Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

PRODUCT PARAMETERS

Description

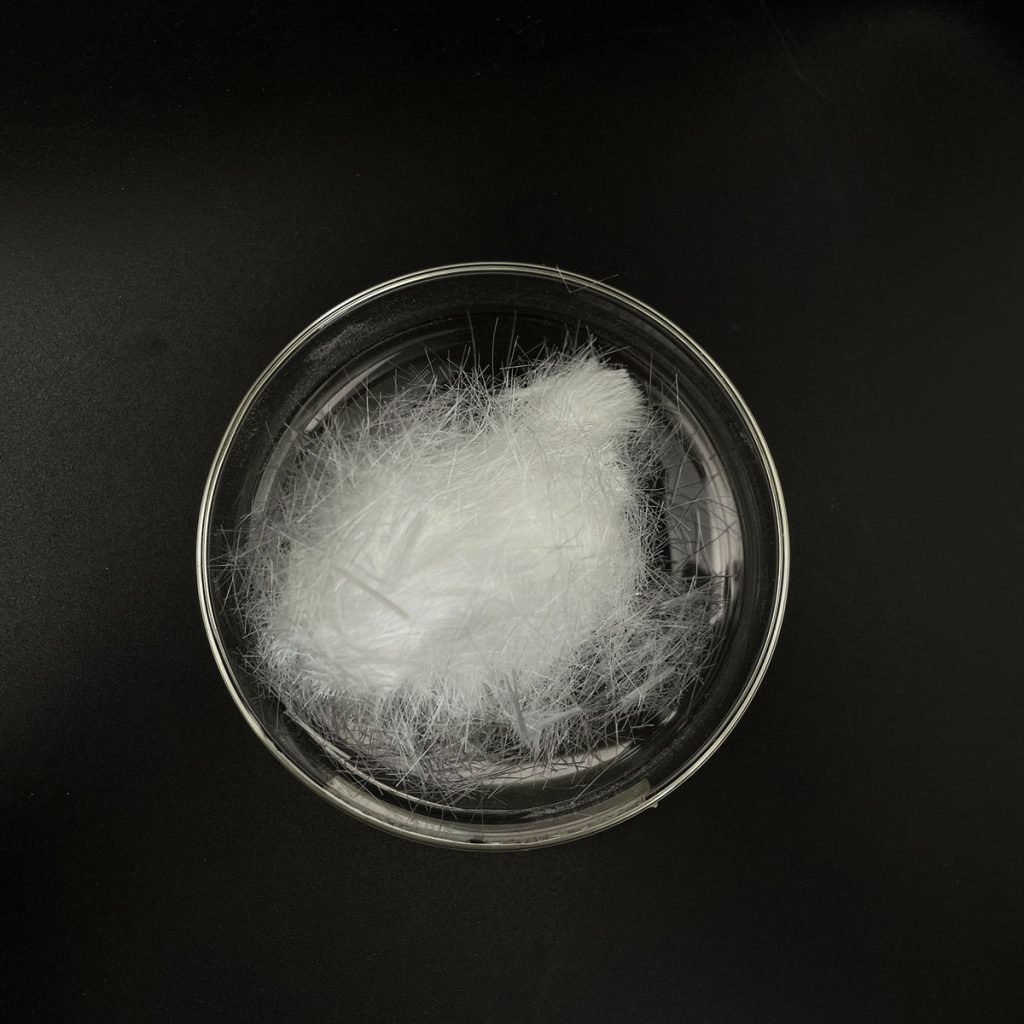

Introduction of PVA Fibers

Polyvinyl alcohol fiber (PVA fiber) is an ideal environmentally friendly cement reinforcement material. Due to its unique molecular structure, it has a good affinity with cement and good alkali resistance and weather resistance. It effectively prevents and inhibits the formation and development of cracks, improves the bending strength, impact strength and crack resistance of concrete, and improves the impact resistance and earthquake resistance of concrete. It can be widely used in the reinforcement of walls, roofs, floors and roads, bridges, tunnels and slopes of industrial and civil buildings. At present, in the cement concrete engineering industry, due to the unique properties of PVA fiber, it has broad development prospects in the fields of engineering and construction applications. It is an ideal new product that can completely replace asbestos.

