Professional solutions on concrete addtives, Concrete Foaming Agent, Superplasticizer, CLC Blocks Additives, and foaming machine

PRODUCT PARAMETERS

Description

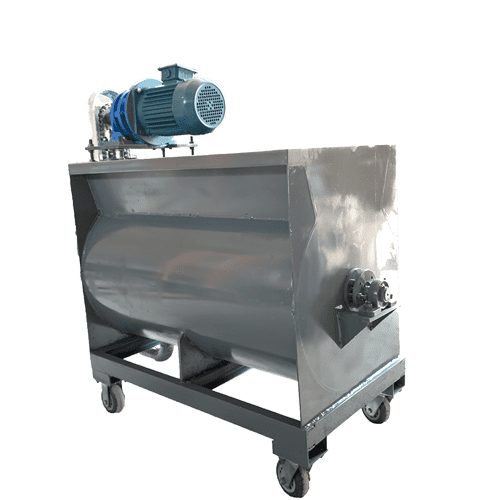

Product Description of Horizontal Mixer

TR-M300 concrete mixer is under the action of the inner and outer spiral belts on the mixing shaft to turn the material within the scope of the cylinder. The internal spiral belt pushes the material from the middle to the two sides, the outer spiral belt pushes the material from the two sides to the center, and the back-and-forth infiltrated material moves and changes along the radial direction under the rotation of the spiral belt, thus forming a convection cycle. Due to the stirring of the movement mentioned above, the materials can be quickly and uniformly mixed, the shaft seals at both ends are specially sealed, the powder and liquid have no leakage, and the replacement cost of the sealing consumables is low. The replacement is convenient, so it is a widely used, adaptable, High-efficiency mixing equipment with solid performance and sound effects.

How Does Horizontal Mixer Work?

The horizontal cylinder is equipped with double-shaft rotating and reversed paddles. The paddles are at a certain angle to stir the materials in the axial and radial directions so that the materials can be mixed quickly and evenly. Performance characteristics of the horizontal mixer: The paddle’s structure will weaken the material’s gravity. With the lack of seriousness, the differences in particle size and specific gravity of each material are ignored in the mixing process.

Intense stirring motion shortens the mixing time, making it faster and more efficient. Even if the material has specific gravity and particle size differences, it can achieve a good mixing effect under the rapid and violent tossing and throwing of the staggered stirring blades. It has high mixing uniformity and less residue and is suitable for mixing more than two kinds of fertilizers and additive premixes.

Features of Horizontal Mixer

The horizontal mixer makes the materials thoroughly mixed, thereby improving the mixing uniformity; using a novel rotor structure, the minimum gap between the rotor and the bright body can be adjusted to close to zero, effectively reducing the residual amount of materials. The material is broken, the overall structure is more reasonable, the appearance is beautiful, and the operation and maintenance party installs and maintains.

Company Profile

Cabr-Concrete is the global leader in Low-Density Cellular Concrete (LDCC), Celluar Light Concrete (CLC), and advanced engineered foam solutions. Known globally for its commitment to research, innovation, and applied expertise, we have been providing engineered foam solutions since the early 2012’s.

We can supply high-quality TR-11 Mini Foam Generator for CLC Blocks, TR75 7.5 kW CLC Foam Generator for Lightweight Concrete, TR30 CLC Foaming Machine Concrete Foam Generator, 13kw High Expansion Foam Generator, TR10 Concrete Blocks Making Machine and other concrete relative machines all over the world.

The company has a professional technical department and quality supervision department, a well-equipped laboratory, and equipped with advanced testing equipment and after-sales customer service center.Send us an email or click on the needed products to send an inquiry: sales@cabr-concrete.com

Payment

T/T, Western Union, Paypal, Credit Card etc.

Shipment

By air, by sea, by express, as customers request.

FAQs of Horizontal Mixer

Q1

What are the main components of a foam concrete horizontal mixer?

Answer:

The main components of the foam concrete horizontal mixer include mixing blades, mixing shaft, motor, reducer, frame, inlet and outlet, etc. These components work together to achieve the mixing and preparation of foam concrete.

Q2

How to choose a suitable foam concrete horizontal mixer?

Answer:

Choosing a suitable foam concrete horizontal mixer needs to consider factors such as production volume, characteristics of raw materials, motor power and reducer transmission ratio. Additionally, the reliability, ease of use, and maintainability of the blender should also be considered.

Q3

How to install and debug a foam concrete horizontal mixer?

Answer:

The installation and commissioning of the foam concrete horizontal mixer needs to be carried out in accordance with the instructions and operating guidelines. Generally speaking, it is necessary to fix the frame, install the motor and reducer, adjust the position and angle of the mixing blade, and conduct a trial run inspection.

Q4

How to use foam concrete horizontal mixer?

When using a foam concrete horizontal mixer, you should first add the raw materials to the feed port, start the motor, and control the mixing effect by adjusting the speed and working time. At the same time, it is necessary to pay attention to the working status of the machine and the quality of the foam concrete, and make timely adjustments.

Q5

What are the precautions for the maintenance and upkeep of foam concrete horizontal mixers?

Answer:

When maintaining and maintaining the foam concrete horizontal mixer, it is necessary to regularly check the wear of each component and replace seriously worn components in a timely manner. At the same time, the inside and outside of the machine need to be cleaned regularly to keep the machine in good working condition.

Q6

How to solve common fault problems of foam concrete horizontal mixer?

Answer:

Common fault problems include motor overheating, reducer oil leakage, loose mixing blades, etc. These issues need to be analyzed and dealt with on a case-by-case basis. For example, motor overheating may be caused by excessive load or poor heat dissipation, and the load needs to be reduced or heat dissipation enhanced; reducer oil leakage may be caused by damaged seals or excessive oil level, and the seals need to be replaced or the oil level adjusted.

Q7

What are the safety operating procedures for foam concrete horizontal mixers?

Answer:

Safe operating procedures include checking whether all parts of the machine are normal before use, wearing protective equipment, avoiding staying in dangerous areas or performing maintenance operations, etc. At the same time, you need to pay attention to the working status of the machine and stop it immediately for inspection if any abnormalities are found.

REQUEST A QUOTE

RELATED PRODUCTS

Foam Concrete Mixer Small Concrete Machine Mixer

Integrated Machine for Pouring Light Steel Keel and Structural Wall

TR-20 Lightweight Concrete Machine

TR30 CLC Foaming Machine Concrete Foam Generator

industrial design Equipment for making foam Foaming machine