Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

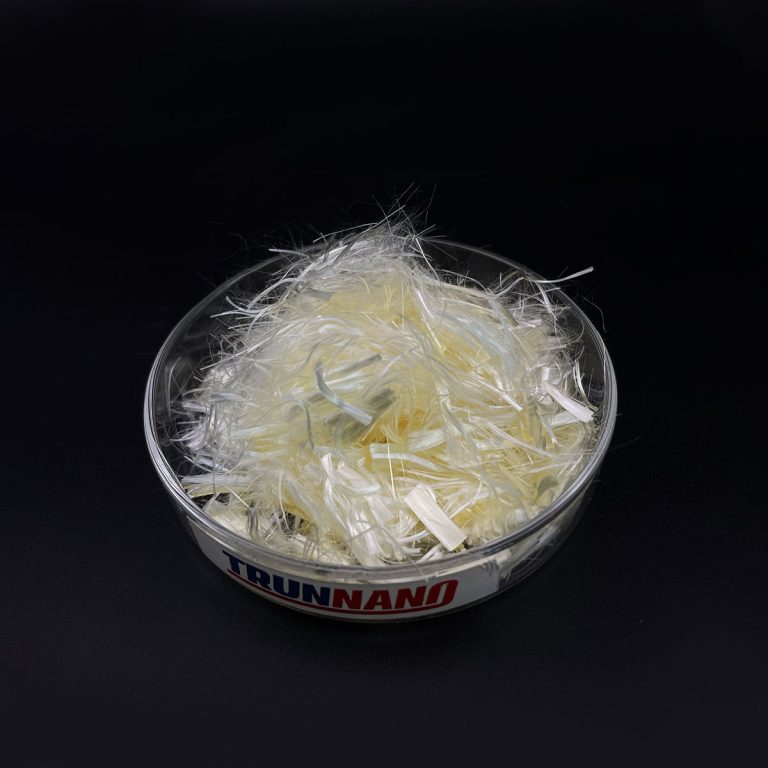

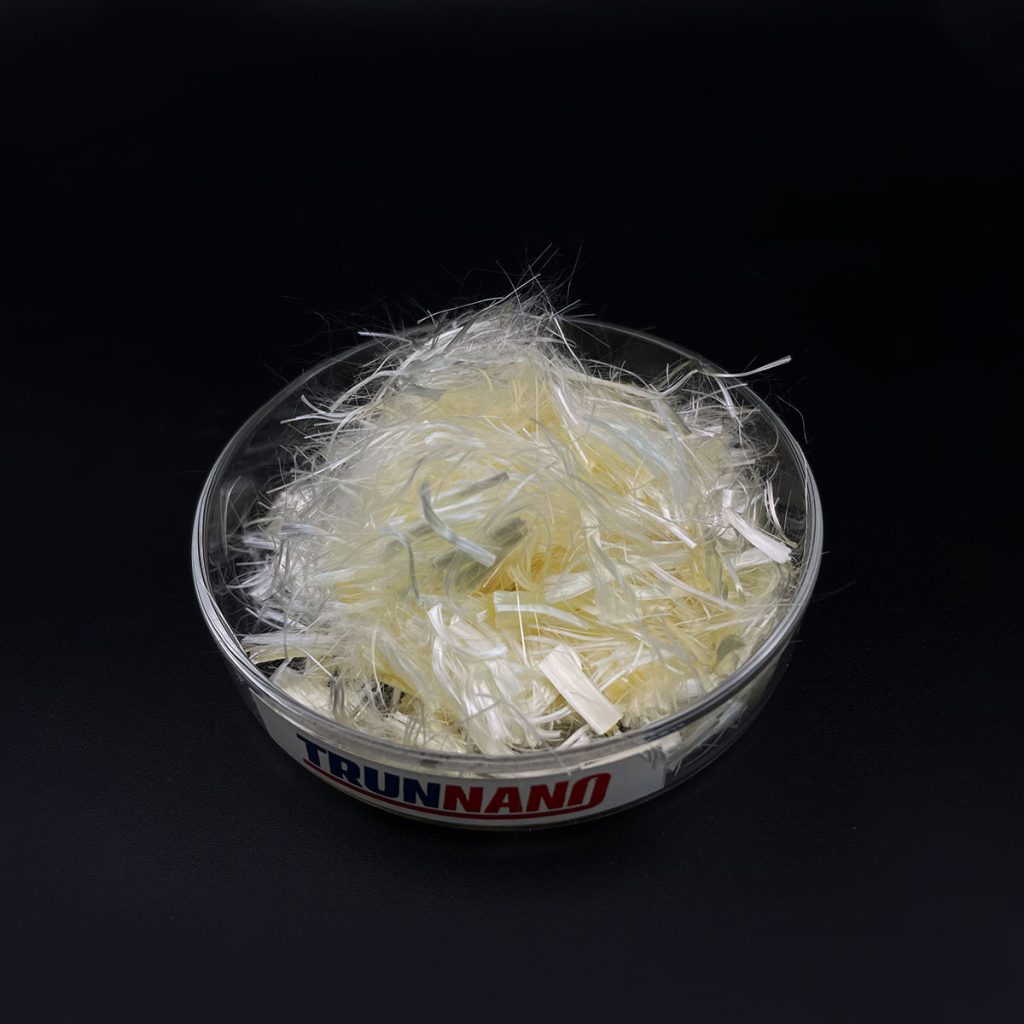

Concrete Fiber

PP Series Polypropylene Crude Synthetic Fiber High strength Polypropylene Monofilament Fiber

PP Series Polypropylene Crude Synthetic Fiber

UHPC Special High Performance Polypropylene Synthetic Fiber

Floor Special Polypropylene Synthetic Stranded High Strength Fiber For Concrete Use

PPF series polypropylene crude synthetic fiber

Floor Special Polypropylene Synthetic Stranded High Strength Fiber

Overview of Concrete Fiber

Concrete fiber is a construction material additive that consists of discrete fibers mixed into concrete to enhance its structural integrity. These fibers can be made from various materials, including steel, glass, synthetic polymers, or natural fibers. When added to concrete, they help improve its tensile strength, impact resistance, and durability.

Features of Concrete Fiber

- Enhanced Durability: Fibers increase the toughness of concrete, making it more resistant to cracking and wear.

- Tensile Strength: They improve the concrete's ability to resist forces that cause stretching or expansion.

- Shrinkage Control: Fibers help control plastic shrinkage cracks that can occur during the drying process.

- Flexural Strength: They contribute to better flexural performance, allowing concrete to bend without breaking.

- Impact Resistance: Fiber-reinforced concrete can withstand greater impact without damage compared to unreinforced concrete.

- Ease of Use: Fibers are typically easy to mix and distribute evenly throughout the concrete mix.

Applications of Concrete Fiber

- Construction: Used in slabs, pavements, bridge decks, and precast elements to increase longevity and reduce maintenance.

- Roads and Highways: Enhances durability and reduces the risk of potholes and rutting.

- Industrial Floors: Provides resistance to heavy loads and impact in warehouses and factories.

- Repair Work: Ideal for overlays and repairs where rapid strength gain and minimal downtime are required.

