Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

PRODUCT PARAMETERS

Description

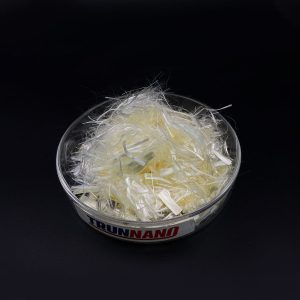

Introduction of Shearing Steel Fiber

Sheared steel fiber is a fiber cut from thin steel plates or steel strips. The overall surface is wavy and the cross section is rectangular.

Function of Shearing Steel Fiber

1. Excellent wear resistance and durability, higher fatigue endurance limit.

2. High ductility and impact resistance.

3. Good dispersion, steel fiber will not ball up in concrete and is evenly distributed.

4. Improve the tensile, bending and shearing mechanical properties of concrete.

5. The rough and clean surface of steel fiber can be firmly combined with the cement paste in concrete.

6. Compared with traditional reinforced concrete, steel fiber concrete is directly constructed and seamlessly connected to large laser leveling equipment, saving costs.

6. The construction process is simpler, and the construction period is greatly shortened compared to the steel bar scheme.

Application Field of Shearing Steel Fiber

1. Construction engineering: house construction, prefabricated piles, frame nodes, roof waterproofing, underground waterproofing, etc.

2. Industrial floor: cut-slit floor, no-slit floor, seamless floor, pile-supported floor, garage leveling layer, composite floor slab, raft, factory road, pavement, etc.

2. Pipeline engineering: centrifugal tube, vibration and extrusion tube, pump tube, steel-lined steel fiber concrete pressure tube, etc.

3. Highway bridge engineering: box arch bridge arch ring, continuous box beam, bridge deck, etc.

4. Highway pavement and airport bridge deck engineering: highway pavement, highway pavement in frozen areas, airport pavement, etc.

5. Railway engineering: prestressed railway sleepers, double-block railway sleepers, etc.

6. Water conservancy and hydropower engineering: water flow erosion wear parts, gates, gate canals, ferry canals, dam anti-seepage panels, etc.

7. Port and marine engineering: steel pipe pile anti-corrosion layer, dock facilities, submarine concrete facilities, etc.

8. Other projects: heavy-duty industrial sites/warehouse floors, silos, maintenance and reinforcement projects, underground cables, pipe manhole covers, sewer grates, etc.

Usage of Shearing Steel Fiber

Construction technical requirements:

1. The cement grade shall not be lower than 425. The water-cement ratio shall not be greater than 0.5.

2. The diameter length of the coarse aggregate shall not exceed 2/3 of the length of the steel fiber.

3. The volume of steel fiber in steel fiber concrete shall not be less than 0.5%, generally between 0.5-3%, and 1.5%–2.5% is recommended; that is, the dosage range per cubic meter of concrete is: 5-30kg, and 15-25kg is recommended.

4. Sea sand shall not be used in mixing steel fiber concrete, and chloride salt is strictly prohibited.

5. In addition to the above provisions, other materials used in steel fiber concrete shall comply with the provisions on raw materials used in reinforced concrete in the current specifications.

6. The consistency of steel fiber concrete can be determined by referring to the consistency required for ordinary concrete in similar projects. Its slump value can be smaller than the required value of the corresponding ordinary concrete.

7. When the steel fiber concrete cushion layer and surface layer with flat-head joint structure has no foundation reinforcement layer such as ash soil under the cushion layer and meets the following conditions at the same time:

a. The thickness of the pre-potential layer and surface layer before reduction is not more than 130mm.

b. The thickness of the foundation reinforcement layer is greater than the thickness of the cushion layer. Its thickness can be multiplied by the reduction factor 0.75, but shall not be less than 50mm

Material discharge requirements:

Steel fiber and coarse aggregate – stir for 30 seconds – add sand and cement → stir for 30 seconds – add water → stir for 3 minutes

Compacting:

1. When pouring steel fiber concrete, mix and use it, pour continuously, and do not throw away the construction joints until the partition joints are reached. It should be vibrated and compacted during pouring.

2. Surface finishing. Embossed steel fiber concrete has the characteristics of fine coarse aggregate, large sand rate, and random fiber distribution. It is smoothed mechanically to prevent fiber exposure. The embossing process using an embossing machine can also avoid the phenomenon of fiber exposure caused by pulling. After 24 hours, it should be maintained in time according to the routine. It should be covered with straw bags in summer and keep warm in winter.

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012’s.

We can supply Concrete Fiber over the world. The company has a professional technical department and quality supervision department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.Send us an email or click on the needed products to send an inquiry.

If you want to know more about Shearing Steel Fiber, please feel free and contact us: sales@cabr-concrete.com

Packaging and Storage of Shearing Steel Fiber

Packaging: Carton or composite packaging paper bag 25kg/box or bag, 1500kg-2000kg per pallet, and can also be produced and packaged according to user requirements.

Payment

T/T, Western Union, Paypal, Credit Card etc.

Shipment

By air, by sea, by express, as customers request.

FAQs of Shear Steel Fiber

How Are Milling Shear Steel Fibres Used?

These fibres are typically mixed into the concrete during the batching process. They are uniformly distributed throughout the wet concrete mix before it hardens. The addition of steel fibers does not change the basic composition of the concrete but enhances its mechanical properties.

Can Milling Shear Steel Fibres Replace Conventional Rebar?

While milling shear steel fibres provide significant reinforcement benefits, they are not usually intended to replace traditional rebar entirely. In certain applications, such as thin sections or areas where rebar placement is difficult, fibers can be used to supplement or partially replace conventional rebar.

Are There Any Challenges When Using Milling Shear Steel Fibres?

Yes, there are a few challenges:

- Mix Design: Achieving the right balance of fiber content and concrete mix design can be complex.

- Placement: Proper placement and distribution of the fibers are crucial for performance.

- Pumpability: High fiber content can affect the pumpability of the concrete.

- Cost: Steel fibers can be more expensive than traditional reinforcements.

How Do You Ensure Proper Distribution of Fibers in Concrete?

To ensure proper distribution, it’s important to follow manufacturer guidelines regarding the mixing time and the use of appropriate mixing equipment. Agitation and adequate mixing time are essential to avoid clumping and ensure an even distribution of fibers.

What Types of Projects Benefit Most from Milling Shear Steel Fibres?

Projects that benefit most from the use of milling shear steel fibres include:

- Slabs-on-grade where reducing cracking is critical.

- Bridge decks and other structures exposed to heavy traffic and weather conditions.

- Industrial floors requiring high wear resistance.

- Repair and overlay projects where rapid curing and early strength gain are advantageous.

REQUEST A QUOTE

RELATED PRODUCTS

UHMWPE Fiber Ultra High Molecular Weight Polyethylene Fiber For Concrete Use

PP Series Polypropylene Crude Synthetic Fiber High strength Polypropylene Monofilament Fiber

Wood Cellulose Fibre High Quality High Quality Cellulose Fiber Biodegradable Plant Fiber

Floor Special Polypropylene Synthetic Stranded High Strength Fiber For Concrete Use

Milling Steel Fiber Mill-Cut Hooked Concrete Steel Fiber Concrete Binder Architecturally Acicular Steel Fiber