Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

Foaming Equipment

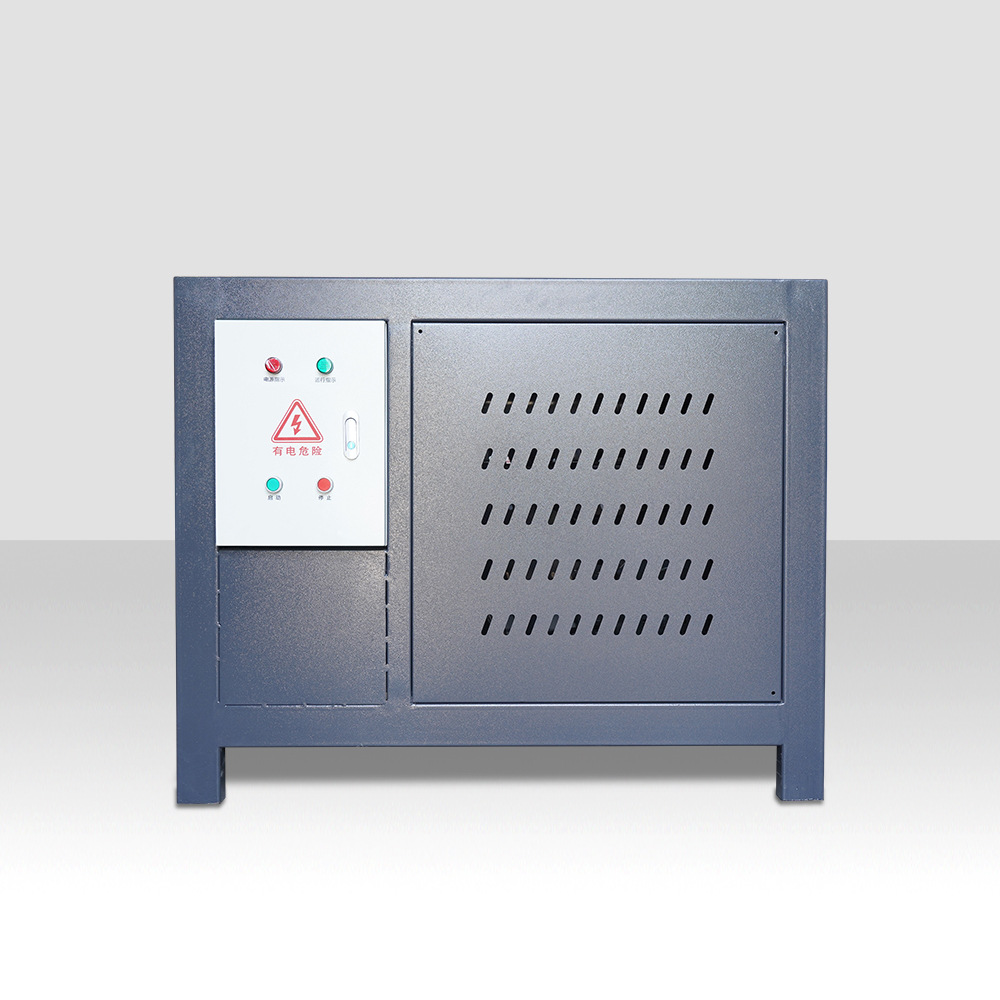

industrial design Equipment for making foam Foaming machine

industrial design Equipment for making foam Foaming machine

industrial design Equipment for making foam Foaming machine

Integrated Machine for Pouring Light Steel Keel and Structural Wall

TR-40 Foam Concrete Blocks Making Machine

TR-20 Lightweight Concrete Machine

Foam Concrete Horizontal Mixer 300L 750L

Foam Concrete Mixer Small Concrete Machine Mixer

Polycarboxylate Superplasticizer Container Equipment

TR30 CLC Foaming Machine Concrete Foam Generator

TR75 7.5 kW CLC Foam Generator for Lightweight Concrete

13kw High Expansion Foam Generator

Overview of Concrete Foaming Equipment

Foaming equipment, additionally known as foam generator, makes foam from a liquid solution containing a specific focus of frothing representative. Foam generator is a vital tools for producing lathered cement and foam-mixed dirt, directly affecting lightweight concrete's high quality and performance. TRUNNANO collection foam generator all utilize high-pressure air foaming, which has the advantages of fast frothing rate, high effectiveness, little bubble diameter, great foam security, low foam secretion and conserving lathering agent.

Features of Concrete Foaming Equipment

It can precisely manage the density and top quality of the foam, making certain that the generated foam concrete has an uniform circulation of bubbles, which not only enhances the thermal insulation efficiency of the product, but likewise boosts the architectural strength. Second of all, the equipment is very easy to run and has a high level of automation, which greatly lowers labor prices and labor intensity, while enhancing job effectiveness. Moreover, given that the foaming proportion can be readjusted, it is suitable for a range of building needs, from wall surface loading to roofing system insulation, with strong adaptability. Furthermore, using concrete frothing makers can effectively minimize the quantity of concrete used and decrease carbon discharges, which is in line with the advancement trend of eco-friendly structures. This machine is normally outfitted with an advanced mixing system to guarantee the complete blending of the combination, avoid stratification, and additionally guarantee the top quality of the project.

Applications of Concrete Foaming Equipment

- Building and construction: Made use of in the development of lightweight concrete blocks, floorings, and wall surfaces, giving better insulation and soundproofing.

- Backfilling: Suitable for backfilling trenches and around pipelines, minimizing hydrostatic pressure and soil activity.

- Gap Filling Up: Ideal for filling tooth cavities and voids where typical concrete might be too hefty or not practical.

- Roofing and Flooring: Utilized in roofing applications to add insulation and in floor covering to enhance audio dampening.

- Bridge Building: For bridge decks and various other applications where weight reduction is vital for architectural stability.

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012's.

We can supply high-quality Foaming Equuipment. The company has a professional technical department and quality supervision department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.Send us an email or click on the needed products to send an inquiry.

If you want to know more about Concrete Foaming Equipment, please feel free and contact us: sales@cabr-concrete.com

Package of Concrete Foaming Equipment

Customised packaging, stored at room temperature away from light, moisture and rain.

FAQs of Concrete Foaming Equipment

Q: What are the major benefits of using foamed concrete?

A: The primary advantage is that frothed concrete is lighter in weight than routine concrete, which can result in substantial financial savings in building assistance costs. Furthermore, frothed concrete has far better thermal and acoustic insulation residential or commercial properties.

Q: Just how does frothed concrete devices job?

A: The tools utilizes a foam generator to create foam that presents air bubbles into the concrete mix. This foam is then mixed with the concrete mix to develop a lighter product.

Q: Can lathered concrete be made use of in all kinds of construction?

A: Foamed concrete is versatile and finest suited for applications where its lightweight attributes and thermal insulation homes are useful. It may not be the most effective option for load-bearing frameworks that need high compressive toughness.

Q: Is unique training required to operate foamed concrete tools?

A: Basic training is advised to understand the procedure and precaution of the maker. A lot more intricate systems may call for customized training to guarantee ideal efficiency and safety.

Q: Exactly how should frothed concrete tools be maintained?

A: Regular cleansing and maintenance are needed to stay clear of blocking and make certain the life of the equipment. Refer to the producer's standards for details upkeep standards.