Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

PRODUCT PARAMETERS

Description

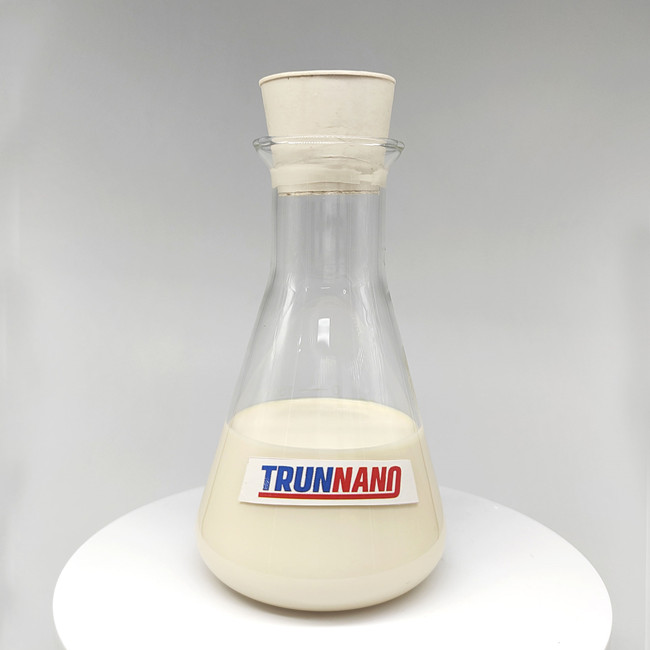

Overview of Water-based Concrete Release Agent

Concrete release agent TR-W is also called concrete release agent or release agent. It is a material coated inside the formwork for lubrication and isolation so that the concrete can be separated from the formwork smoothly when the formwork is removed, and the shape of the concrete remains unchanged.

Water-based Concrete Release Agent is suitable for aluminum, steel, resin, ABS plastic molds, wood, and other materials to mold concrete formwork.

Mechanism of action:

Isolation effect: creates a lubricating film between the formwork and the concrete, making it easy to detach the concrete from the formwork.

Protection of formwork: reduces wear and tear on the formwork and extends its service life.

Improvement of surface quality: helps to keep the surface of the concrete smooth and free of defects, improving aesthetics.

Parameters of Water-based Concrete Release Agent

| Appearance | Liquid |

| Density(g/cm3) | 0.95-0.97 |

| pH | 8.0-9.0 |

| stability | The product has no stratification |

| corrosivity | No corrosion to the template |

| Film forming time | 30-60 minutes (subject to the full drying of the painted surface) |

| Dosage (per kilogram of stock solution) | 100-150 m2/kg |

Improvement of surface quality: helps to keep the surface of the concrete smooth and free of defects, improving aesthetics.

Feature of Water-based Concrete Release Agent

1. Aqueous polymer composite concentrated material through the unique formula milling and processing of environmentally friendly products.

2. Excellent isolation performance and easy disassembly.

3. Quickly into the model, resist water scour, and protect the mold.

4. Concrete surface is clean, smooth and has no pollution.

5. Protection, prolong the service life of the mold.

Application Scenarios of Water-based Concrete Release Agents

Cast-in-place concrete structures: used for foundations, columns, walls, beams and other parts of buildings to ensure a smooth concrete surface after mold removal.

Precast concrete components, such as floor slabs, staircases, railings, etc., facilitate efficient production and high-quality finished products.

Decorative concrete products, such as pavement blocks, landscape stones, and antique building components, maintain the integrity of fine textures and patterns.

Bridges and tunnels: providing good release properties while protecting the formwork from corrosion.

Method of use

1)Preparation: Make sure the surface of the formwork is clean, dry and free from dust, grease or other contaminants.

2) Dilution ratio: Dilute with water according to the ratio recommended in the product manual (usually between 1:3 and 1:5) to achieve the best application effect.

3) Method of application: It can be applied evenly to the surface of the formwork by brushing, rolling or spraying to ensure full coverage.

4) Drying time: Allow sufficient time for the release agent to dry fully, it is generally recommended to wait at least 30 minutes to 1 hour before pouring concrete.

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012’s.

We can supply high-quality concrete additives such as Potassium Silicate, Gypsum retarder and enhancer, Polyvinyl Alcohol Fiber, Concrete Crack Reducing Admixture, Hollow Glass Microspheres, Concrete strength and shrinkage reducer, Waterproof agent, Redispersible Polymer Powder (RDP) all over the world.

The company has a professional technical department and quality supervision department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.Send us an email or click on the needed products to send an inquiry: sales@cabr-concrete.com

Package of Water-based Concrete Release Agent

20 kg/barrel, 200 kg/barrel, IBC Tank

Payment

T/T, Western Union, Paypal, Credit Card etc.

Shipment

By air, by sea, by express, as customers request.

FAQs of Water-based Concrete Release Agent

Q1

What is the principle of water-based concrete release agent?

Answer:

The principle of water-based concrete release agent is to use the adsorption, adhesion and isolation properties of its polymer to isolate the concrete and the mold surface, thereby preventing concrete adhesion and damage during the demoulding process.

Q2

How to choose a suitable water-based concrete release agent?

Answer:

Choosing a suitable water-based concrete release agent requires consideration of multiple factors, such as product quality, brand reputation, performance parameters, usage scenarios, and safety. It is recommended to choose regular brands and channels to purchase, understand the product’s performance parameters and usage methods, and choose the appropriate product based on actual needs.

Q3

What should you pay attention to when using water-based concrete release agent?

Answer:

When using water-based concrete release agents, you need to pay attention to the following points: first, you need to keep the surface of the formwork clean and dry to avoid oil, moisture and other impurities; secondly, you need to choose a suitable water-based concrete release agent according to the actual situation, and use it correctly according to the instructions ; Pay attention to safety during use and avoid inhaling mist and contact with skin; finally, avoid collision and extrusion during storage and transportation.

Q4

Will water-based concrete release agents affect the strength and durability of concrete?

Answer:

Water-based concrete release agents do not affect the strength and durability of concrete. Because water-based concrete release agent is only a surface treatment agent, its function is to prevent concrete adhesion and damage, and will not change the internal structure and performance of concrete.

Q5

Can water-based concrete release agents be reused?

Answer:

Water-based concrete release agents can be reused. During use, care must be taken to keep it clean and dry, and to avoid the mixing of impurities and oil to ensure its performance and service life. If you find that the release agent precipitates or crystallizes, you can continue to use it after stirring evenly. However, it should be noted that if the release agent has expired or is seriously contaminated, it should be discarded and no longer used.

Q6

What is the price of water-based concrete release agent?

Answer:

The price of water-based concrete release agents varies depending on factors such as brand, quality and performance parameters. Generally speaking, water-based concrete release agents are more expensive than oil-based concrete release agents, but they have higher cost performance and use value. When purchasing, you can choose the appropriate product based on actual needs. Don’t blindly pursue low prices and ignore the quality and use effects of the product.