Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

PRODUCT PARAMETERS

Description

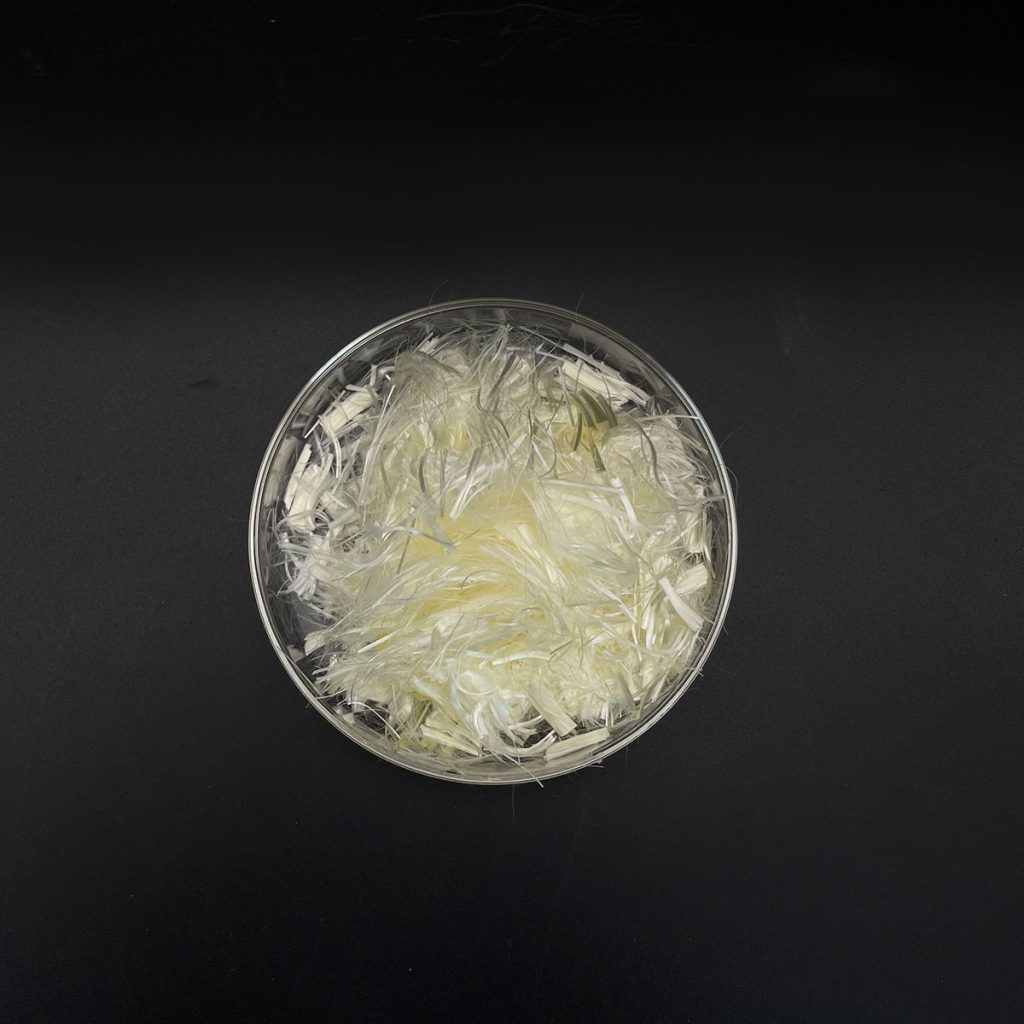

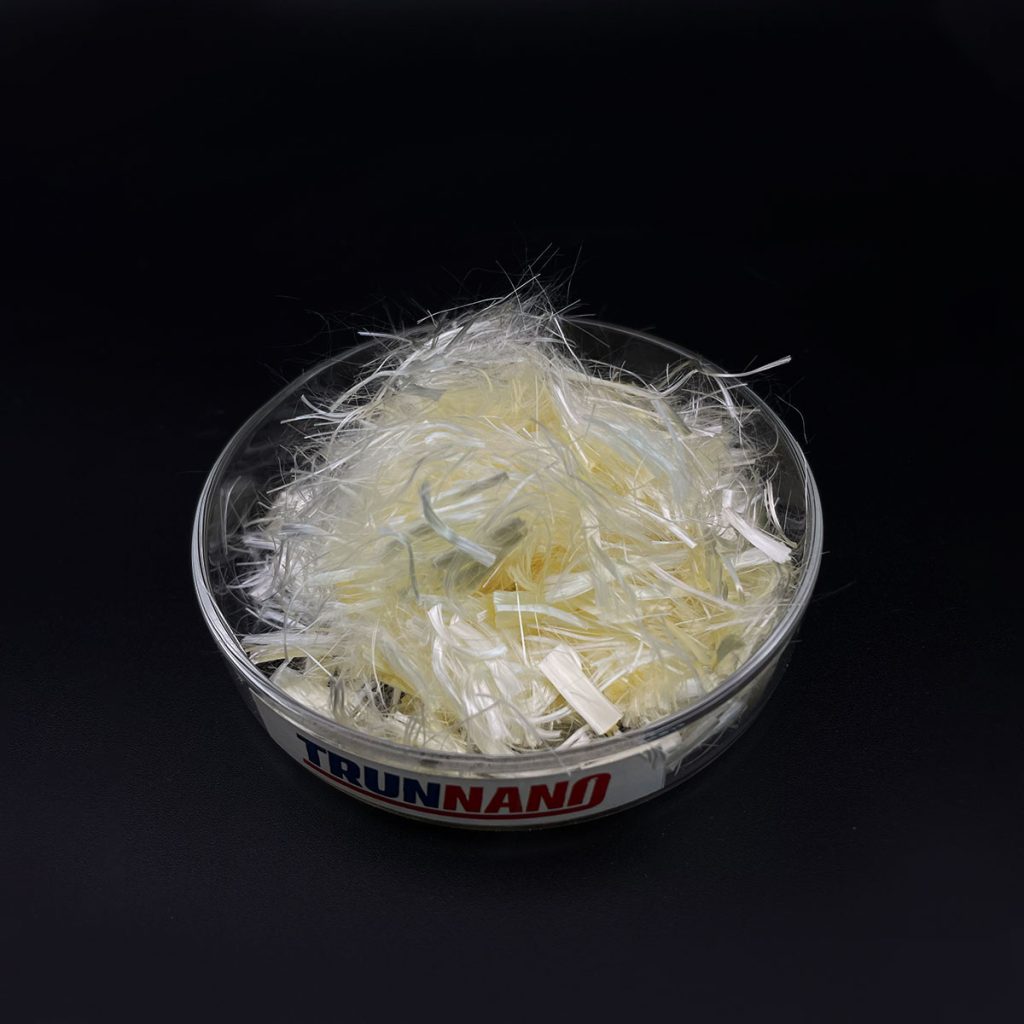

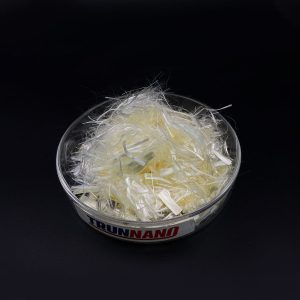

Introduction of Polyacrylonitrile Fiber

As the main reinforcement of cement concrete and asphalt concrete, polyacrylonitrile fiber can significantly increase the tensile strength, fatigue strength and flexural strength of concrete, and significantly improve the early crack resistance of concrete. Polyacrylonitrile fiber used in asphalt can significantly improve the adhesion, high-temperature stability, and fatigue durability of asphalt. Polyacrylonitrile fiber has low-temperature anti-cracking and prevents the occurrence of reflective cracks, effectively improving tensile strength, shear resistance, and fatigue resistance. Compression and impact strength. The real role and application prospects of polyacrylonitrile fiber in concrete have been recognized and accepted by the engineering community.

Function of Polyacrylonitrile Fiber

When polyacrylonitrile fiber is used in cement concrete:

1. Effectively improve the crack resistance of cement concrete.

