Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

PRODUCT PARAMETERS

Description

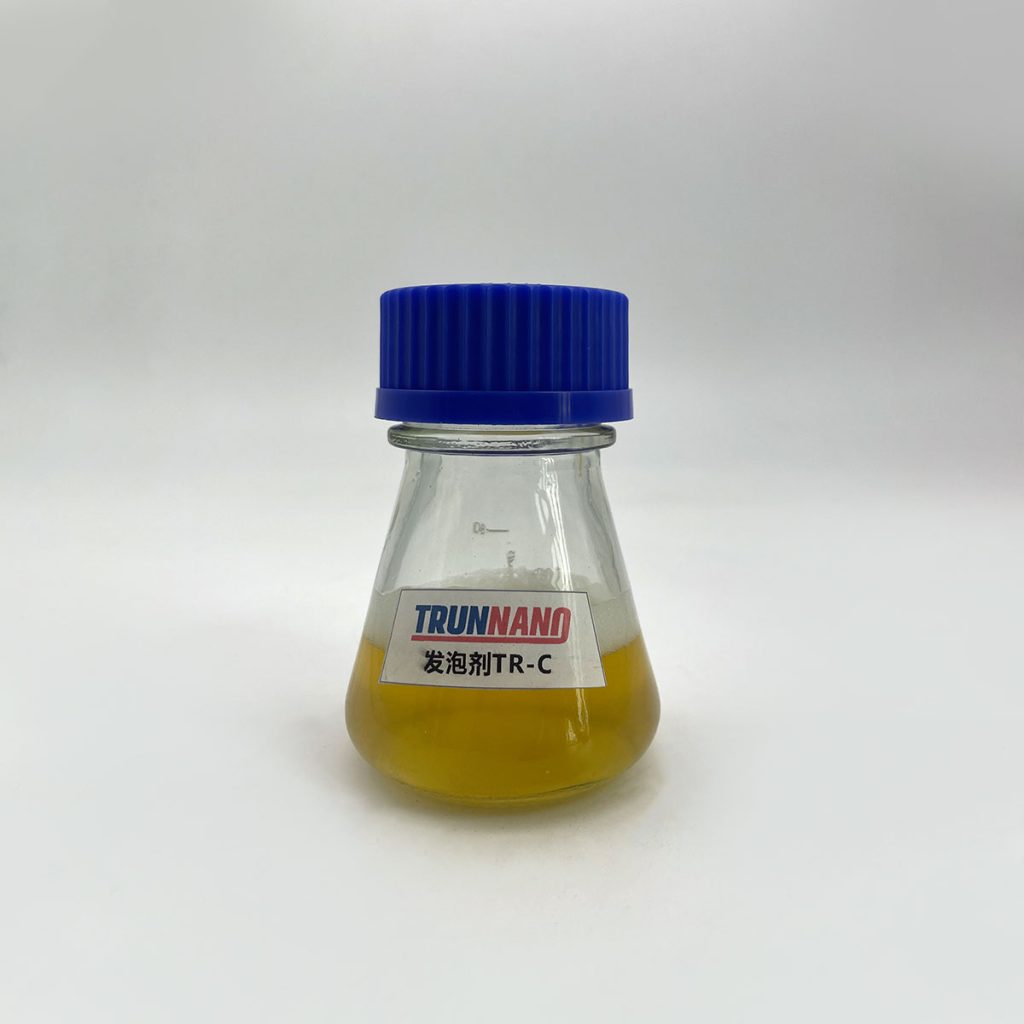

Overview of TR-C Polymer Foaming Agent

Luoyang Tongrun developed TR-C polymer concrete foaming agent to meet the performance requirements of foamed wallboards and CLC blocks.

TR-C polymer foaming agent can satisfy the compressive strength, thermal conductivity, and stability of foamed wallboard.

TR-C polymer foaming agent is especially suitable for foamed wallboard, polystyrene particle-foamed cement wallboard, and other foamed wallboard products, CLC blocks.

Compared with the industry standard, the stability and foaming ratio of the TR-C foaming agent are greatly improved.

