize environmental impact.

REQUEST A QUOTE

RELATED PRODUCTS

End Hook Steel Fiber for Concrete Reinforcement Steel Fiber

Wood Cellulose Fibre High Quality High Quality Cellulose Fiber Biodegradable Plant Fiber

Aramid Fiber Aromatic Nylon For Concrete Use

PP Series Polypropylene Crude Synthetic Fiber High strength Polypropylene Monofilament Fiber

High Quality Polypropylene Bundled Fiber For Concrete Using