2. Improve the impermeability and frost resistance of cement concrete, increase durability fiber, greatly reduce the size of capillary pores in concrete and the number of connected capillary pores, effectively improve the frost resistance and impermeability of cement concrete.

3. Reduce the brittleness of concrete, so that the strength of cracked concrete is guaranteed.

4. Improve the wear resistance, tensile strength and toughness of concrete.

5. Improve the impact resistance, earthquake resistance and crack resistance of concrete.

6. Greatly improve the frost resistance of concrete and effectively improve durability.

When polyacrylonitrile fiber is used in asphalt concrete:

1. Improve the dispersion of asphalt concrete mixture.

2. Play the role of reinforcing bar in asphalt mixture.

3. Increase the oil content of asphalt mixture, improve bonding strength and stability.

4. Improve the toughness and low temperature resistance of asphalt mixture.

5. Reduce permanent deformation and improve anti-skid and wear resistance.

6. Reduce the impact of temperature on asphalt pavement and improve the water stability of asphalt pavement.

Usage Method of Polyacrylonitrile Fiber

Construction technical requirements:

Recommended dosage: 0.6-2 kg/m3 for polyacrylonitrile fiber used in cement concrete,

1.5-1.8 kg/m3 for bridge deck pavement and other projects with higher impact resistance requirements.