- Residential Projects: Utilized driveways, patios, and sidewalks to prevent cracking and improve aesthetics.

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012's.

We can supply high-quality Concrete Fiber. The company has a professional technical department and quality supervision department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.Send us an email or click on the needed products to send an inquiry.

If you want to know more about Concrete Fiber, please feel free and contact us: sales@cabr-concrete.com

Package of Concrete Fiber

25Kg woven outer bag lined with plastic bag, stored at room temperature away from light, moisture and rain.

Storage of Concrete Fiber

Paper plastic composite packaging lined with plastic bags.

FAQs of Concrete Fiber

Q: How do fibers improve concrete?

A: Fibers act as internal reinforcement, bridging micro-cracks and improving the overall mechanical properties of the concrete.

Q: Are concrete fibers expensive?

A: The cost varies depending on the type of fiber and quantity needed. Generally, while fibers may add to initial costs, they can reduce long-term expenses through improved durability and fewer repairs.

Q: Can concrete fibers replace rebar?

A: While fibers improve several aspects of concrete performance, they typically do not fully replace traditional rebar in critical load-bearing structures. However, they can often reduce the amount of rebar required.

Q: Are there any environmental concerns with using concrete fibers?

A: The environmental impact depends on the type of fiber used. Synthetic fibers are derived from petrochemicals, whereas natural fibers are biodegradable but may have limited performance. Sustainability considerations should guide the selection of fiber type.

Q: How do I mix concrete fibers?

A: Fibers are generally added directly to the concrete mixer at the specified dosage rate. Proper mixing ensures uniform distribution throughout the concrete. Manufacturer instructions should always be followed.