Parameters of TR-C Polymer Foaming Agent

| Item | Test Results |

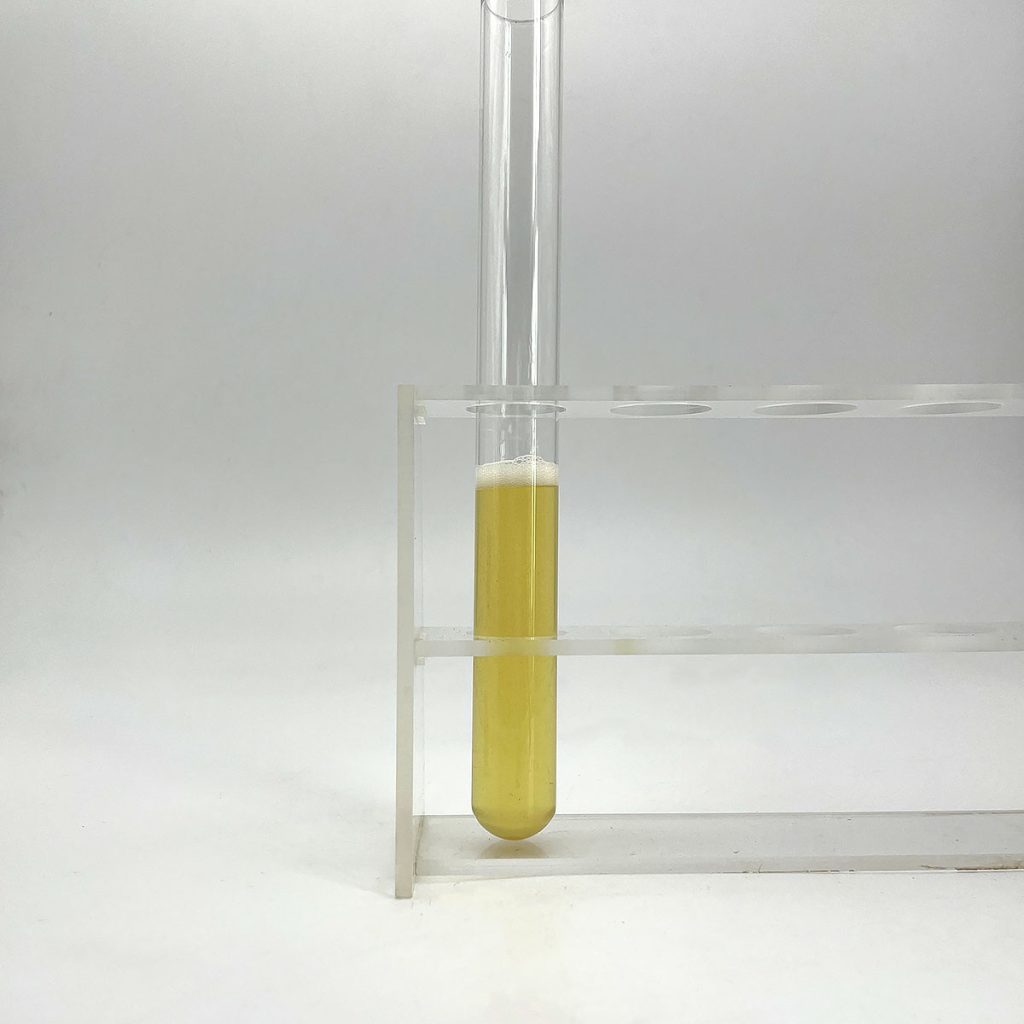

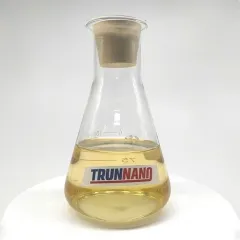

| Appearance | Light yellow and transparent |

| Density(g/mL) | 1.01 |

| Foaming multiple | 26 |

| Settlement distance(mm) | 30 |

| pH | 8.0-9.5 |

| Dilution ratio | 1:30 |

| Operating temperature (℃) | -10-40 |

Features of TR-C Polymer Foaming Agent

1) Increase the strength of the wallboard by 20%

Because of its high foam toughness, the foam wallboard made of foamed wallboard has high cell integrity, closed cell ratio of more than 90%, and spherical thin shell structure, which increases the strength of foamed concrete by more than 20% compared with foam concrete with connected foam cells.

To achieve the same design strength, foam concrete with a high closed-cell ratio can reduce density and save 10% of raw material cost.

2) To improve the thermal insulation performance of wallboards and other products

The foam wallboard made of the foaming agent has extremely high cell integrity, and the cell closure rate is more than 90%. Hundreds of millions of closed pores are formed inside the wallboard, which can seal a large amount of air, form an inert heat conduction layer, and improve the thermal insulation performance of the wallboard.

At the same time, because it has higher strength than other foamed cement with the same density when it reaches the same strength, it can reduce the density of foam concrete, thus reducing the cost and improving the performance of thermal insulation.

3) High stability

TR-C polymer foaming agent is composed of a high-performance foam stabilizer and surfactant. The foam stability is remarkable. In the wallboard production process, the foam paste stability is high, there is no mold collapse phenomenon, the foaming and workability are good, and it can fill the mold without leaving a dead corner.

Instructions for TR-C Polymer Foaming Agent

1) Dilute in advance in the proportion of 1 part of the foaming agent: 30-40 parts of water.

2) When the appropriate amount of foam is injected according to the bulk density requirement, and the mixture is evenly mixed, the production of foam concrete is completed.

3) The foaming agent should add 0.8-1kg foaming agent stock solution per cubic foam concrete product.

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012’s.

We can supply high-quality Concrete Foaming Agent such as Polymer Cellular Lightweight Concrete Foaming Agent, TR-C Polymer Foaming Agent,TR-A Concrete Foaming Agent all over the world.

The company has a professional technical department and quality supervision department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.Send us an email or click on the needed products to send an inquiry: sales@cabr-concrete.com

Package of TR-C Polymer Foaming Agent

25kg/barrel, 200kg/barrel, IBC tank

Storage Method of TR-C Polymer Foaming Agent

The polymer foaming agent should be sealed and stored in a cool, ventilated warehouse.

If it is exposed to direct sunlight or high temperature for a long time, it will easily cause deterioration.

FAQs of TR-C Polymer Foaming Agent

Can TR-C be used in extreme temperatures?

Yes, TR-C can operate effectively within a temperature range of -10°C to 40°C, making it suitable for various climatic conditions during construction.

How do I prepare TR-C for use?

Dilute the foaming agent in water at a ratio of 1 part foaming agent to 30-40 parts water before use. Add 0.8-1 kg of the diluted solution per cubic meter of foam concrete product.

What benefits does using TR-C provide in terms of cost?

By increasing the closed-cell ratio and strength, TR-C allows for a reduction in the density of foam concrete, which can lead to a 10% savings on raw material costs while maintaining or improving performance.

Is TR-C easy to work with during the manufacturing process?

Yes, TR-C provides excellent foam stability and workability, ensuring that the foam paste does not collapse and can fill molds completely, without leaving any voids.