Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

PRODUCT PARAMETERS

Description

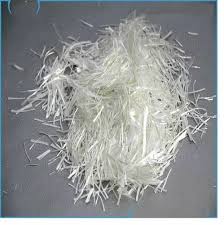

Introduction of Plastic Steel Fiber

Plastic steel fiber, i.e., polypropylene crude fiber, is a substitute product developed for steel fiber, while taking into account some characteristics of synthetic fiber. Compared with steel fiber, it has the characteristics of corrosion resistance, easy dispersion, easy construction, and no damage to mixing equipment. Plastic steel fiber is made of synthetic resin as the main raw material, processed through special processes and surface treatment. It has the advantages of high breaking strength, good dispersion in concrete, strong bond strength, tensile resistance, shear resistance, crack resistance, fatigue resistance, and high toughness. It replaces steel fiber for cement concrete, overcoming the shortcomings of low tensile strength, low ultimate elongation, and brittleness of concrete. Plastic steel fiber has been widely used in engineering fields such as construction, roads and bridges, and hydraulic engineering.

Product Function of Plastic Steel Fiber

1. Adding plastic steel fiber to concrete structure can enhance the tensile strength, shear strength and other mechanical properties of concrete, making it more durable. In addition, plastic steel fiber can also improve the self-cracking resistance, impermeability, impact resistance and other properties of concrete, making it more suitable for engineering construction.

2. Plastic steel fiber is mainly used in the foundation construction of buildings such as roads, tunnels, and bridges. Because plastic steel fiber has the characteristics of high strength, high toughness, and corrosion resistance, it can play an important role in these fields.

3. High tensile strength and strong acid and alkali resistance.

4. Possess the functions of steel bars and steel fibers.

5. Enhance the strength and toughness of UHPC ultra-high performance concrete and improve the performance of UHPC ultra-high performance concrete.

Parameters of Plastic Steel Fiber

| Density | 0.91g/cm | Shape | Cylindrical |

| Equivalent diameter | 0.2-1.5mm | Acid and alkali resistance | ≥95% |

| Length | 30/40/50/60mm Can be customized | Tensile strength | ≥450Mpa |

| Melting point | 160-170℃ | Elastic modulus | ≥5500Mpa |

| Elongation at break | 15±5% | Water absorption | Does not absorb water |

Application Areas of Plastic Steel Fiber

1. Projects with high crack resistance requirements such as concrete pavements, bridge decks, airport runways, and factory floors.

2. Industrial floors such as wear-resistant hardened concrete and diamond floors.

3. Projects using special construction methods for walls, roofs, and reservoirs of tunnels and mines.

4. Bridges, rivers, dams, and other projects.

5. Military protection projects, dock revetments, etc.

6. Make concrete components, pipes, plates, etc.

7. Spraying, pumping concrete, etc.

8. Chemical plants with high requirements for alkali resistance and chemical corrosion, etc.

9. Ultra-high performance concrete, etc.

Usage of Plastic Steel Fiber

Recommended dosage: 3-9kg/m3.

Mixing process: add aggregate → add fiber → add cement → add water → stir → add water to make the fiber dispersed completely.

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012’s.

We can supply Concrete Fiber over the world. The company has a professional technical department and quality supervision department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.Send us an email or click on the needed products to send an inquiry.

If you want to know more about Plastic Steel Fiber, please feel free and contact us: sales@cabr-concrete.com

Packaging and Storage of Plastic Steel Fiber

Packaging: inner plastic bag 1kg-10kg per small bag, outer woven bag or carton 10kg-25kg per bag, 1200kg per pallet, can also be produced and packaged according to user requirements.

Payment

T/T, Western Union, Paypal, Credit Card etc.

Shipment

By air, by sea, by express, as customers request.

FAQs of Plastic Steel Fiber

Can plastic steel fiber be used with other types of reinforcement?

Yes, plastic steel fibers can be used in combination with other reinforcement materials like rebar or mesh. The choice of reinforcement depends on the structural requirements and the desired properties of the concrete.

Are there any specific mixing or curing requirements when using plastic steel fiber?

While plastic steel fiber can be mixed with conventional concrete, it’s important to ensure that the mixing time is adequate to achieve uniform distribution. Curing practices remain the same as with traditional concrete but may be adjusted based on the project’s needs.

How does the cost of plastic steel fiber compare to other reinforcement options?

Plastic steel fiber can be more cost-effective compared to traditional reinforcement methods when considering the overall benefits, such as reduced maintenance and longer service life. However, the initial cost may vary depending on the type and quantity of fiber used.

Are there any environmental benefits to using plastic steel fiber?

Using plastic steel fiber can reduce the need for traditional reinforcement materials, which can lower the environmental impact associated with their production and transportation. Additionally, the increased durability of the concrete can lead to less frequent repairs and replacements.

Is plastic steel fiber suitable for all types of concrete applications?

While plastic steel fiber is highly beneficial for many applications, it’s important to assess the specific needs of the project. Consulting with a structural engineer or concrete professional can help determine if plastic steel fiber is the right choice for a given application.

REQUEST A QUOTE

RELATED PRODUCTS

Chopped Carbon Fiber Products for Concrete Use

UHMWPE Fiber Ultra High Molecular Weight Polyethylene Fiber For Concrete Use

Premium Polyester Fiber For Concrete Use

Polypropylene Monofilament Fiber for Concrete

PVA Fibers for Concrete Reinforcement in a Variety of Concrete Mixes