Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

PRODUCT PARAMETERS

Description

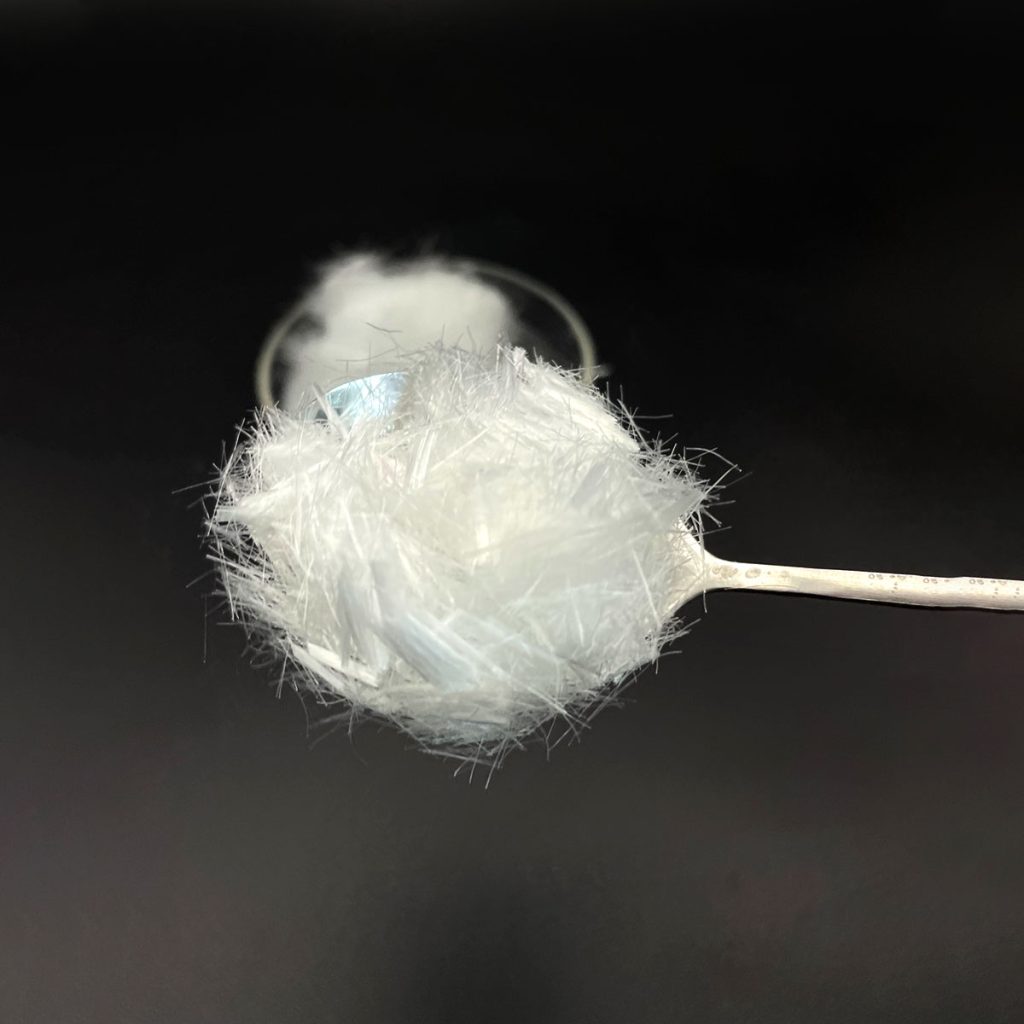

Introduction of PP Series Polypropylene Crude Synthetic Fiber

Basic raw materal: polypropylene

PP (PolyPropylene) series crude synthetic fibers are engineered fibers made from polypropylene, a thermoplastic polymer known for its strength, durability, and resistance to chemicals and moisture. These fibers are designed to be used in a variety of applications, particularly in construction to enhance the performance of concrete and other building materials. They are characterized by their lightweight nature and their ability to improve the tensile strength and crack resistance of concrete, making them a valuable addition to construction projects.