Mixing time:

According to the amount of fiber added, add it to the prepared sand, stone and cement materials accurately and steadily, add water to the mixer and wet mix for 1 minute. The construction and maintenance of concrete after adding fiber are the same as those without fiber.

Mixing process:

Add aggregate → add fiber → add cement → add water and stir → add water to make the fiber dispersed completely.

Note: When used in asphalt concrete, add the fiber to the aggregate and dry mix it. After 20 seconds, spray it into the asphalt for mixing. The total mixing time is not less than 60 seconds.

Parameters of Polyacrylonitrile Fiber

| Composition | 100%Polyacrylonitrile | Shape | Cylindrical |

| Equivalent diameter | 13-20μm | Color | White or light yellow |

| Length | 0.5mm、3mm、6mm、12mm、19mmCan be customized | Tensile strength | ≥900Mpa |

| Specific gravity | 1.18g/cm3 | Elongation at break | 15±5% |

| Elastic modulus | ≥5500Mpa | Acid and alkali resistance | ≥95% |

| Heat resistance | ≥220℃ | Water absorption | Non-absorbent |

Applications of Polyacrylonitrile Fiber

Polyacrylonitrile fiber is used in cement concrete:

1. Cement products such as concrete precast panels and components.

2. Cement concrete roads, pavements, bridge decks, airport runways, etc.

3. Ports, deep-water docks, bridges and projects in cold regions, etc.

4. Highway anti-collision retaining walls, impact-resistant baffles, etc.

5. Reservoirs, swimming pools, septic tanks, sewage treatment tanks, etc.

6. Panel dams in water conservancy and hydropower projects, etc.

7. Waterproofing projects for structures such as basement side walls, bottom plates, top plates, and roof slabs.

8. Cement mortar, concrete mortar, etc.

Polyacrylonitrile fiber is used in asphalt concrete:

1. New asphalt pavement surface layer, old asphalt pavement cover, etc.

2. Pavement repair, grouting, etc.

3. Steel structure bridge deck paving, etc.

Polyacrylonitrile fiber can also be used as electrostatic flocking fiber, which has good hand feel and thermal insulation performance.

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012’s.

We can supply Concrete Fiber over the world. The company has a professional technical department and quality supervision department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.Send us an email or click on the needed products to send an inquiry.

If you want to know more about Polyacrylonitrile Fiber, please feel free and contact us: sales@cabr-concrete.com

Packaging and Storage of Polyacrylonitrile Fiber

Packaging: Inner plastic bag 0.6kg-2kg per small bag, outer woven bag or carton 10kg-25kg per large bag, 500kg per pallet, can also be produced and packaged according to user requirements.

Payment

T/T, Western Union, Paypal, Credit Card etc.

Shipment

By air, by sea, by express, as customers request.

FAQs of Polyacrylonitrile Fiber

- Is PAN fiber flammable?

- While PAN fiber itself is not highly flammable, it can burn when exposed to high temperatures. However, it tends to char rather than melt, which can limit flame spread.

- Can PAN fiber be recycled?

- Recycling PAN fiber can be challenging due to the chemical processes involved in its production and the difficulty in separating it from other materials. However, there are efforts to develop recycling methods for PAN-based products.

- Is PAN fiber environmentally friendly?

- The environmental impact of PAN fiber depends on how it is manufactured and disposed of. Efforts are being made to improve sustainability in the production process and to find ways to recycle PAN waste.

- How does PAN fiber compare to other synthetic fibers?

- Compared to polyester, nylon, or acrylic, PAN offers better resistance to heat and chemicals. However, it may not be as elastic or as widely used in everyday consumer products as some other synthetics.

- Are there any health concerns associated with PAN fiber?

- Generally, PAN fibers are considered safe for use in textiles and other applications. However, handling the raw materials or dust during production should be done with appropriate safety measures to avoid inhalation or skin irritation.

- What is the difference between PAN fiber and carbon fiber?

- PAN fiber is the precursor to carbon fiber. When PAN fibers are heated to high temperatures in an oxygen-free environment, they become carbon fibers, which are extremely strong and lightweight.

REQUEST A QUOTE

RELATED PRODUCTS

Copper-Coated Microfilament Steel Fiber Fibre for Concrete Use

Alkali Resistant Glass Fiber Reinforced Concrete Chopped Strands

PP Series Polypropylene Crude Synthetic Fiber High strength Polypropylene Monofilament Fiber

Milling Steel Fiber Mill-Cut Hooked Concrete Steel Fiber Concrete Binder Architecturally Acicular Steel Fiber

High Quality Lignin Fiber Organic Fiber for Concrete Use