Function of PVA Fibers

1. Compared with other general organic fibers, polyvinyl alcohol fiber has higher toughness and elastic modulus.

2. The bonding strength between the fiber and the cement matrix is strong. The bonding strength can also be controlled by surface treatment.

3. Its good durability has been proven through long-term field tests, and it has been used as fiber cement slate for more than 20 years because polyvinyl alcohol fiber has been widely recognized as a less dangerous and cost-effective alternative.

Parameters of PVA Fibers

| Item | Data |

| Melting point | >240℃ |

| Tensile strength | ≥1200MPa |

| Elastic modulus | ≥30GPa |

| Elongation at break | ≤15% |

| Length | 4mm、6mm、12mm |

| Diameter equivalent | 2Dtex |

| Alkali resistance | ≥90% |

| Safety | Non-toxic |

Application of PVA Fibers

1. High-strength and high-modulus polyvinyl alcohol fiber is an excellent substitute for asbestos fiber and glass fiber.

2. Large-volume concrete pouring and guardrails, fences, parking lots, etc.

3. Make lightweight wall panels, GRC boards, insulation boards and other building materials, etc.

4. High-strength and high-modulus polyvinyl alcohol fiber can also be used for high-grade road construction, airport runways, factory floors, etc.

5. Shotcrete for tunnels, mines, culverts, etc.

6. Water conservancy and hydropower projects such as docks, river dams, dams, and hydropower stations.

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012’s.

We can supply Concrete Fiber over the world. The company has a professional technical department and quality supervision department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.Send us an email or click on the needed products to send an inquiry.

If you want to know more about PVA Fibers, please feel free and contact us: sales@cabr-concrete.com

Usage Method of PVA Fibers

Recommended dosage: plain slurry or mortar, added amount 0.6-1kg/m3. Concrete added amount 0.6-1.9kg/m3

Mixing process: add aggregate → add fiber → add cement → add water → stir → add water to make all the fibers dispersed.

Payment

T/T, Western Union, Paypal, Credit Card etc.

Shipment

By air, by sea, by express, as customers request.

FAQs of PVA Fiber

- Can PVA fibers be recycled?

- While PVA fibers can degrade in certain environments, recycling them can be challenging due to their chemical properties. However, research is ongoing into methods of recycling these fibers effectively.

- Are there any health or safety concerns associated with PVA fibers?

- PVA fibers are generally considered safe to use; however, like any industrial material, they should be handled according to proper safety guidelines to avoid inhalation or skin irritation.

- What is the typical production process for PVA fibers?

- PVA fibers are produced by dissolving PVA in water, extruding the solution through spinnerets to form fibers, and then washing and drying the fibers to achieve the desired characteristics.

- How do PVA fibers compare to other synthetic fibers like polyester or nylon?

- PVA fibers offer superior chemical resistance and can be more environmentally friendly due to their potential for biodegradability, whereas polyester and nylon are known for their strength and durability but are less likely to biodegrade.

- What are the limitations of using PVA fibers?

- Despite their benefits, PVA fibers can be more expensive compared to traditional reinforcement materials. Additionally, their effectiveness can depend on the specific application and the conditions under which they are used.

- Where can I purchase PVA fibers?

- PVA fibers can typically be purchased from industrial suppliers specializing in construction materials or from companies that produce synthetic fibers for various applications.

REQUEST A QUOTE

RELATED PRODUCTS

High Quality Polypropylene Mesh Fiber For Concrete Use

Copper-Coated Microfilament Steel Fiber Fibre for Concrete Use

UHPC Special High Performance Polypropylene Synthetic Fiber

Floor Special Polypropylene Synthetic Stranded High Strength Fiber For Concrete Use

PPF series polypropylene crude synthetic fiber