Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

PRODUCT PARAMETERS

Description

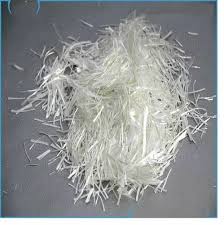

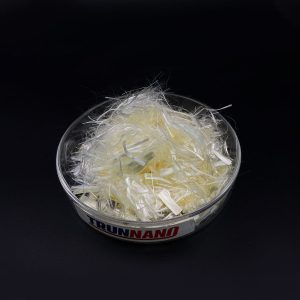

Introduction of UHPC Special High Performance Polypropylene Synthetic Fiber

Basic raw material: polypropylene

Ultra-High Performance Concrete (UHPC) special high performance polypropylene synthetic fibers are advanced materials designed to enhance the mechanical properties of UHPC, a type of concrete known for its exceptional strength, durability, and tight microstructure. These fibers are typically made from polypropylene, a thermoplastic polymer chosen for its strength, chemical resistance, and low density. When incorporated into UHPC, these fibers aim to improve the material’s tensile strength, reduce the risk of cracking, and enhance its overall performance under various stress conditions.

Basic Characteristics of UHPC Special High Performance Polypropylene Synthetic Fiber

Although UHPC can achieve high compressive strength, the flexural strength of UHPC is mainly used for thin building components. in practical applications, the basic ultra-high strength of UHPC is further enhanced and toughened by a small amount of copper coated fiber, a specialty synthetic fiber.

UHPC special synthetic fiber using hydrophilic modification technology for surface treatment, has excellent dispersion in UHPC, and has good bonding performance with cement basic materials, can effectively reduce the inhibition of UHPC plastic shrinkage, drying shrinkage, temperature changes caused by factors such as micro cracks, The cracking resistance, toughness, impact resistance and fire-proof ability of UHPC can be significantly improved.

Parameters of UHPC Special High Performance Polypropylene Synthetic Fiber

| Fiber category | UHPC special high performancePolypropylene synthetic fibre |

| Tensile strength | 550MPa |

| Modulus of elasticity | 8.5GPa |

| Long degrees | 12~20mm |

| Equivalent diameter | 0.2mm |

| Base material | polypropylene |

| Surface treatment | Hank league form |

| Alkali resistance | Very good |

Typical Application Scope of UHPC Special High Performance Polypropylene Synthetic Fiber

HUPC art production,UHPC curtain wall,UHPC long span bridge,UHPC external wall art

Recommended Dosage of UHPC Special High Performance Polypropylene Synthetic Fiber

1, dosage: commonly used dosage of 5kg/m~30kg/m³ (corresponding volume dosage of 0.1%~4%);

2, stirring: UHPC powder and water mixing evenly after the pulp. add fiber, stirring 3~5min, to evenly dispersed fiber is the best;

3. Maintenance. the construction and maintenance process of UHPC after adding fiber is exactly the same as that of the system without fiber.

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012’s.

We can supply Concrete Fiber over the world. The company has a professional technical department and quality supervision department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.Send us an email or click on the needed products to send an inquiry.

If you want to know more about UHPC Special High Performance Polypropylene Synthetic Fiber, please feel free and contact us: sales@cabr-concrete.com

Packaging and Storage of UHPC Special High Performance Polypropylene Synthetic Fiber

10kg/ bag, 1 ton: 7m, Can be customized according to customer requirements.

Payment

T/T, Western Union, Paypal, Credit Card etc.

Shipment

By air, by sea, by express, as customers request.

FAQs of UHPC Special High Performance Polypropylene Synthetic Fiber

Q: How do you ensure proper dispersion of the fibers in the UHPC mix?

A: Proper dispersion is crucial. Adequate mixing equipment and techniques must be employed to ensure the fibers are evenly distributed throughout the mix, avoiding clumping or bridging.

Q: What is the typical dosage range for these fibers in UHPC?

A: The dosage typically ranges from 0.5% to 3% by volume of the UHPC mix, but the exact amount depends on the specific project needs and the desired performance outcomes.

Q: Can these fibers be used in conjunction with other admixtures or reinforcements?

A: Yes, they can be used alongside other admixtures and reinforcements, such as silica fume or microsilica, to achieve optimized performance. Compatibility should be tested to ensure there are no adverse interactions.

Q: Are there any environmental advantages to using these fibers?

A: Yes, using polypropylene fibers can contribute to more sustainable construction practices. They can reduce the total amount of concrete needed and extend the life of the concrete structures, thereby minimizing waste and reducing the carbon footprint.

Q: How do these fibers affect the setting time of UHPC?

A: Generally, these fibers do not significantly affect the setting time of UHPC. However, the presence of fibers might influence the fresh properties of the mix, such as viscosity, which can be managed through proper mixing techniques.

REQUEST A QUOTE

RELATED PRODUCTS

PP Series Polypropylene Crude Synthetic Fiber High strength Polypropylene Monofilament Fiber

Chopped Carbon Fiber Products for Concrete Use

Polypropylene Monofilament Fiber for Concrete

Premium Polyester Fiber For Concrete Use

High Quality Fiberglass Chopped Strands Alkali Free Glass Fiber Chopped Strand For Concrete Use