Basic Characteristics of PP Series Polypropylene Crude Synthetic Fiber

1, for all levels of concrete to improve the good anti-fatigue, anti-shrinkage,earthquake grade excellent toughness

2,simple operation, not easy to connect group, safety, high price performance ratio, cost saving;

3. can be used for high strength corrosive, wet environment

4, the surface after embossing treatment, so as to greatly improve the fiber and concrete quality of wrapping grip, but also improve the anti shrinkage, anti crack performance;

5, the strength of crude synthetic fiber is not as good as steel fiber, but the experiment proves that: under the same conditions,each cubic of concrete needs 3kg-9kg crude synthetic fiber, and steel fiber needs 25kg~70kg. The results show that the concrete containing crude synthetic fiber has better toughness and crack resistance.

Parameters of PP Series Polypropylene Crude Synthetic Fiber

| Fiber category | PP series polypropyleneCrude synthetic fibre |

| Tensile strength | 450MPa |

| Modulus of elasticity | 7.5GPa |

| Long degrees | 12~44mm |

| Equivalent diameter | 0.8~1mm |

| Base material | polypropylene |

| Surface treatment | Hank league form |

| Alkali resistance | Very good |

Typical Application Scope of PP Series Polypropylene Crude Synthetic Fiber

Airport apron, bridge tunnel, power station, dam, offshore engineering, mining machine support.

Recommended Dosage of PP Series Polypropylene Crude Synthetic Fiber

Generally 3kg/m*~9kg/m3,the specific dosage depends on the actual application engineering.

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012’s.

We can supply Concrete Fiber over the world. The company has a professional technical department and quality supervision department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.Send us an email or click on the needed products to send an inquiry.

If you want to know more about PP Series Polypropylene Crude Synthetic Fiber, please feel free and contact us: sales@cabr-concrete.com

Packaging and Storage of PP Series Polypropylene Crude Synthetic Fiber

10kg/ bag,11.5kg/ bag, 1 ton: 6-7m,Can be customized according to customer requirements.

Payment

T/T, Western Union, Paypal, Credit Card etc.

Shipment

By air, by sea, by express, as customers request.

FAQs of PP Series Polypropylene Crude Synthetic Fiber

Q: Are PP series fibers easy to incorporate into concrete mixes?

A: Yes, they are relatively easy to incorporate due to their lightweight and non-abrasive nature. Proper mixing techniques ensure even distribution and minimal clumping.

Q: Can PP series fibers be used in extreme environments?

A: Yes, they are suitable for use in environments that are corrosive or subject to high moisture, as polypropylene is resistant to many chemicals and does not corrode.

Q: What is the recommended dosage for PP series fibers in concrete applications?

A: The recommended dosage typically ranges from 3kg/m³ to 9kg/m³, depending on the specific application and desired performance enhancements.

Q: How do PP series fibers affect the workability of concrete?

A: These fibers generally do not adversely affect the workability of concrete; however, proper mixing is essential to maintain consistency and ensure uniform distribution.

Q: Are there any environmental benefits associated with the use of PP series fibers?

A: Yes, the use of polypropylene fibers can lead to a reduction in the overall amount of concrete required, potentially lowering the carbon footprint of construction projects. Additionally, their recyclability contributes to sustainable construction practices.

REQUEST A QUOTE

RELATED PRODUCTS

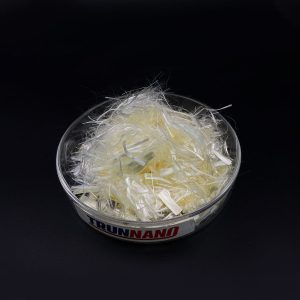

High Quality Fiberglass Chopped Strands Alkali Free Glass Fiber Chopped Strand For Concrete Use

Shearing Steel Fiber Construction Steel Shearing Type Wave Steel Fiber for Concrete Use

Chopped Carbon Fiber Products for Concrete Use

PP Series Polypropylene Crude Synthetic Fiber High strength Polypropylene Monofilament Fiber

Wholesale Price Basalt Fiber High Strength Basalt Fiber Rebar Basalt Fiber Reinforced Composite Rebar For Concrete